Customised according to site area

MOQ: 500 square metres

Application: Silicone PU courts are a high-performance sports surface material that has seen widespread application in outdoor settings in recent years. They are particularly well-suited for ball sports venues such as basketball courts, tennis courts, badminton courts, and volleyball courts.

Description: Its outstanding elasticity, wear resistance, and slip-resistant properties provide athletes with a safe, comfortable athletic experience and protection. At the same time, its vibrant colors, exceptional durability, and easy maintenance make it an ideal choice for school and community sports facilities.

Silicone PU courts are sports surface systems made from siliconized polyurethane, currently recognized internationally as one of the best outdoor sports flooring materials. Its application features are detailed below:

1. Exceptional professional athletic performance:

Scientific Rebound and Shock Absorption: The unique resilient base layer structure of silicon PU material provides athletes with optimal elasticity. It effectively cushions impact forces during movement, reducing strain on joints such as ankles and knees. Simultaneously, it ensures consistent and precise ball rebound rates, meeting professional competition standards.

Superior Slip Resistance and Traction: The surface layer undergoes special treatment to deliver stable friction coefficients under all weather conditions. Whether dry or wet, athletes can execute sudden stops, starts, and turns without slipping, benefiting from powerful traction.

2. Long-lasting Durability and Cost-effectiveness:

Exceptional Weather Resistance: The product effectively resists UV rays, ozone, rain, and extreme temperatures. It maintains color, flexibility, and integrity without cracking or bubbling for over 8 years.

Outstanding Abrasion Resistance: The surface remains robust and wear-resistant against cleats and daily equipment use, maintaining its integrity over time and significantly reducing future refurbishment and maintenance costs.

3. Comprehensive Safety and Environmental Features:

Safety Assurance: Even in falls, its soft texture provides effective cushioning, minimizing risks of abrasions and other accidental injuries.

Eco-Friendly: Non-toxic and odorless materials comply with national environmental standards, qualifying as a green product that safeguards the health of both construction workers and athletes from the source.

4. Convenient Installation and Maintenance:

Tolerant Substrate Requirements: Can be directly applied over well-quality concrete or asphalt bases, compensating for minor substrate imperfections to some extent.

Simple Maintenance: Routine cleaning is effortless—simply rinse with water to restore a pristine appearance, requiring no special upkeep.

5. Aesthetic Visual Appeal:

Featuring rich, soft hues (e.g., iron red, green, blue) and crisp, distinct lines, it clearly delineates playing areas while enhancing the surrounding environment. This elevates the venue’s professionalism and visual appeal.

| Performance Specifications | Unit | Standard Requirements |

| Hardness (Shore A) | – | 45-65 |

| Rebound Value | % | ≥ 20 |

| Tensile Strength | MPa | ≥ 0.7 |

| Elongation at Break | % | ≥ 90 |

| Compression Set | % | ≥ 90 |

| Abrasion Resistance | mm³ | ≤ 150 |

| Flame Retardancy | Grade | 1 |

| Slip Resistance (Wet) | BPN | ≥ 47 |

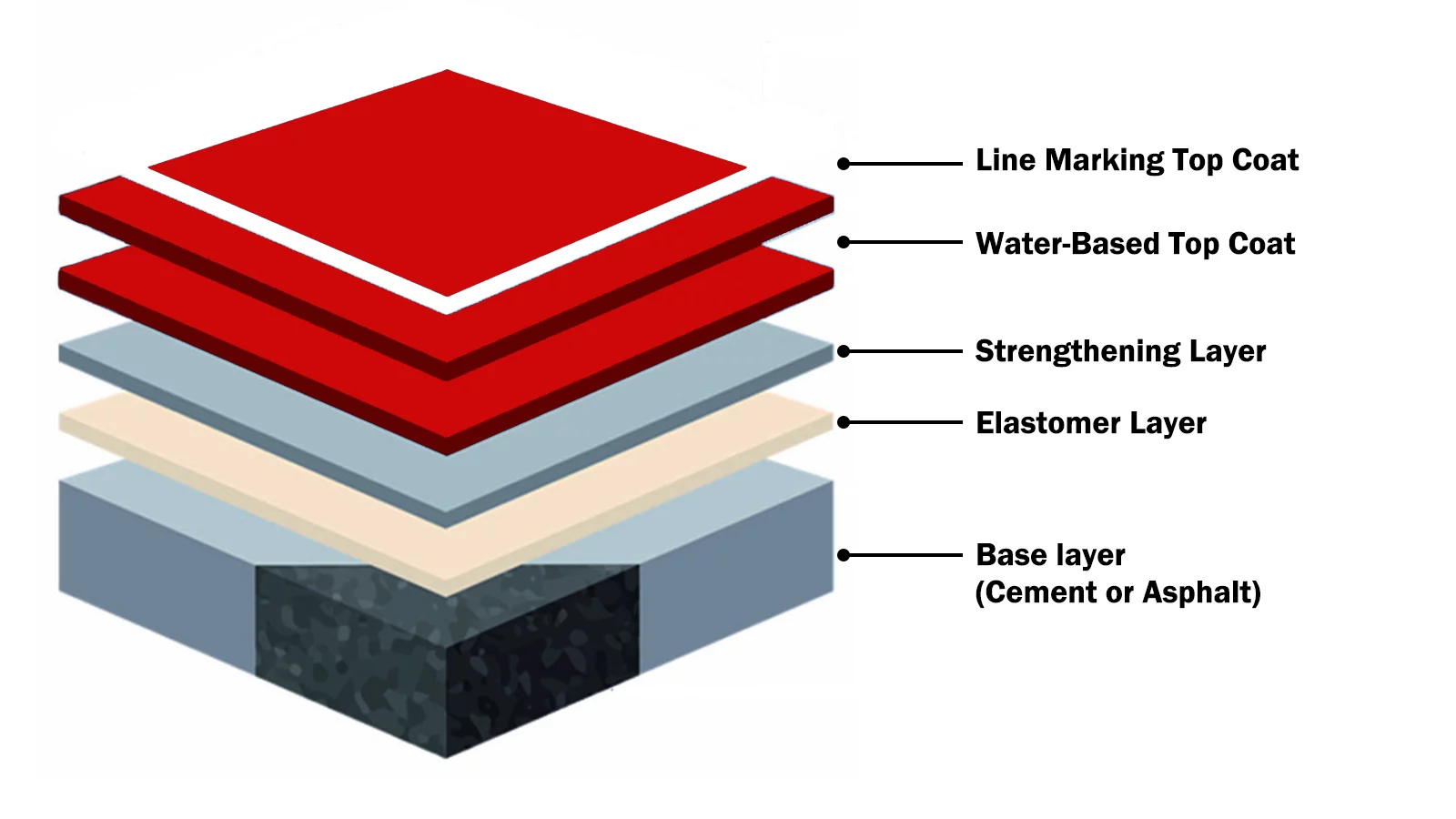

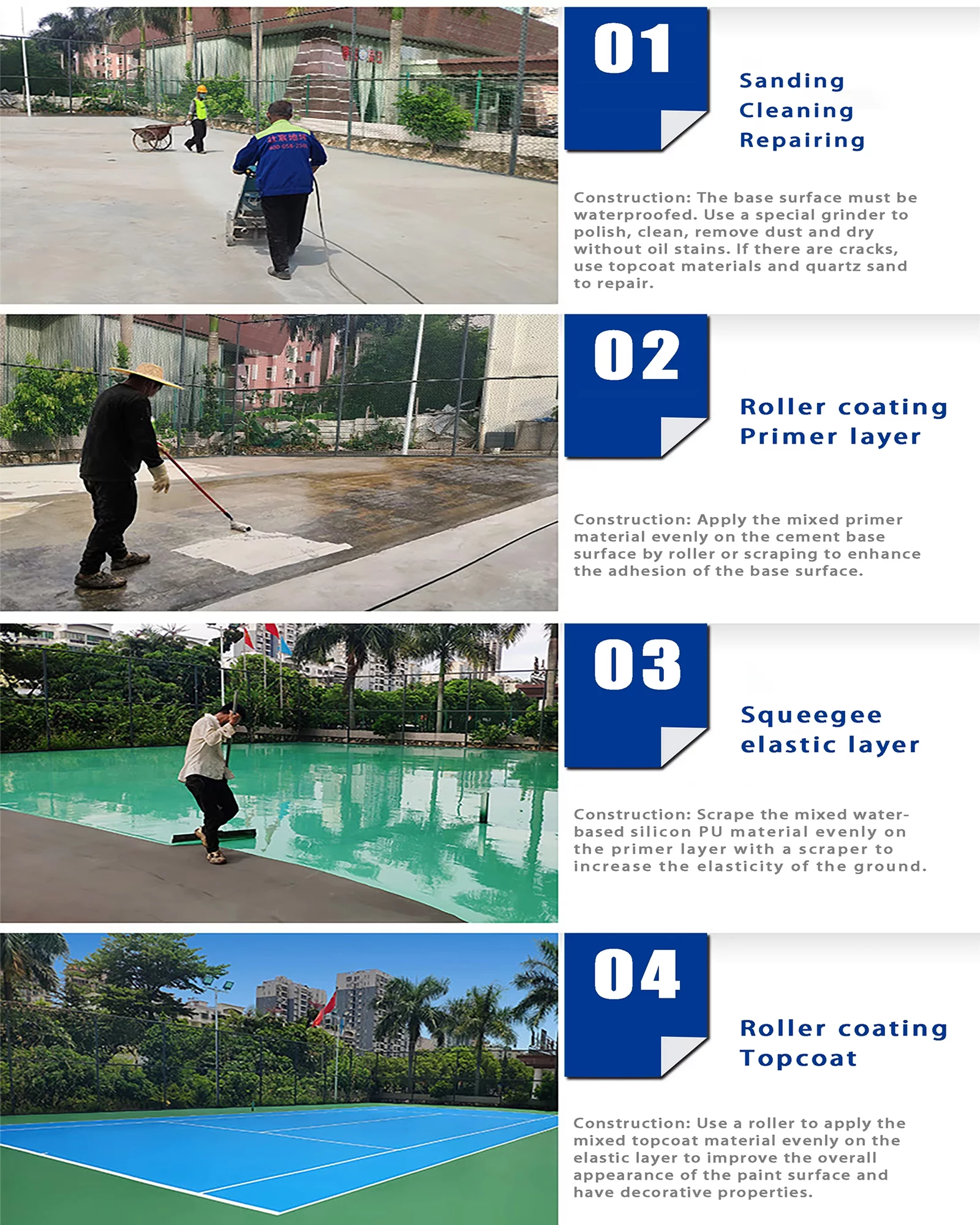

1. Substrate Preparation: Ensure the base layer is solid, level, and dry. Clean the surface, grind and repair cracks and pits, and maintain proper drainage slope.

2. Primer Application: Penetrate and seal the substrate to enhance cement strength and improve adhesion with subsequent materials.

3. Elastic Layer Installation: Core cushioning layer. Apply silicone PU elastic material by trowel to provide court rebound and impact absorption.

4. Reinforcement Layer Application: (Optional) Apply an additional layer over the elastic layer to further enhance the court’s strength and resilience.

5. Topcoat Application: The functional layer. Apply a colored topcoat to deliver superior abrasion resistance, weather resistance, and slip resistance.

6. Line Marking: Measure and mark positions according to standard court dimensions. Apply markings using specialized line paint.

7. Site Clearance & Curing: Clear the construction area, cordon off the site, and allow natural curing for 5-7 days before use.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000