Customized by Site Size

MOQ:From 500 square metres

Type: Sandwich System Running Track (13-15mm)

Color :Red ,Green,Blue, Other Color

Description:10mm black SBR base/mat layer ,pore sealed with PU4:1 plus EPDM dust and a 3-4mm full pour top coat with 1-4 mm EPDM granule

Can add Spray-coat layer for top layer protect

| Product Name | Sandwich System Running Track | Product rubber content | Top/30% (±1%), Bottom/40% (±1 %) |

| Feature | Most economical, all weather use, good flatness, perfect for cold area | Impact absorption(%) | 38%(±1%) |

| Base | Cement or asphalt | Vertical deformation(mm) | 1.74mm(±0.1mm) |

| Color | Red, Blue, Purple, Green and customized | Tensile strength(Mpa) | 0.8Mpa(±0.1Mpa) |

| Thickness | 9-15.9MM(or customized) | Tensile elongation(%) | 100%(±5%) |

| Warranty | 2 Years | Shore hardness(°) | 52° |

| Certificate | IAAF | Anti-slip value | ≥57 BPN20℃ |

| Application | Stadium, sports ground, sport center, schools, jogging park and so on. | Fire resistance | 1 Grade |

Sandwich system plastic running track sports field because it has a good surface drainage function, the rain and snow in the alpine region into the elastic layer of the plastic runway, once the climate warms up, snow and ice melt in the surface of the sandwich plastic runway through the natural drainage of the runway slope, the runway does not have any adverse effects. Applicable to all kinds of athletic field in the alpine area.

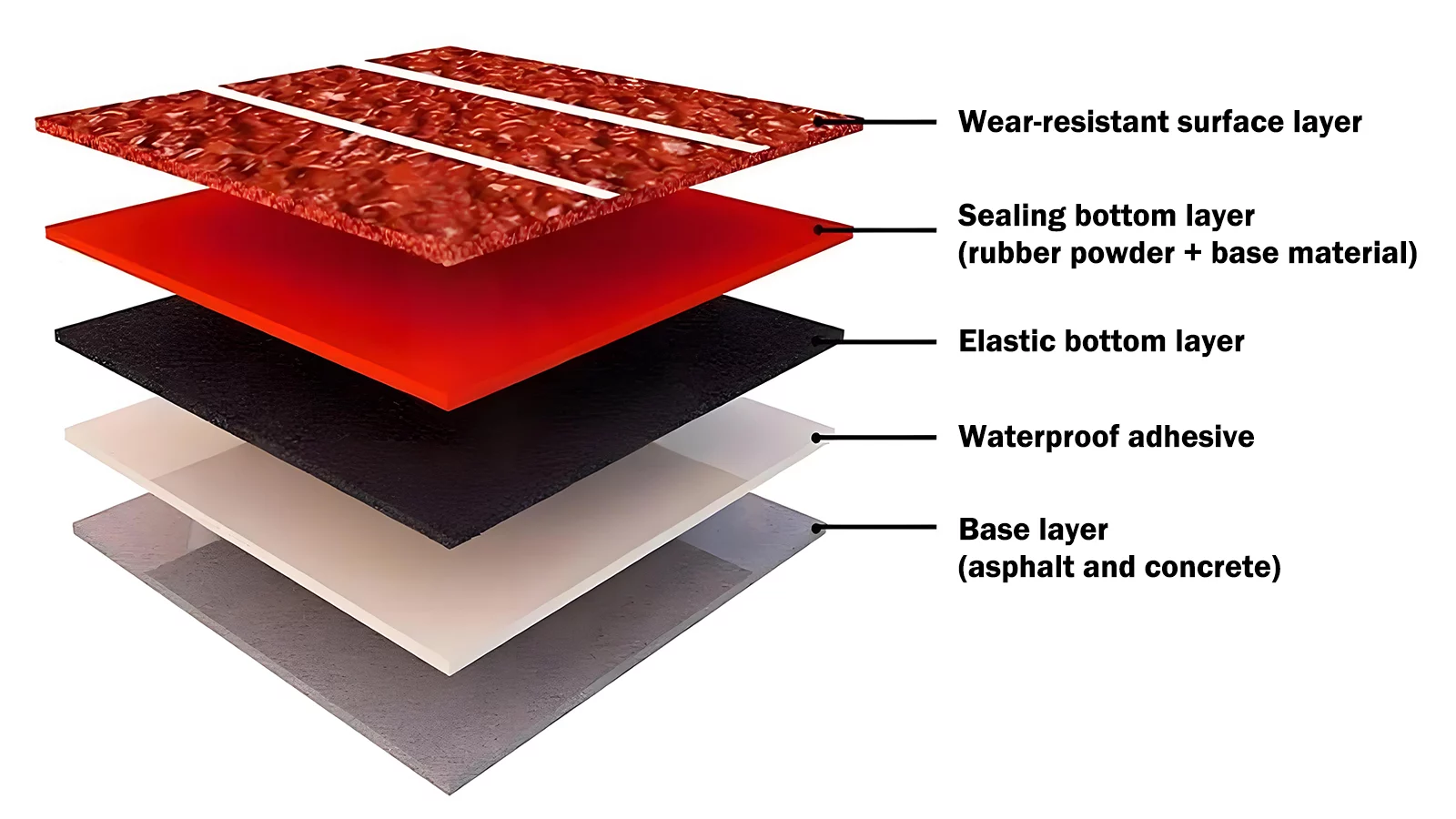

1. Layered composite structure: bottom elastic particles + middle reinforcing layer + surface wear-resistant layer, scientific layered design.

2. On-site liquid construction: raw materials are laid in liquid state, seamless curing and shaping, strong integrality.

3. Highly adaptable foundation: low levelling requirements for asphalt/concrete foundation, saving the cost of grass-roots treatment.

4. Excellent comprehensive performance: taking into account the elasticity, impact resistance, abrasion resistance and anti-skid.

5. Convenient and economical maintenance: local damage can be seamlessly repaired, low maintenance cost and low impact.

6. Environmentally friendly, durable and reliable: environmentally friendly and non-toxic materials, weathering and anti-aging, long service life.

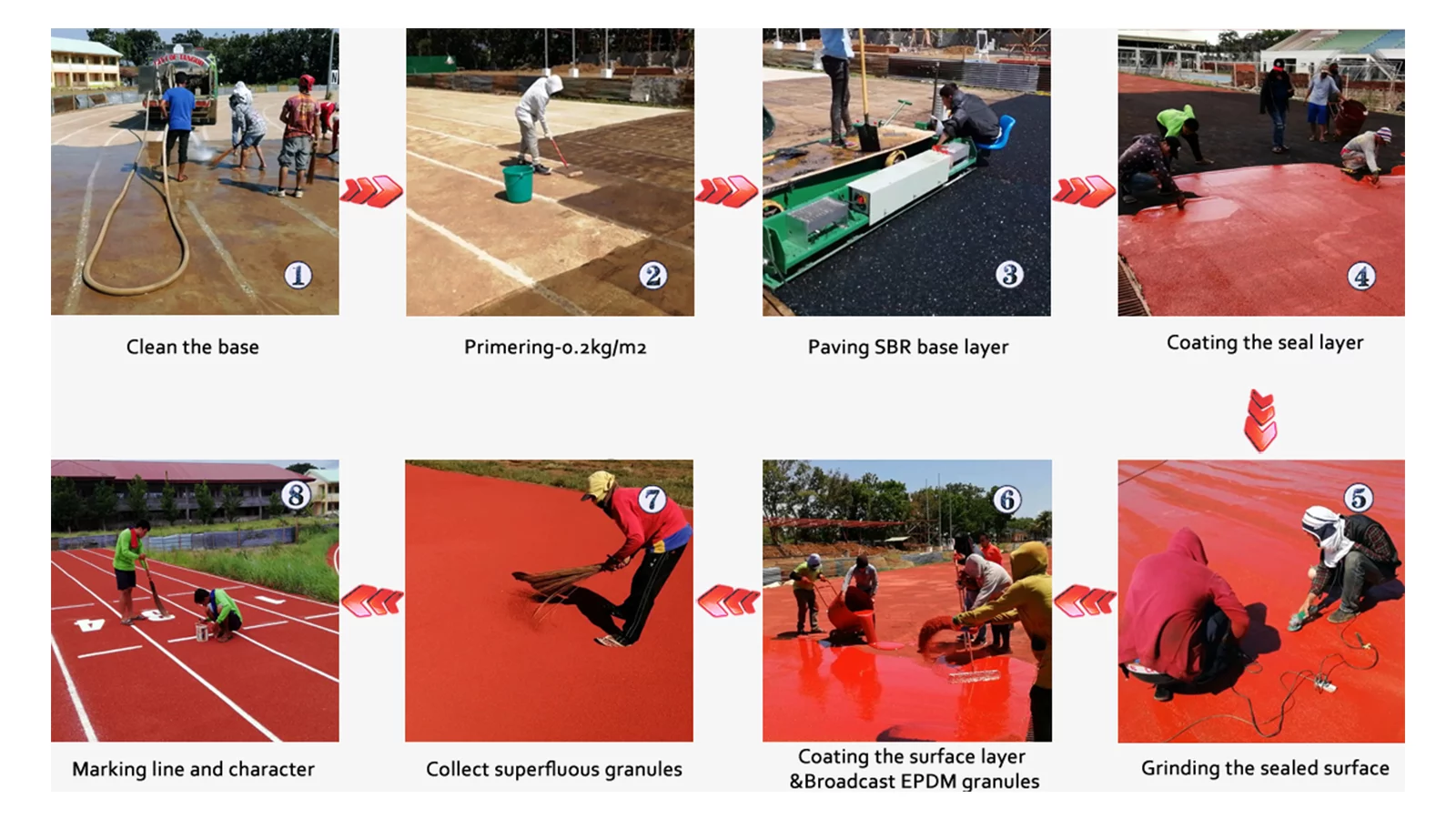

1. Clean foundation (asphalt/concrete), repair cracks and holes.

2. Key: test the foundation strength, flatness, water content (must meet the standard).

1. Roll on special primer material to enhance bonding with foundation and close capillary holes.

1. Mix polyurethane glue + rubber granules, paving and scraping.

2. Core: control thickness, flatness and elasticity.

1. Scrape and apply high-strength polyurethane slurry layer to form a dense intermediate layer.

2. Role: to improve the overall strength, tear resistance, flatness.

1. Spraying method: mixed surface layer slurry + EPDM particles, spraying to form texture.

2. Scraping method: scraping with sand surface layer slurry, sprinkle anti-skid particles (optional).

3. Core: uniformity, anti-skid, weather resistance, color consistency.

1. Measure and position according to standard size, spray professional sports delineation paint.

1.Clean up the site, fully cured (usually takes 5-7 days) before use.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000