Customized by Site Size

MOQ: From 500 square metres

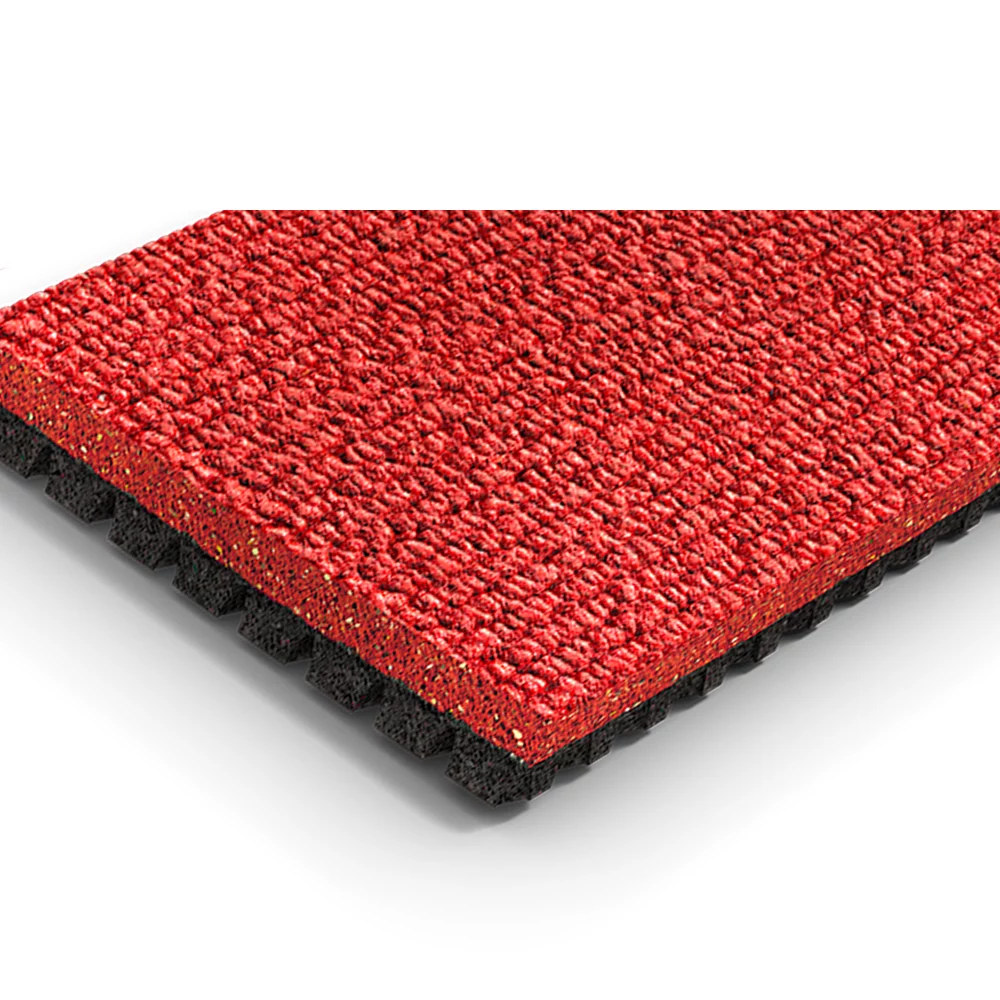

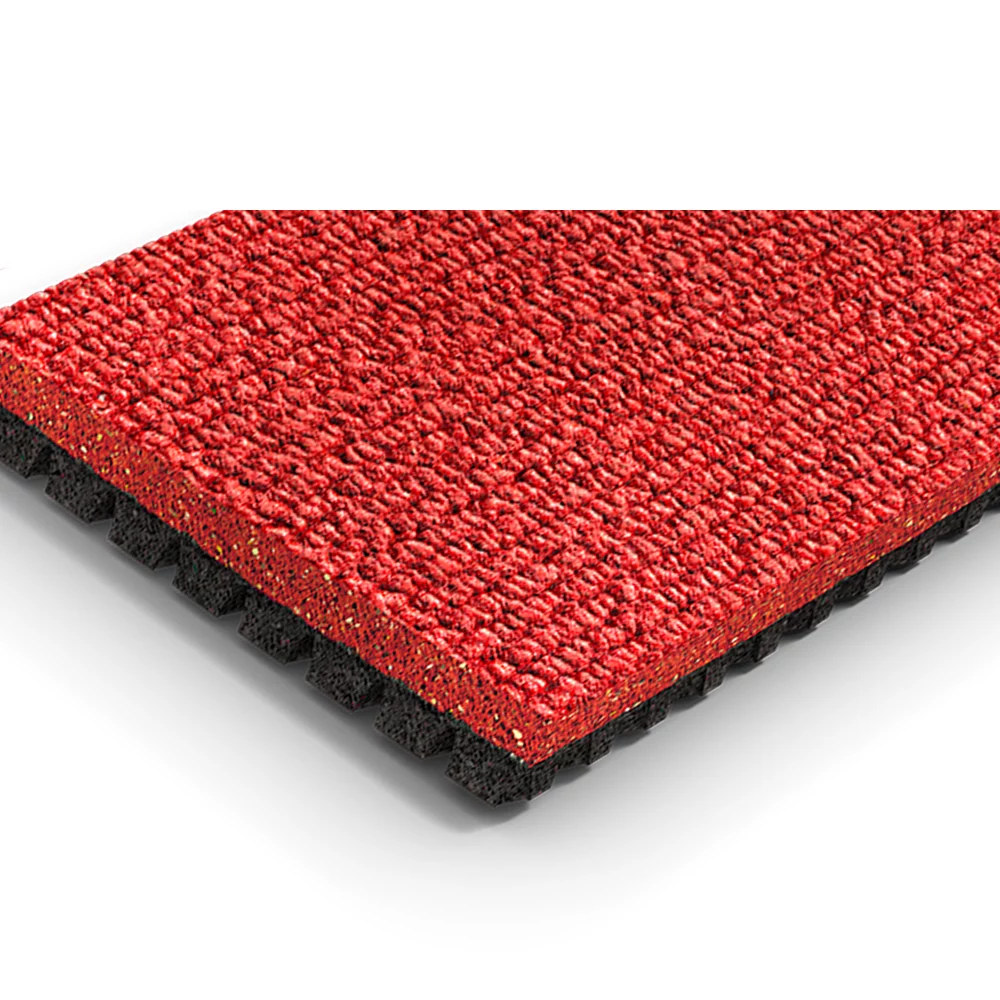

Item: Prefabricated Rubber Running Track

Material: Natural rubber

Thickness: 13mm(4+9) or customized

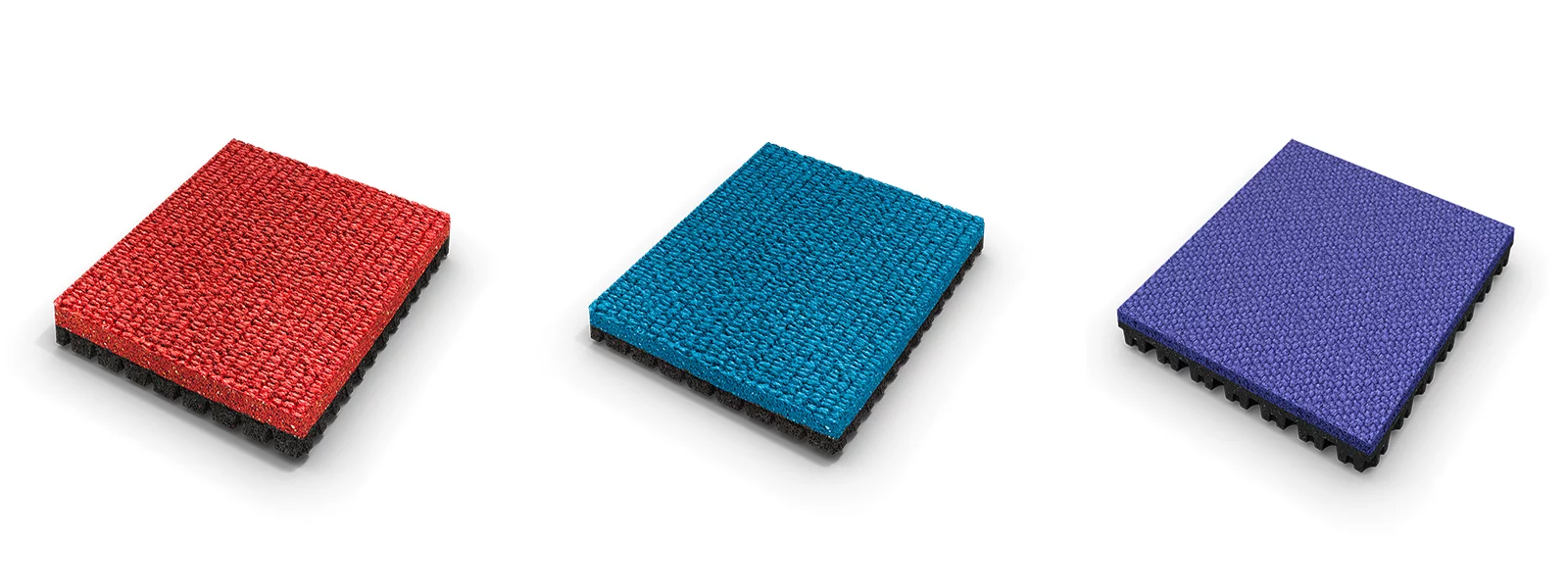

Surface Color: Red, Blue, Green, Purple, Grey

Bottom Color: Gray, Brown, Black

| Product Name | Prefabricated System Running Track | Product rubber content | Top/60% (±1%), Bottom/55% (±1 %) |

| Feature | Prefabricated for easy installation, great sports performance, safe, eco-friendly | Impact absorption(%) | 41%(±1%) |

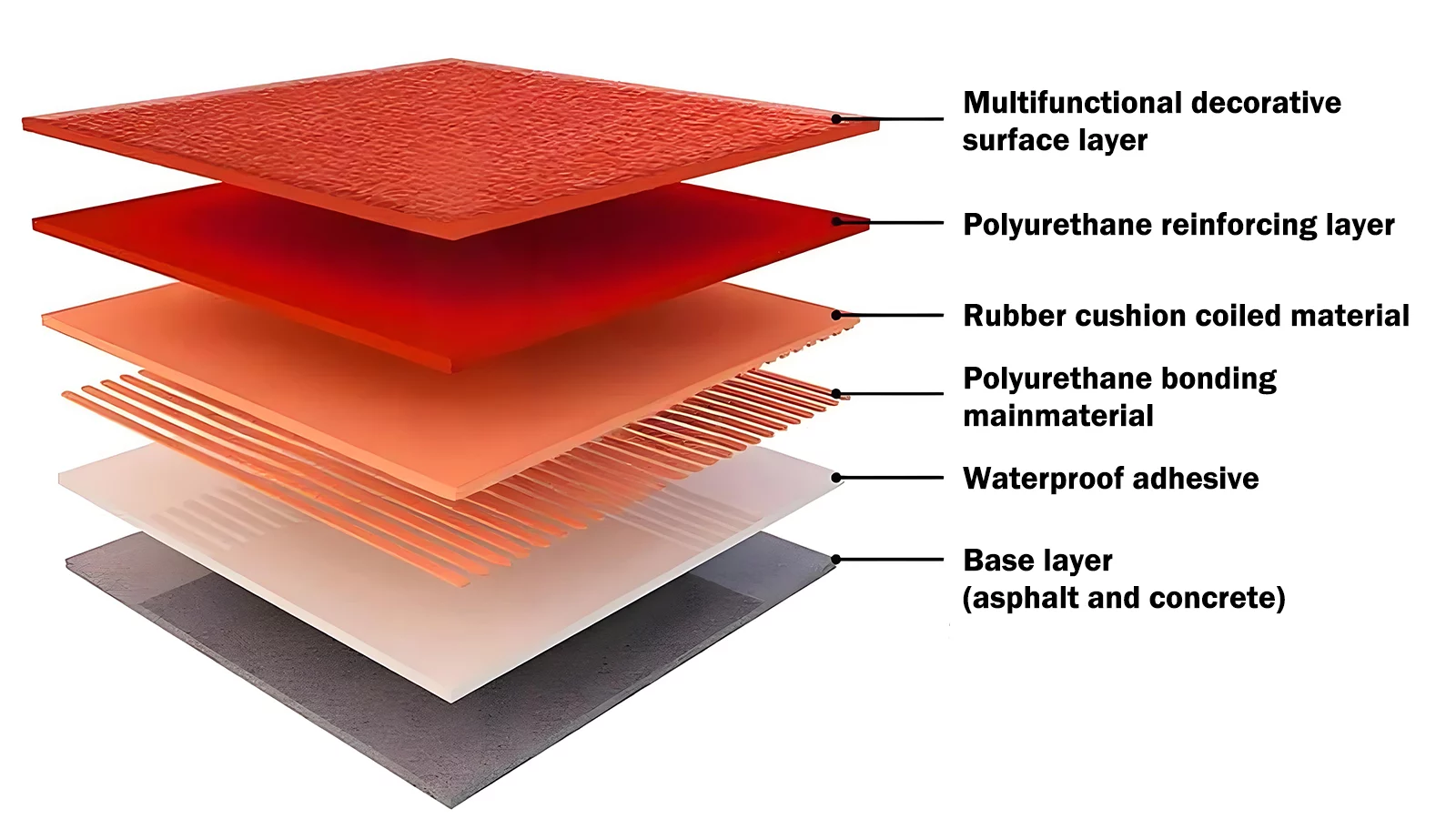

| Base | Cement or asphalt | Vertical deformation(mm) | 1.6mm(±1mm) |

| Color | Red, Blue, Purple, Green and customized | Tensile strength(Mpa) | 1.17Mpa(±0.1Mpa) |

| Thickness | 9-15.9MM(or customized) | Tensile elongation(%) | 235%(±20%) |

| Warranty | 2 Years | Shore hardness(°) | 55° |

| Certificate | IAAF | Anti-slip value | ≥47 BPN20℃ |

| Application | Stadium, sports ground, sport center, schools, jogging park and so on. | Fire resistance | 1 Grade |

1. No rubber particles, no degranulation, ideal for frequent use

2. Good shock absorption, excellent rebound performance, good adhesion, strong resistance to spikes.

3. Anti-slip, wear-resistant performance, even in rainy days performance is not affected

4. Extraordinary anti-aging, anti-ultraviolet light ability, the colour is durable and stable matte surface, no reflection of light, no dazzling feeling

5. Prefabricated moulding, easy to install

6. All-weather use, long service life, easy maintenance, low maintenance costs.

7. Flame retardant, insulation, sound insulation performance, fire prevention, high safety performance

8. Non-toxic, harmless, in line with environmental requirements

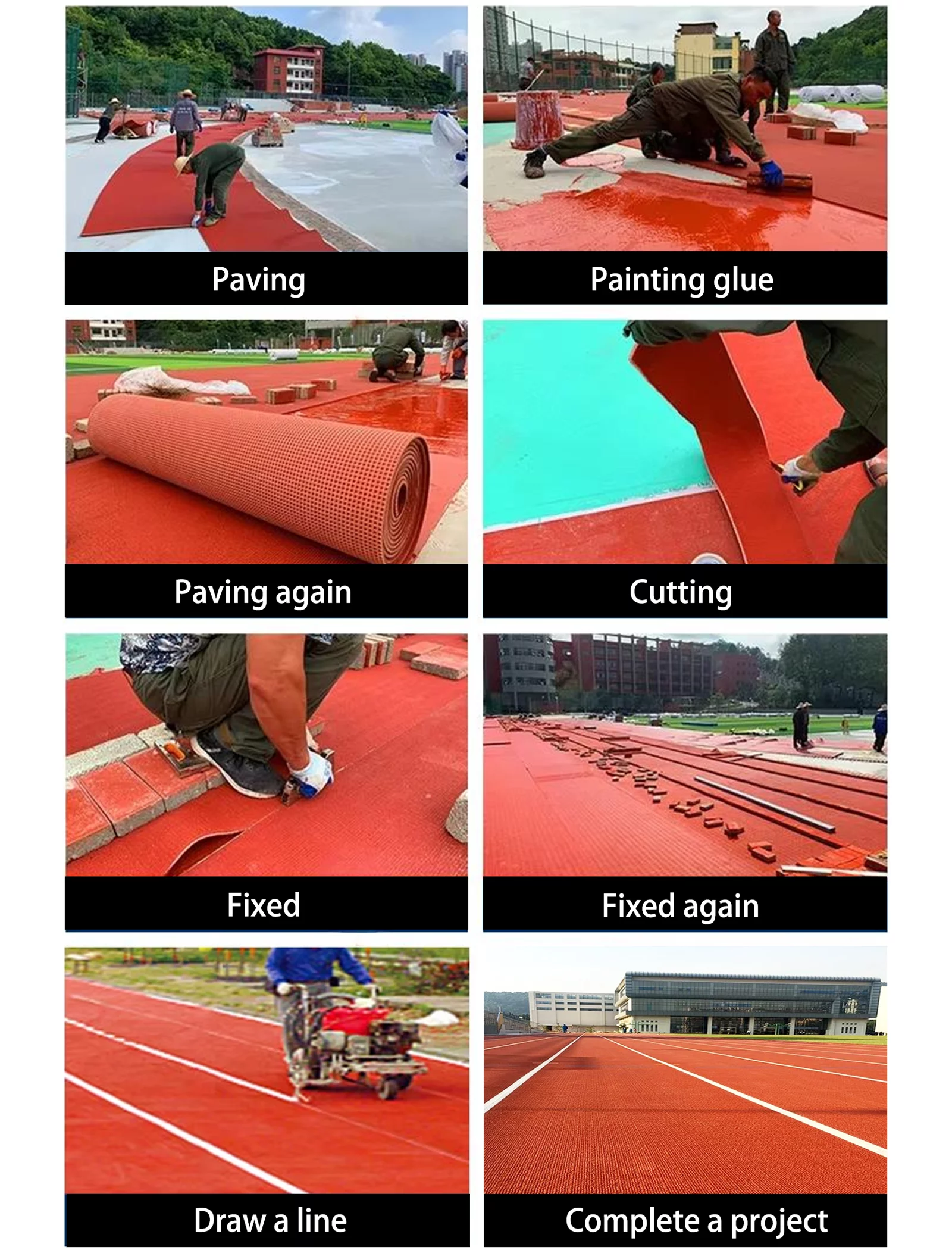

1. Clean up the site and make sure the base (concrete or asphalt) is level, solid and free of oil and dirt.

2. Repair cracks and potholes, and polish raised parts.

1. Check the flatness (3m straightedge error ≤ 3mm), slope (0.5%~1%), strength (concrete ≥ C25, asphalt dense).

2. Moisture content ≤8% (need to dry).

Uniformly roll and apply special polyurethane bonding agent on clean grassroots (according to manufacturer’s proportion).

1. Align the lines and lay the coil from the inside to the outside of the runway.

2. Compact the coil while paving (use a heavy-duty roller to eliminate air) to ensure that there are no bubbles or wrinkles.

3. Reserve 1~3mm thermal expansion joints at the splicing of adjacent coil materials.

1. Use two-component polyurethane caulking adhesive to fill the gap, scraping and sealing.

2. Focus on compaction of seam edges (hot welding or cold bonding process according to manufacturer’s requirements).

1. Position the line according to the design drawings by sticking the patterned paper and spray white/colorful polyurethane line drawing paint.

2. Remove the paper after curing.

Remove debris and close the site for maintenance for ≥48 hours (avoid stepping and drenching).

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000