Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Floor treatment for extreme working environments such as food processing, slaughterhouses, heavy-duty corrosion protection, and high-humidity/high-temperature conditions, as well as all workshop, warehouse, parking garage, and laboratory floors requiring abrasion resistance, cleanliness, and chemical resistance.

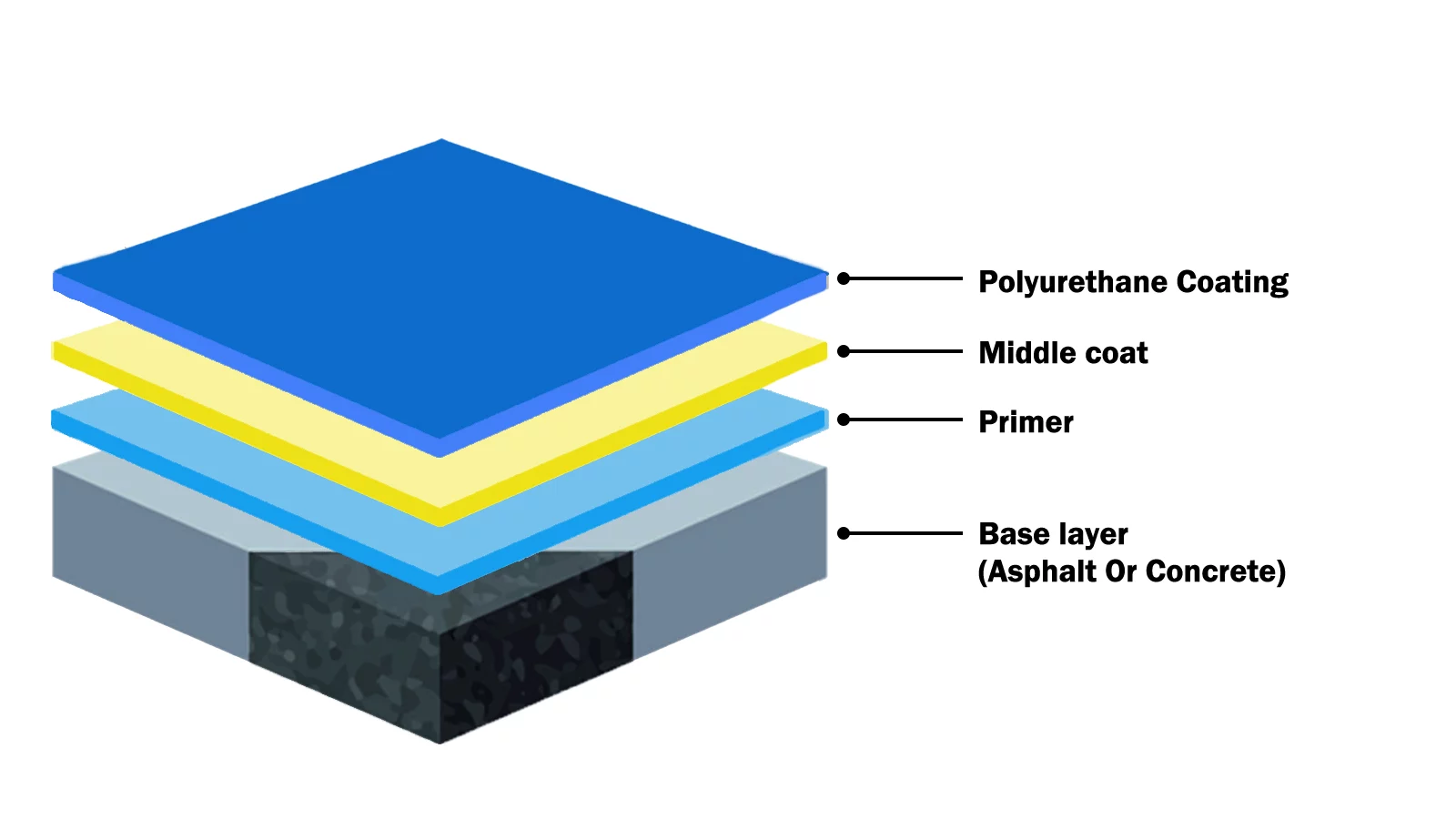

Description:Wear-Resistant Polyurethane Mortar Self-Leveling Compound is a four-component water-based polyurethane mortar flooring material. Its composite structure combines all the advantages of organic polymers and inorganic concrete materials, such as excellent resistance to chemical corrosion, heavy impact, and thermal shock.

Polyurethane ultra-wear-resistant flooring is a ground system featuring high-performance polyurethane as its core material. It exhibits exceptional abrasion resistance and impact resistance, with a wear index several times higher than standard epoxy flooring. Additionally, it offers outstanding flexibility, resistance to extreme temperature fluctuations, and chemical corrosion. Its seamless, dust-proof surface facilitates easy cleaning and maintenance. Ideal for environments demanding exceptional wear resistance and durability—such as heavy machinery workshops, logistics warehouses, parking facilities, and large commercial spaces—it stands as a benchmark for durability in industrial flooring.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=2:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

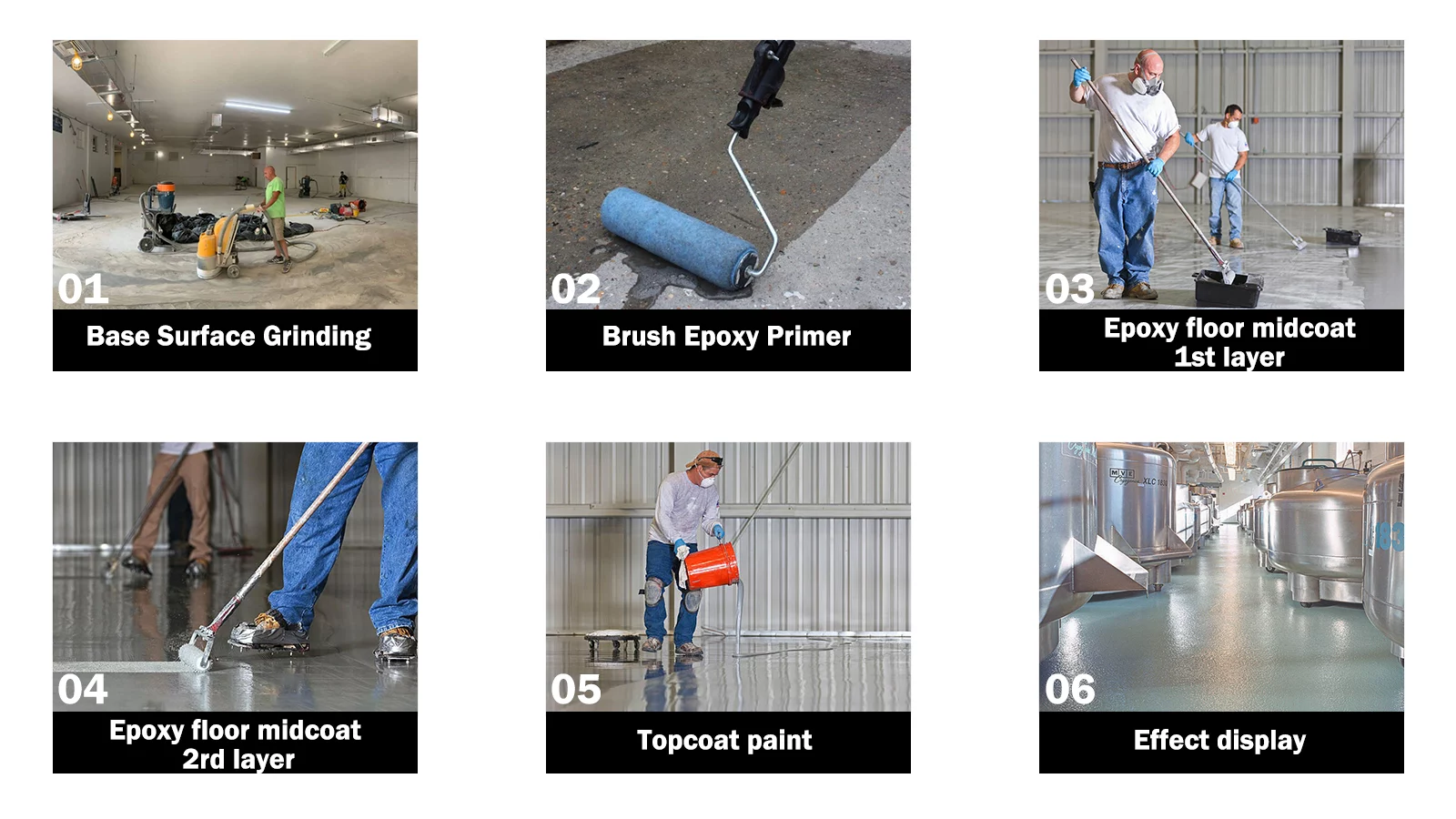

1. Substrate Preparation: Roughly grind the substrate mechanically until level. Remove loose particles, oil stains, and floating mortar. Repair cracks and pits to ensure the surface is dry and free of hollow areas.

2. Epoxy Primer: Apply using roller or trowel techniques to enhance substrate adhesion and sealing properties, providing a solid bonding foundation for subsequent coatings;

3. Epoxy Intermediate Coat: Apply using trowel or squeegee techniques to enhance wear and impact resistance, fill substrate defects, and improve surface levelness;

4. Fine grinding and dust removal: Mechanically grind to eliminate loose sand, particles, and residues from the intermediate coat while smoothing out scratches and unevenness to enhance floor flatness;

5. Epoxy putty: Apply using a trowel to achieve precise leveling of the mortar intermediate coat, effectively eliminating microscopic surface irregularities and sealing fine pores;

6. Epoxy Topcoat: Applied via trowel or roller coating to form a dense protective layer, ensuring the overall performance of the flooring system;

7. Polyurethane Clear Coat: Applied via roller coating to form a protective layer over the topcoat, significantly enhancing scratch resistance and abrasion resistance.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000