Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios: Suitable for soccer training facilities, schools, communities, indoor soccer fields, sports centers, and sports event soccer fields.

Description: As a leading football turf manufacturer, we provide professionally designed football turf construction solutions to enhance any football field with a durable, professional-grade playing surface, delivering a perfect experience.

| Inspection Items | Parameters | Inspection Items | Parameters |

| Pile Height | 50 mm ± 1mm | Pile Height | 50 mm ± 1mm |

| Ture Gauge | 5/8 inches ± 3% | Ture Gauge | 5/8 inches ± 3% |

| Stitch Rate | 13/10 cm ± 3% | Stitch Rate | 14/10 cm ± 3% |

| Density/㎡ | 8190 ± 10% | Density/㎡ | 8820 ± 10% |

| Dtex | PE12000 / PE14000 | Dtex | PE16000 |

| Backing | Double PP Cloth + Black PU | Backing | Double PP Cloth + Black PU |

Professional Artificial Turf Soccer Field System Solutions Provider

We are dedicated to delivering high-standard, high-performance artificial turf soccer field systems to clients worldwide. From elite professional club training facilities to community and campus stadiums, we offer comprehensive one-stop services integrating premium materials, professional design, precision installation, and ongoing maintenance. All our products carry FIFA quality certification, ensuring exceptional athletic performance, outstanding safety, and enduring durability—empowering every soccer dream to reach its full potential.

1. Site Preparation: Level and compact the ground to ensure a solid, even foundation with adequate drainage gradient.

2. Drainage System Installation: Lay drainage pipes and channels to ensure efficient water runoff without pooling.

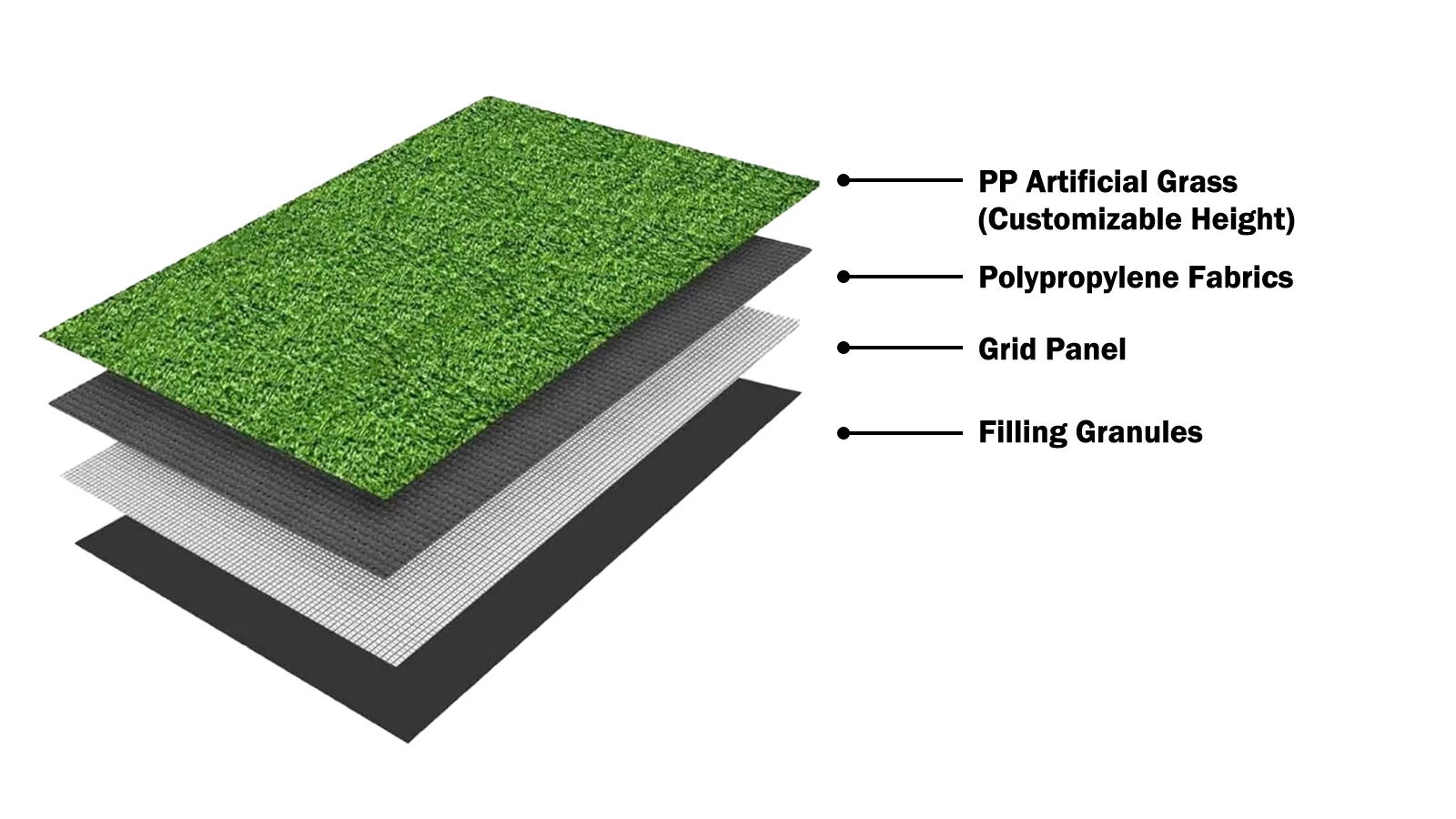

3. Base Layer Construction: Typically comprises a crushed stone layer and asphalt concrete layer, providing a stable, load-bearing foundation.

4. Artificial Turf Installation: Unroll and join turf rolls, ensuring consistent pile direction with tight, flush seams.

5. Line Marking: Cut turf to specification and embed white turf lines for pitch demarcation.

6. Infill Application: First apply quartz sand (to stabilise the pile), followed by elastic granules (for cushioning and underfoot feel).

7. Brushing and Inspection: Use specialised equipment to brush the grass fibres, ensuring even distribution of infill material, followed by final quality inspection.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000