Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios: GMP pharmaceutical plants, hospitals, blood product facilities and other cleanrooms; precision machinery and microelectronics manufacturing plants; areas with high requirements for mechanical and chemical performance.

Description:

1. Wear-resistant, pressure-resistant, impact-resistant, heat-resistant, waterproof, and possessing a degree of elasticity;

2. The epoxy floor coating surface layer is applied in a single-pass process, ensuring rapid and convenient installation.

Epoxy self-levelling flooring constitutes a premium industrial flooring system. This liquid coating relies on its own weight and high flow properties to self-level, forming an exceptionally smooth, seamless, and mirror-like finish. It not only offers significantly superior wear resistance, corrosion resistance, and impact resistance compared to standard coated floors but also meets the stringent requirements of highly clean, dust-free, and sterile environments. It is widely used in workshops across pharmaceutical, electronics, food processing, precision manufacturing industries, and high-end commercial spaces.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=3:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

| Available Time | 0.5H (10℃) | 0.4H(25℃) | 0.25H(30℃) | |

| VOC | ≤2%(After mixing) | |||

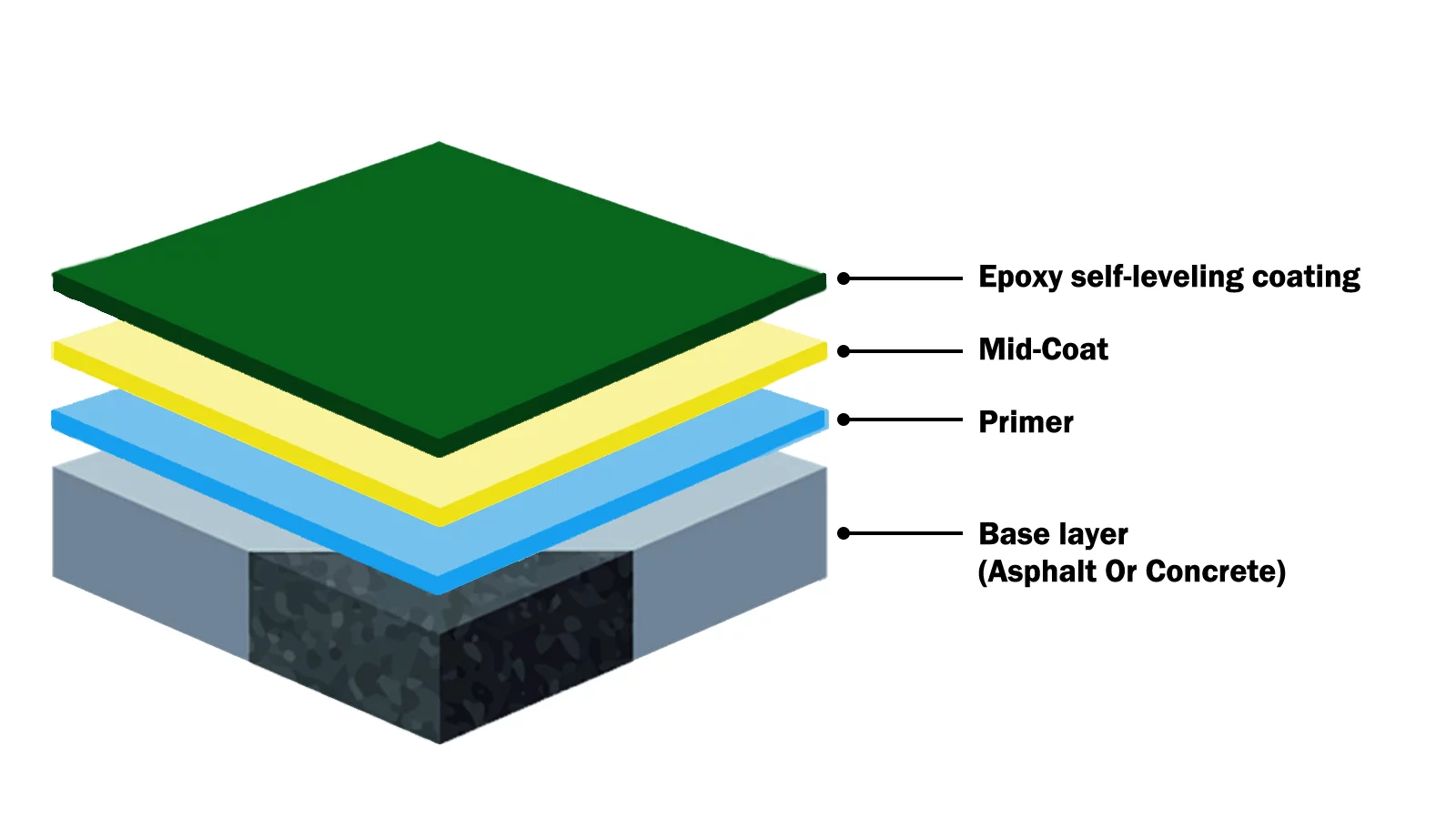

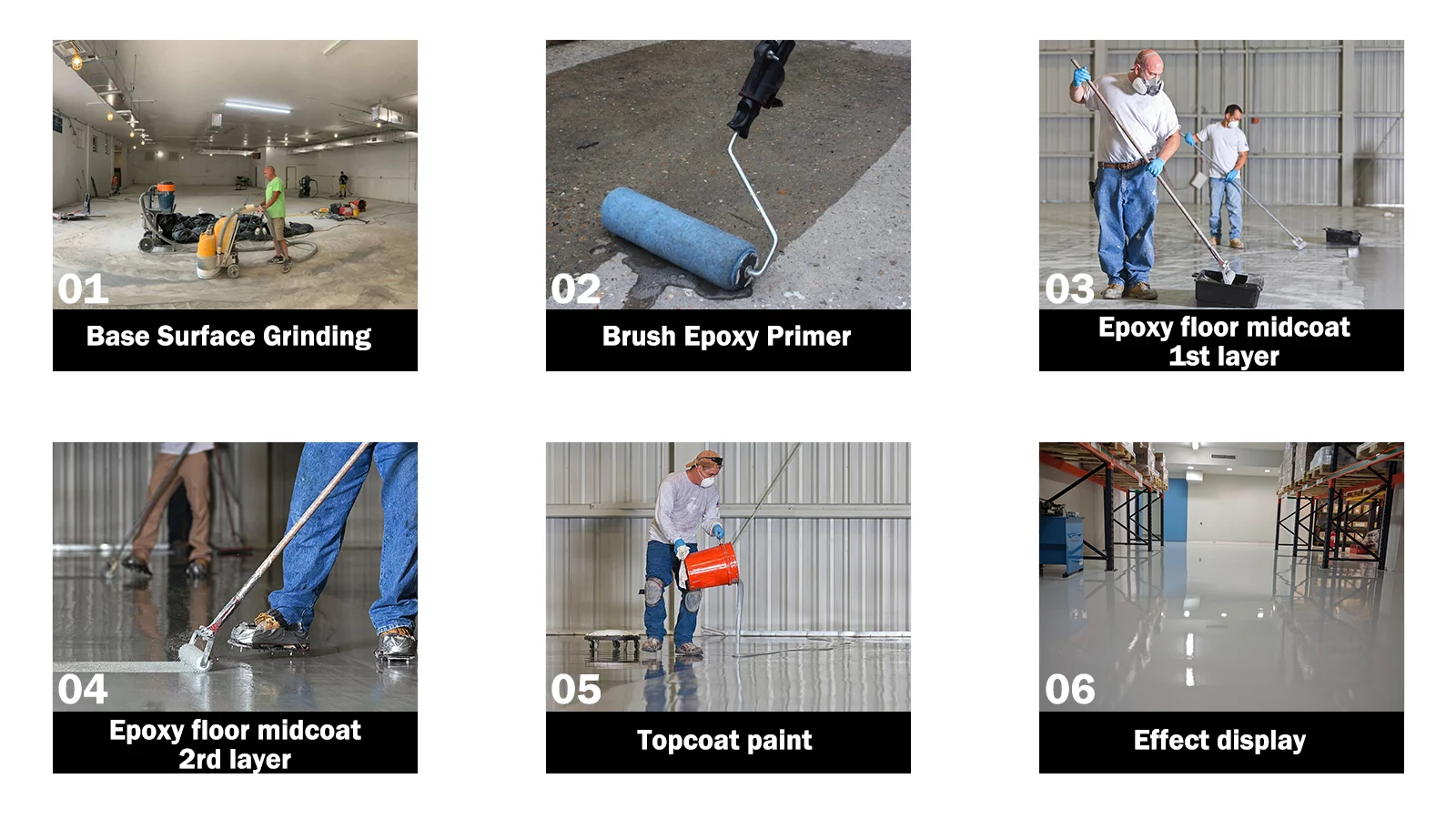

1. Substrate Preparation: The concrete substrate undergoes meticulous grinding and cleaning to thoroughly remove laitance and oil contamination. Cracks and pits are repaired to ensure the base is robust, level, and clean – the foundation for achieving the final finish.

2. Primer Application: A high-performance epoxy primer is rolled onto the surface, allowing it to fully penetrate the substrate. This serves a crucial role in reinforcing the base, sealing the surface, and bonding subsequent coatings.

3. Self-levelling Coating Application: Pour the prepared solvent-free epoxy self-levelling coating onto the floor. Guide the flow using a specialised notched trowel, allowing the material’s inherent fluidity to create an exceptionally flat, smooth, and seamless surface.

4. Curing: After application, allow the surface to rest and cure naturally. The area must be sealed off during this period to prevent dust and moisture interference until the coating achieves sufficient strength for foot traffic and use.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000