Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Flooring for special locations such as supermarkets, building lobbies, warehouses, car showrooms, auto repair shops, and parking garages.

Description:Smooth and glossy appearance with diverse color options; Seamless design for easy cleaning and maintenance.

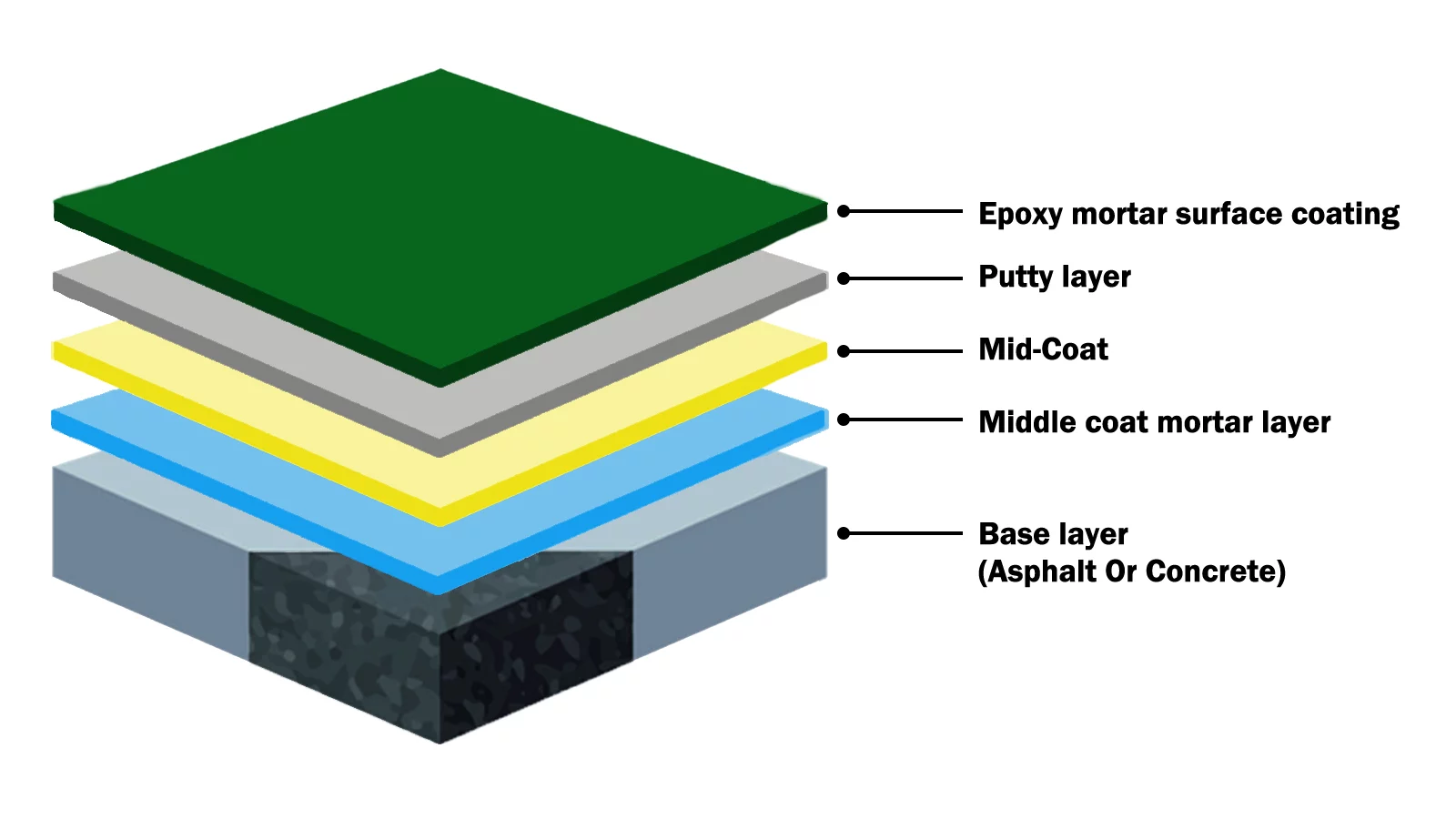

Epoxy mortar flooring is a high-strength, ultra-wear-resistant industrial flooring solution. By incorporating quartz sand of varying particle sizes into epoxy resin and applying it as a thick mortar intermediate layer, it achieves exceptional impact resistance, heavy-load bearing capacity, and abrasion resistance. The surface is robust and durable, featuring a seamless, dust-proof finish that is easy to clean. It is particularly suitable for industrial workshops, warehouses, logistics centers, and parking lots that frequently endure heavy vehicle traffic, mechanical equipment impacts, and high-intensity abrasion.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.20±0.05 | 0..85~0.90 | ||

| Ratio | Component A/Component A=3:1 | |||

| Solid | 98%以上 | |||

| Curing time | Surface-Dry | 16H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

| Available Time | 2.5H (10℃) | 30 Min(25℃) | 20 Min(30℃) | |

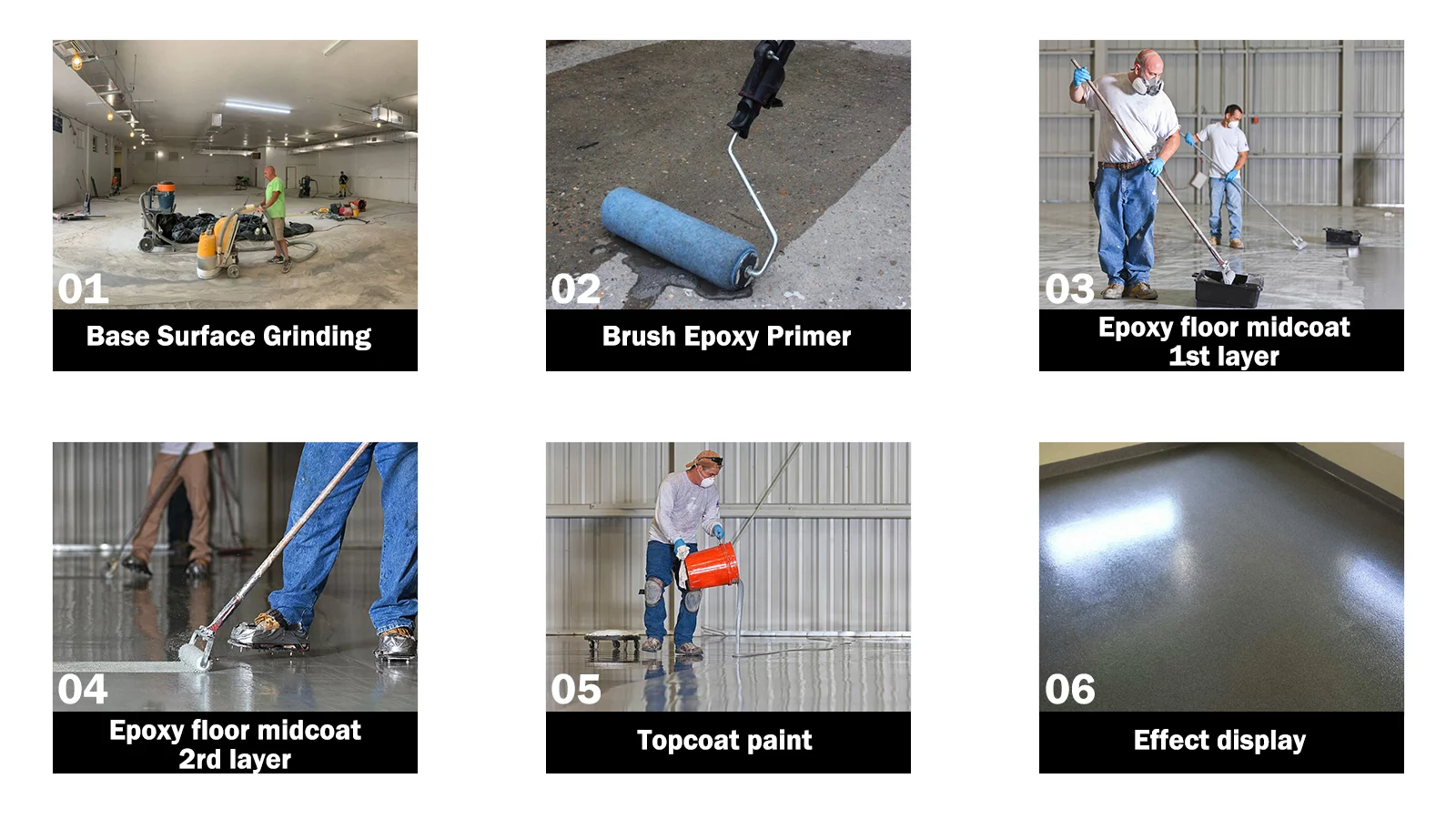

1. Substrate Preparation: Mechanically rough-grind the substrate to achieve a level surface. Remove laitance, oil stains, loose particles, and repair cracks and pits. Ensure the surface is dry and free of hollow areas.

2. Epoxy Primer: Apply using roller or trowel techniques to enhance substrate adhesion and sealing properties, providing a solid bonding foundation for subsequent coatings.

3. Epoxy Intermediate Coat: Applied by troweling or scraping to enhance abrasion and impact resistance, fill substrate imperfections, and improve surface levelness.

4. Fine Grinding and Dust Removal: Mechanically grind the intermediate coat to remove loose particles, residual debris, and eliminate scratches or unevenness, enhancing floor flatness.

5. Epoxy Putty: Applied by troweling to achieve precise leveling of the intermediate coat, effectively eliminating microscopic surface irregularities and sealing fine pores;

6. Epoxy Topcoat: Applied by rolling to form a high-density protective layer that blocks media penetration, ensuring the comprehensive performance of the flooring system.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000