Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:For use in garages, home interiors, basements, restaurants, breweries and distilleries, showrooms, retail spaces, offices, warehouses, clinical kitchens

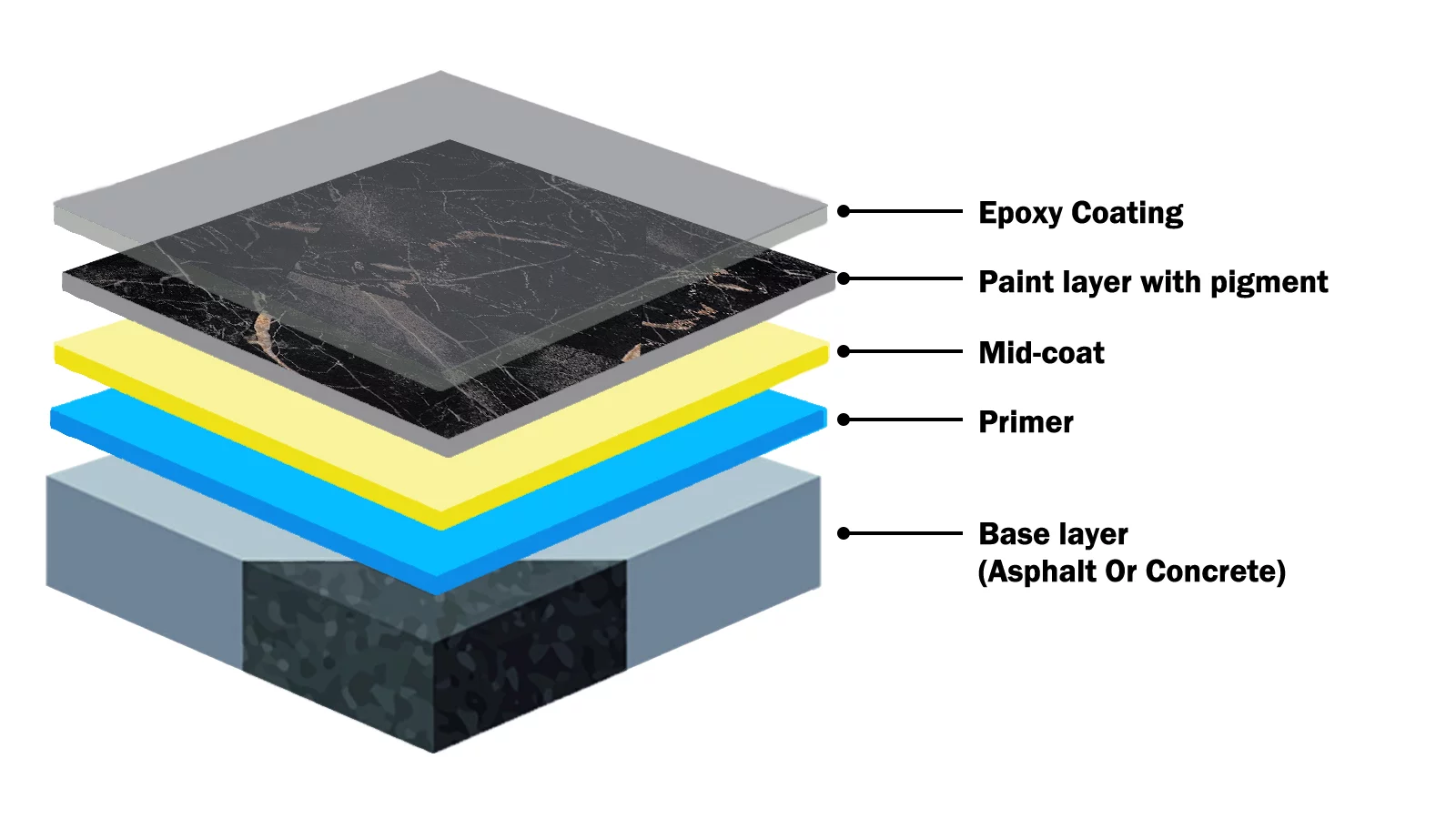

Description:Our epoxy flooring system consists of a moisture barrier coating (protecting your investment from moisture intrusion), a solid epoxy coating containing metallic pigments, and a topcoat, creating a marble-like or cloud-like decorative finish. Combining aesthetics, durability, and low maintenance, it represents a cost-effective investment for any property owner.

Durability: Our metallic epoxy flooring is exceptionally durable, withstanding heavy foot traffic, mechanical impact, and liquid spills. Additionally, it resists chemicals, stains, and scratches, making it an ideal choice for industrial and commercial spaces.

Aesthetics: Metallic epoxy flooring offers stunning visual appeal, adding a touch of elegance and sophistication to any space. With a wide range of colors and patterns available, you have the flexibility to create unique, personalized designs.

Low Maintenance: Metallic epoxy flooring is easy to clean and requires minimal upkeep. Simply sweep, mop, or use mild cleaners to keep it looking its best.

Cost-Effective and Long-Lasting: Metallic epoxy flooring boasts a long lifespan, lasting for years. Compared to alternatives like hardwood, tile, or carpet, they represent a cost-effective solution. Their durability and low maintenance requirements translate to long-term savings.

Enhances Property Value: Metallic epoxy flooring increases your property’s market appeal. For many buyers, it’s a desirable feature that can help you sell faster and at a higher price.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=3:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

| Available Time | 0.5H (10℃) | 0.4H(25℃) | 0.25H(30℃) | |

| VOC | ≤2%(After mixing) | |||

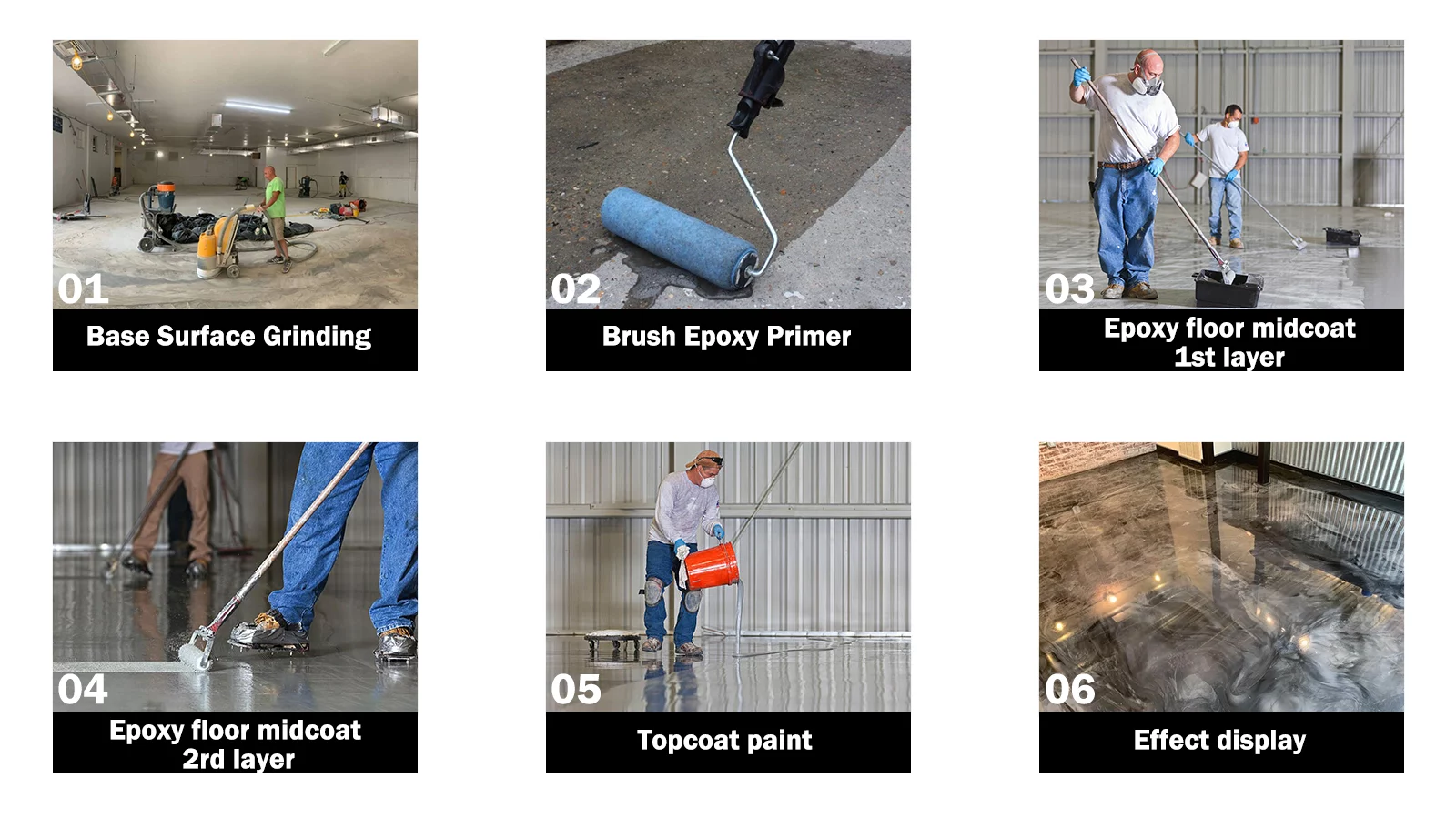

1. Substrate Preparation: Thoroughly grind and clean the base layer to ensure the surface is solid, level, and free of oil contamination, providing a solid foundation for subsequent coatings.

2. Epoxy Primer Application: Roll on a specialized epoxy primer to fully penetrate and seal the substrate, serving as a critical reinforcing layer that bridges the base and topcoats.

3. Epoxy Intermediate Coat Application: Apply epoxy intermediate coating by trowel, evenly distribute metallic powder or lay metallic flakes to create a distinctive metallic texture and visual effect.

4. Fine Grinding and Finishing: After the intermediate coat cures, finely grind the surface to remove excess metallic material, achieving a smooth finish that reveals uniform metallic texture.

5. Apply transparent topcoat: Roll or trowel high-performance transparent polyurethane or epoxy topcoat across the entire surface to protect the metallic layer and enhance the floor’s abrasion resistance, scratch resistance, and chemical resistance.

6. Seal and cure: After completion, seal off the site and allow sufficient time for the coating to fully cure. The floor may only be put into use once optimal physical properties are achieved.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000