Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Microelectronics manufacturing facilities, pharmaceutical sterile production areas, food processing plants, automotive manufacturing plants, hotel lobbies, luxury flagship stores, convention centers, airport terminals, large shopping malls, underground parking garages, subway stations, hospital operating rooms, laboratories, school libraries, high-speed rail platforms, biological laboratories, chip packaging workshops, art museum exhibition halls.

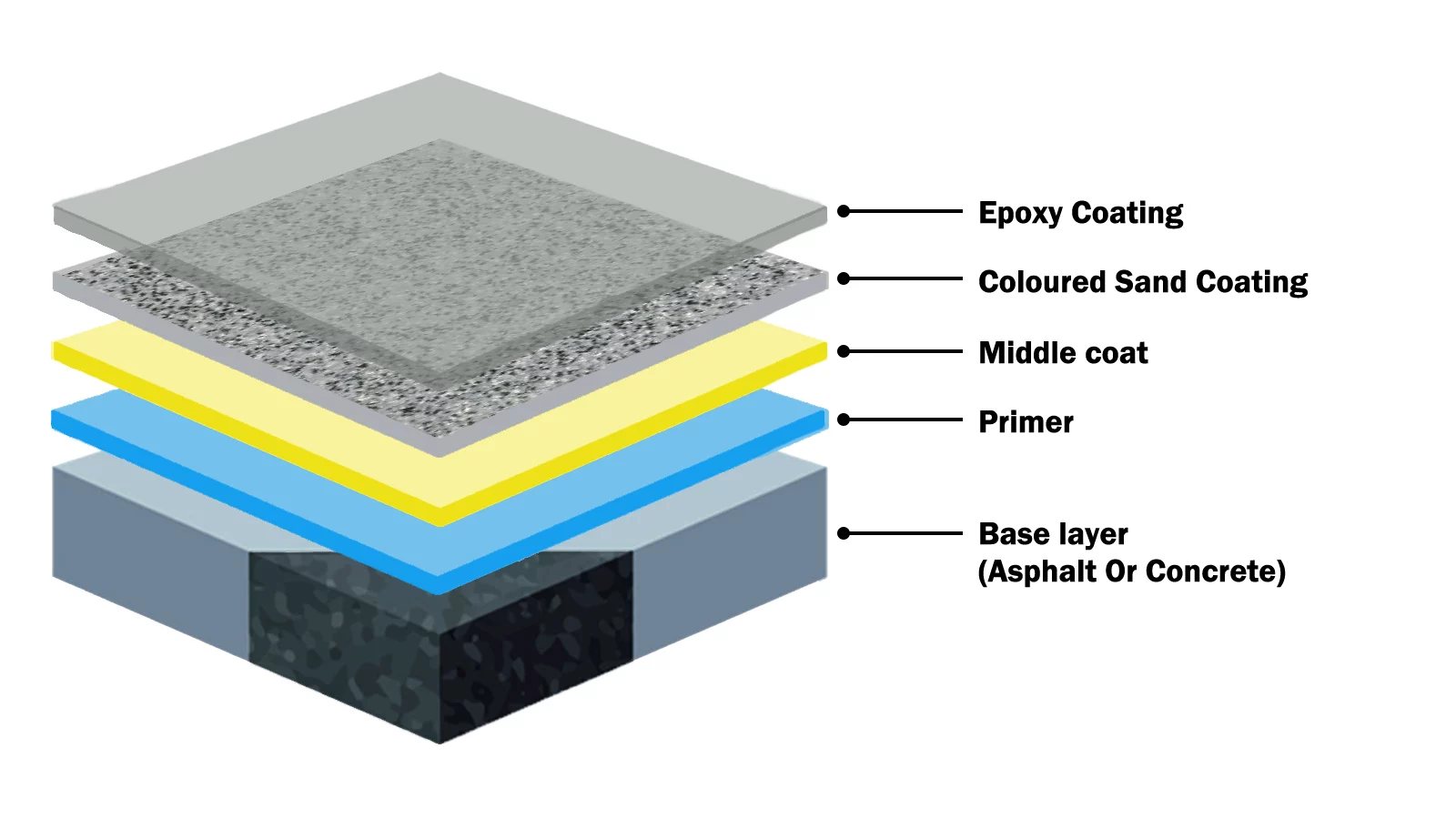

Description:Self-leveling colored sand epoxy flooring utilizes solvent-free epoxy resin as the bonding base material, blended with multi-graded quartz colored sand (particle size gradient 0.1-1.2mm) and nano-interface enhancers to form a composite system with self-leveling properties. This system breaks through the traditional simple mixing approach of colored sand and resin, achieving uniform dispersion and stable bonding of suspended colored sand particles.

Epoxy colored sand flooring is a seamless, high-end flooring system composed of colored quartz sand blended with high-performance epoxy resin. Through the artful blending of differently colored sand particles, it creates vibrant, textured surfaces with exceptional decorative appeal. Not only aesthetically pleasing and wear-resistant, it also offers outstanding compression strength, slip resistance, chemical corrosion resistance, and easy maintenance. Perfectly merging artistic beauty with practical functionality, it is widely used in commercial centers, exhibition halls, transportation hubs, hospitals, and high-end industrial facilities, showcasing unique taste and style.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=3:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

| Available Time | 0.5H (10℃) | 0.4H(25℃) | 0.25H(30℃) | |

| VOC | ≤2%(After mixing) | |||

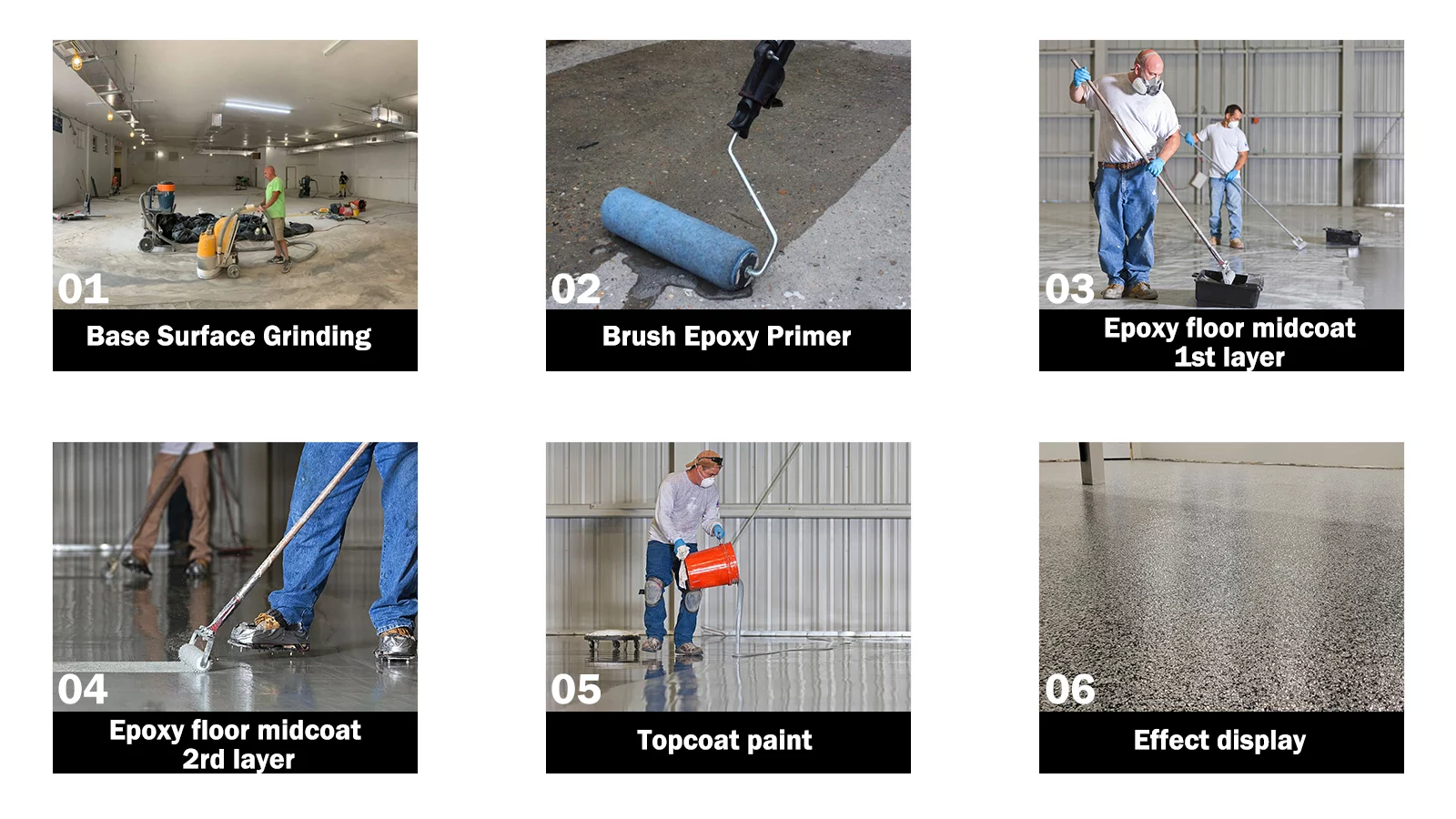

1. Substrate Preparation: Mechanically rough-grind the substrate to achieve a level surface. Remove laitance, oil stains, loose particles, and repair cracks and pits. Ensure the surface is dry and free of hollow areas.

2. Epoxy Primer: Apply using roller or trowel techniques to enhance substrate adhesion and sealing properties, providing a solid bonding foundation for subsequent coatings.

3. Epoxy Intermediate Coat: Applied by troweling or scraping to enhance abrasion and impact resistance, fill substrate imperfections, and improve surface levelness.

4. Fine Grinding and Dust Removal: Mechanically grind the intermediate coat to remove loose particles, residual debris, and eliminate scratches or unevenness, enhancing overall floor flatness.

5. Epoxy Putty: Applied by troweling to achieve precise leveling of the intermediate coat, effectively eliminating microscopic surface irregularities and sealing fine pores;

6. Colored Sand Topcoat: Applied by troweling to form a dense protective layer with a three-dimensional cross-linked structure, ensuring the physical and chemical properties of the material system.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000