Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Suitable for environments requiring electrostatic discharge (ESD) protection, including electronics, telecommunications, printing plants, server rooms, precision machinery factories, powder processing, chemical plants, defense industries, aerospace, and ESD-sensitive areas.

Description:

1. Rapidly dissipates static electricity to prevent damage to electronic components and fires caused by static buildup

2. Surface resistance remains stable and durable, unaffected by humidity or surface wear

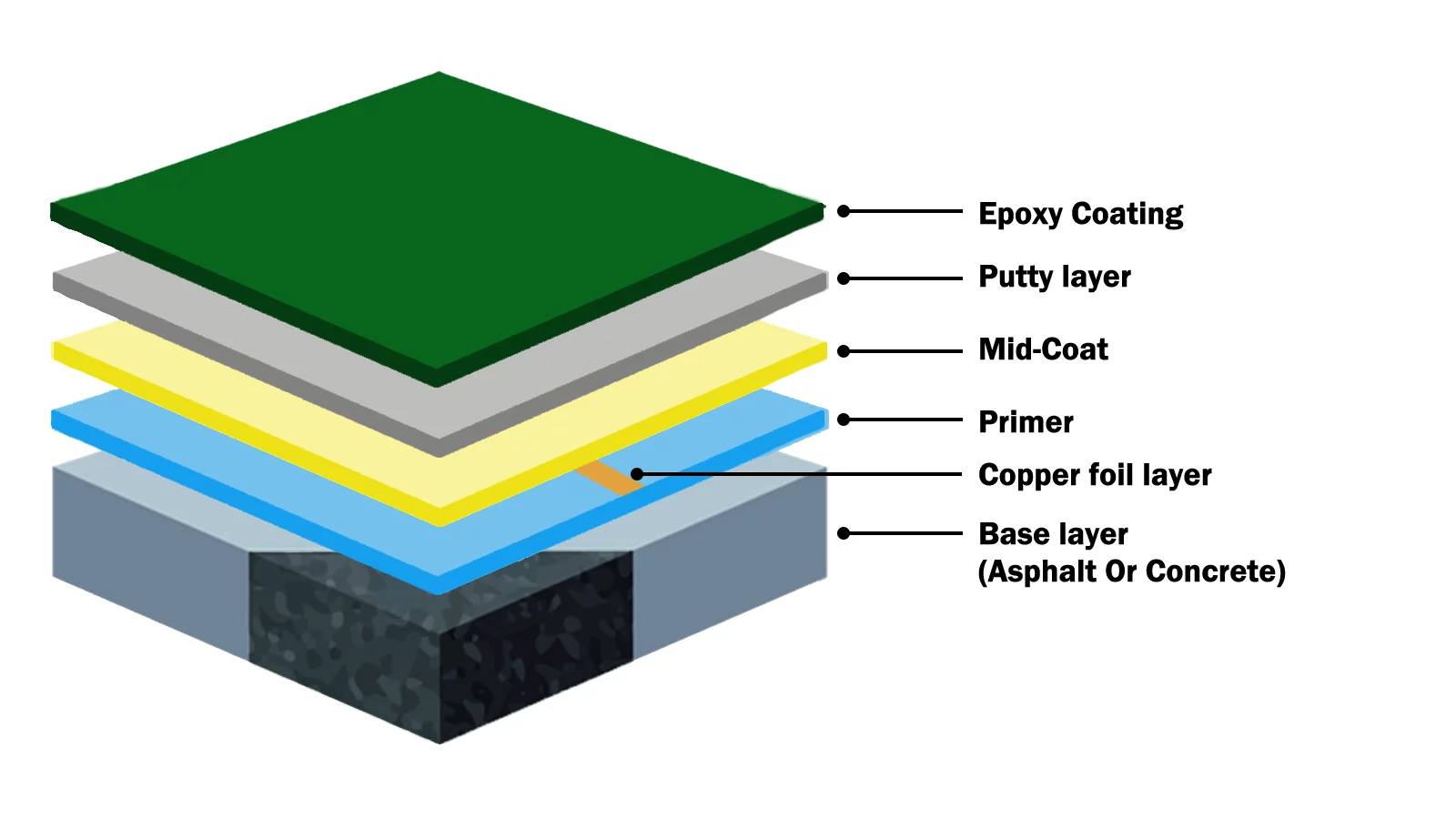

Epoxy anti-static self-leveling flooring is a high-performance flooring system specifically designed for static-sensitive environments. By incorporating conductive copper foil and special conductive materials, it forms a stable charge dissipation layer that rapidly and effectively eliminates static buildup during production, preventing electrostatic discharge (ESD) damage. Combining the exceptional properties of epoxy self-leveling flooring—ultimate flatness, seamless cleanliness, and resistance to wear and chemical corrosion—it is the ideal choice for industries demanding high anti-static and clean environments, including electronics, semiconductors, precision instruments, aerospace, pharmaceuticals, and defense.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=4:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

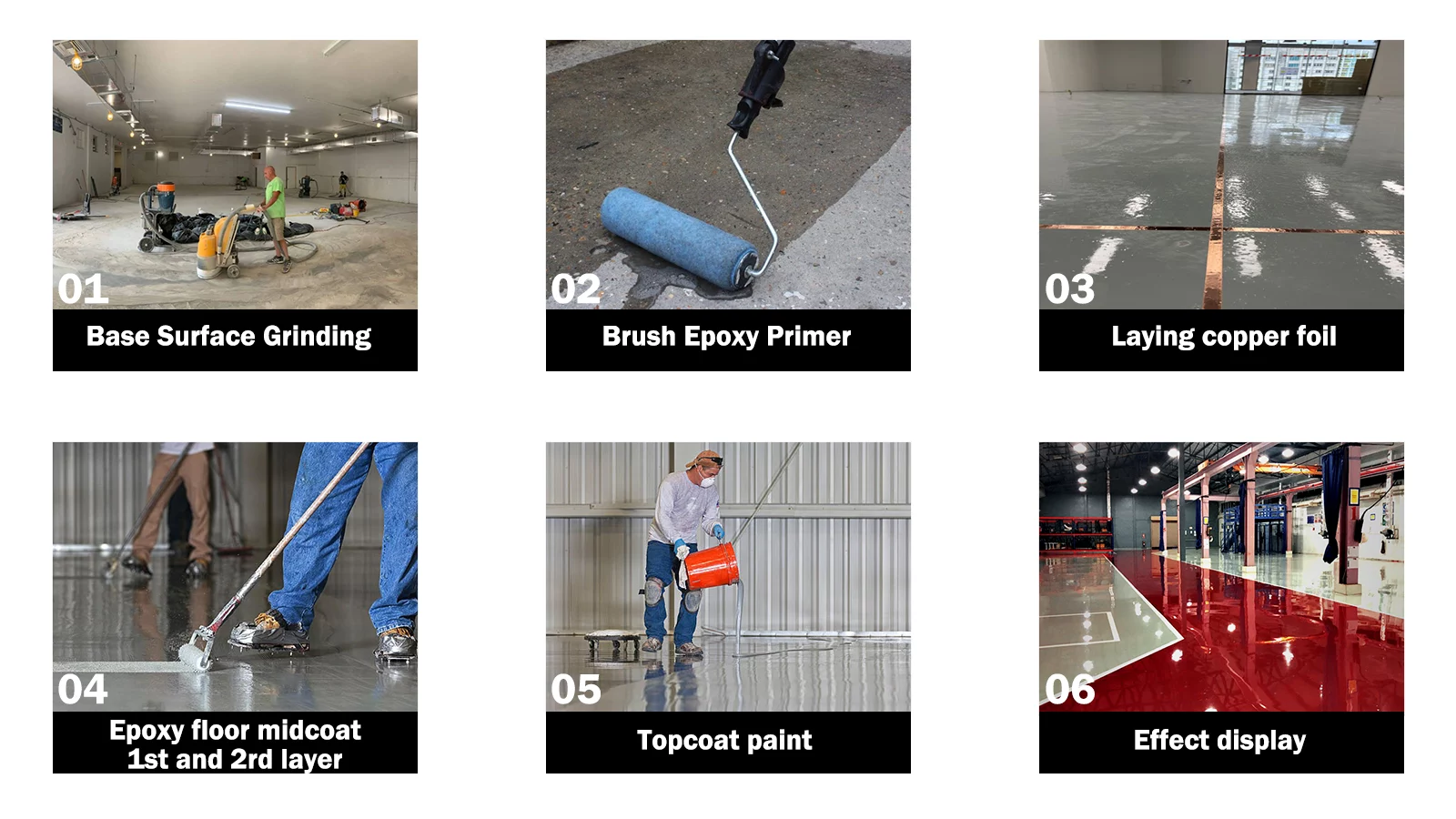

1. Substrate Preparation: Mechanically rough-grind the substrate to achieve a level surface. Remove loose particles, oil stains, and floating mortar. Repair cracks and pits to ensure the surface is dry and free of hollow areas.

2. Anti-static Primer: Apply via roller or trowel to enhance substrate adhesion and sealing, providing a robust bonding foundation for subsequent coatings;

3. Copper Foil Installation: Lay conductive copper foil in a grid pattern with horizontal and vertical spacing ≤3m (increase to 2m×2m in high-risk areas);

4. Anti-static intermediate coat: Applied by trowel or squeegee to enhance wear and impact resistance, fill substrate defects, and improve surface levelness;

5. Fine grinding and dust removal: Mechanically grind the intermediate coat to eliminate loose particles, sand residue, and imperfections, while smoothing scratches and unevenness to enhance floor flatness;

6. Anti-static skim coat: Applied by troweling to achieve precise leveling of the intermediate coat, effectively eliminating microscopic surface irregularities and sealing fine pores;

7. Self-leveling anti-static topcoat: Applied by troweling to form a dense protective layer with a three-dimensional cross-linked structure, ensuring the physical and chemical properties of the material system.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000