Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Anti-corrosion flooring for electroplating, chemical, food, pharmaceutical, printing and dyeing, hardware, and machinery factories, along with wastewater treatment. (Mechanical manufacturing plants and hardware factories require flooring with enhanced impact and tensile resistance. Electroplating plants and chemical industries demand flooring with specialised anti-corrosion properties, such as acid and alkali resistance for tanks and storage vessels. Roofs and floor slabs require protection against cracking.)

Description:

1. Resistant to corrosion from acids, alkalis, salts and other chemical substances.

2. Impact-resistant, capable of bearing heavy loads, with excellent tensile strength and outstanding structural integrity.

3. Aesthetically pleasing and durable, offering protection against dust, cracking and water leakage.

Epoxy anti-corrosion self-levelling flooring is a high-protection flooring system specifically engineered for extreme chemical environments. Utilising modified epoxy resin and specialised curing agents, it forms an exceptionally dense, seamless, and smooth surface capable of enduring prolonged exposure to high-concentration acids, alkalis, salts, solvents, and other chemicals without corrosion, permeation, or degradation. Its superior self-levelling properties ensure absolute floor flatness and eliminate dead corners, combining outstanding mechanical performance with ease of cleaning. This makes it the ideal choice for core facilities in pharmaceuticals, chemical processing, electroplating, battery manufacturing, laboratories, and other environments demanding stringent corrosion resistance and cleanliness standards.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.2±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=2:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

| Available Time | 0.5H (10℃) | 0.3H(25℃) | 0.2H(30℃) | |

| VOC | ≤1%(After mixing) | |||

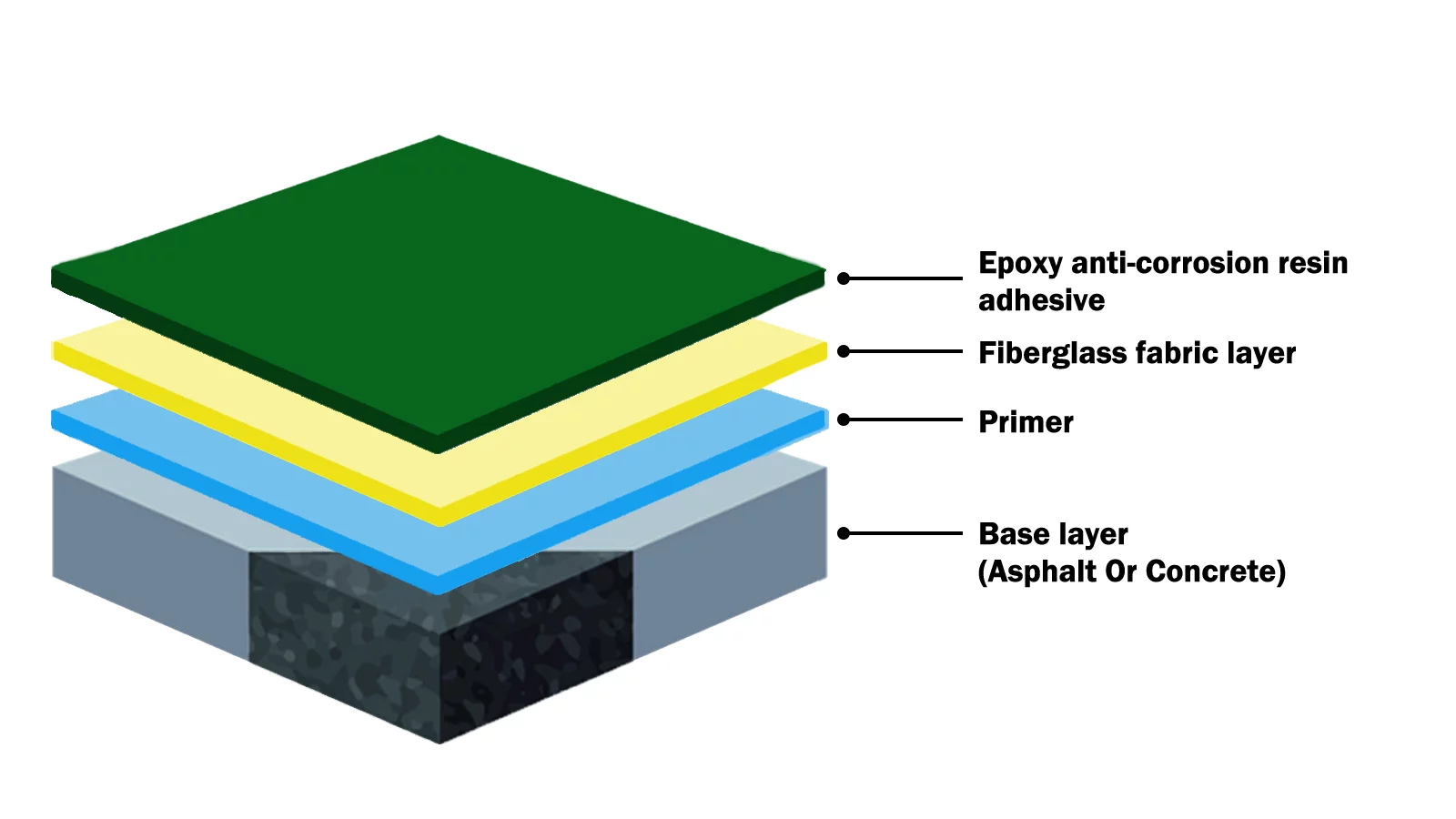

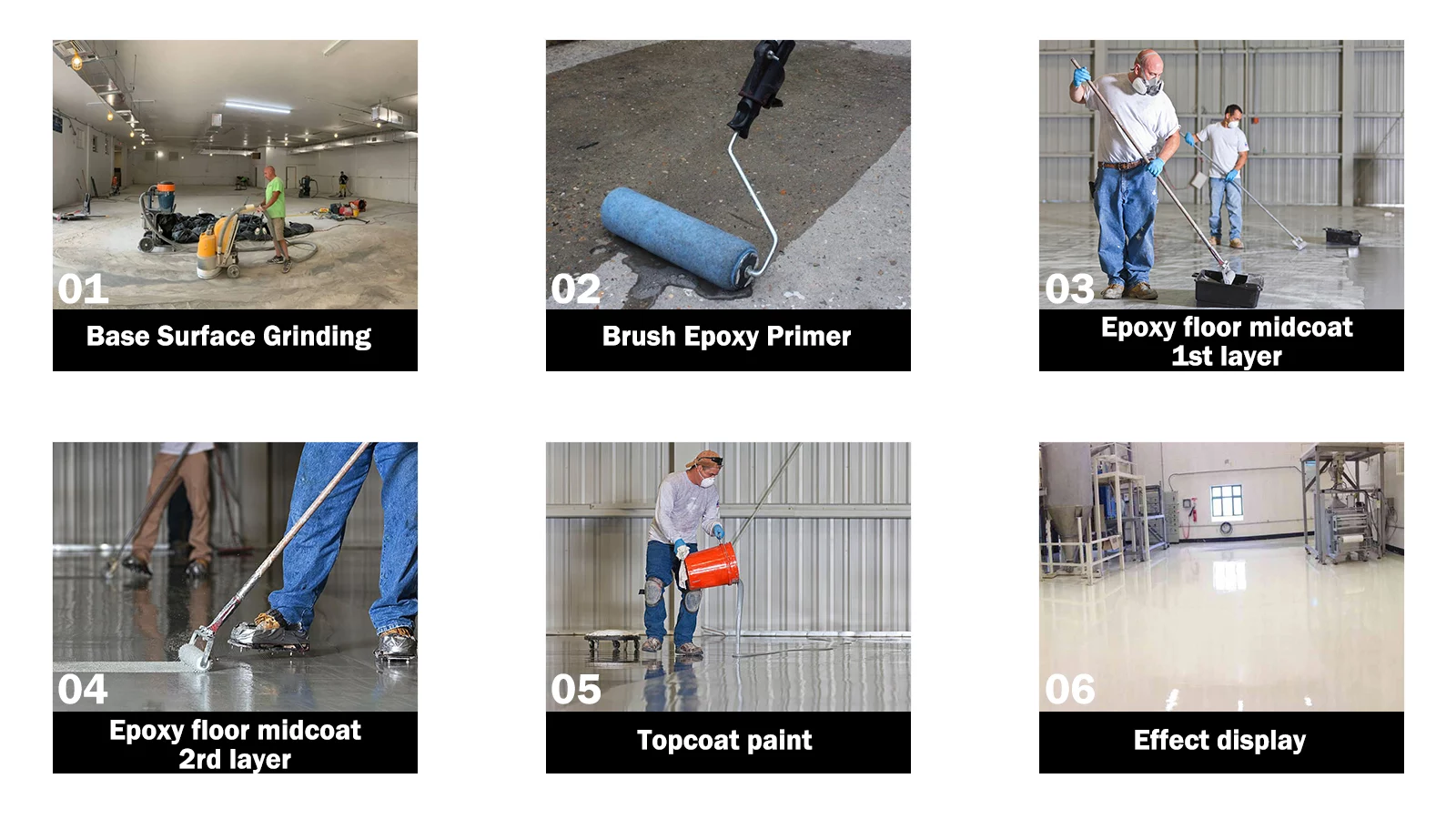

1. High-standard substrate preparation: Thoroughly mill, sandblast or finely grind the concrete substrate to fully expose the sound base layer. All oil residues and contaminants must be removed, ensuring the substrate achieves the specified roughness and flatness required to guarantee coating adhesion and corrosion protection.

2. Application of Epoxy Anti-Corrosion Primer: Apply one coat of specialised epoxy anti-corrosion primer using roller or trowel application. This primer effectively penetrates the substrate, serving a crucial role in reinforcement, sealing, and bonding, while providing initial corrosion resistance.

3. Laying Anti-Corrosion Fibreglass Cloth (Reinforced Type): Apply one or multiple layers of fibreglass cloth onto the uncured intermediate coat, thoroughly saturating it with epoxy anti-corrosion coating. This step significantly enhances the floor’s integrity, tensile strength, and crack resistance, being crucial for improving corrosion durability.

4. Trowelling the Epoxy Anti-Corrosion Mortar Layer: Mix the epoxy anti-corrosion intermediate coating material with quartz sand of specified grain size, then apply evenly by trowel. This mortar layer effectively levels the surface, forming a robust base layer with high thickness, compressive strength, and impact resistance, providing the primary structural foundation for core corrosion protection.

5. Trowelling the Epoxy Anti-Corrosion Topcoat: Apply the prepared epoxy anti-corrosion topcoat evenly using a trowel. The topcoat provides the floor’s final dense anti-corrosion layer, directly resisting chemical medium erosion while forming a seamless, smooth, and easy-to-clean surface.

6. Thorough curing and solidification: After completion, strictly adhere to material requirements for adequate curing time. Allow the coating to fully cross-link and solidify, achieving optimal chemical stability and physical properties before use. During this period, the site must be strictly sealed off with controlled temperature and humidity.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000