Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Suitable for all types of manufacturing workshops, warehouses and logistics centres, assembly and maintenance facilities, food and pharmaceutical factories, car parks, freight stations and docks, backstage areas of large venues, cold chain logistics, schools and hospitals.

Description:Diamond abrasive wear-resistant flooring (also known as wear-resistant flooring) is a high-strength, abrasion-resistant surface system. It utilises metallic or non-metallic wear-resistant aggregates as its core material, applied concurrently with the cement-based concrete substrate. The system is mechanically ground and finished to achieve a durable surface. Its fundamental principle involves the physical bonding of aggregates with concrete, forming an integral, dense wear-resistant layer that replaces traditional cement mortar levelling compounds.

Diamond-hardened wear-resistant flooring is a high-strength surface created by uniformly spreading diamond-hardened aggregate and grinding it into the concrete during its initial setting phase. The aggregate bonds permanently with the concrete substrate, forming an exceptionally durable surface that offers outstanding wear resistance, impact resistance, and dust and sand prevention. Economical and long-lasting, it requires no additional coatings and boasts an extremely long service life. It is widely applicable in industrial workshops, warehouses, logistics centres, car parks, and other locations demanding the highest levels of wear resistance.

| Classification | Parameter | Test Standard |

| Mohs Hardness | ≥7.5; or Indentation Diameter ≤3.1mm (metallic aggregate) | ASTM C1327-15 |

| Dust Resistance | Surface free of visible dust, Dust Release ≤0.02g/m² | JGJ/T 331-2014 |

| Dust Release | Weight loss ≤0.02g (non-metallic aggregate, 1000r/500g) | GB/T 16925-1997 |

| Impact Resistance | 2250g steel ball dropped from 1m height, dent diameter ≤12mm, depth ≤0.3mm | GB/T 1732-2020 |

| Compressive Strength | 28 days ≥80MPa (metallic aggregate); ≥70MPa (non-metallic aggregate) | GB/T50081-2019 |

| Flexural Strength | 28 days ≥13.5MPa (metallic aggregate); ≥11.5MPa (non-metallic aggregate) | GB/T50081-2019 |

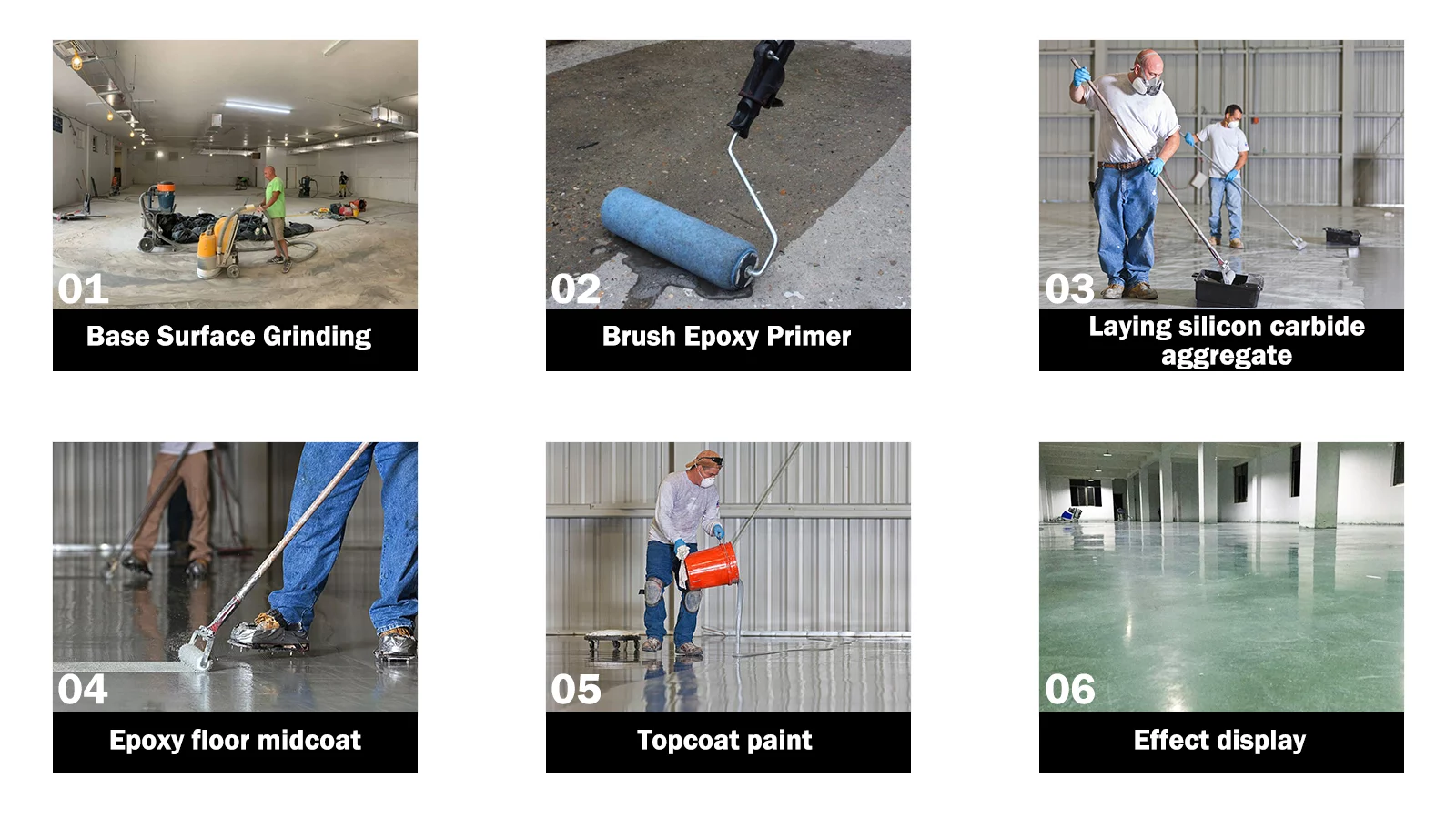

1. Substrate Preparation: Remove debris, loose particles, hollow areas and oil-stained sections before grinding. Roughen smooth surfaces and establish concrete elevation benchmarks.

2. Concrete Placement: Use concrete with strength grade ≥ C25 and slump controlled at 120–140mm. Level using laser screed or screed bar before initial setting, achieving ≤3mm deviation when tested with 2m straightedge.

3. Concrete Bleeding: When concrete compresses under foot by approximately 5mm or 3-4 hours post-pouring, employ a disc trowel to draw out bleed water and eliminate segregation;

4. Abrasive Application: Apply 2/3 of total abrasive aggregate evenly in the first pass. Roughly level with a wooden float to ensure aggregate-concrete bonding. For the second application, scatter the remaining one-third of aggregate vertically. Manually supplement corners and adjust local flatness.

5. Compaction and finishing: After aggregate application, use a disc-equipped trowel machine to grind the surface twice in both directions, eliminating segregation and compacting the aggregate. Before final setting, switch to metal blades and adjust speed and angle to complete 3-4 passes of fine grinding and polishing. Finish corners manually with an iron trowel.

6. Cutting and Curing: Determine cutting timing based on ambient temperature (typically within 24 hours). Within 4-6 hours post-construction, spray specialised oil-based curing compound or cover with damp geotextile, maintaining moisture for 7 days.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000