Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Suitable for heavy industrial buildings, logistics warehouses, underground car parks, large supermarket retail spaces, food and pharmaceutical production facilities, and refurbishment of existing flooring.

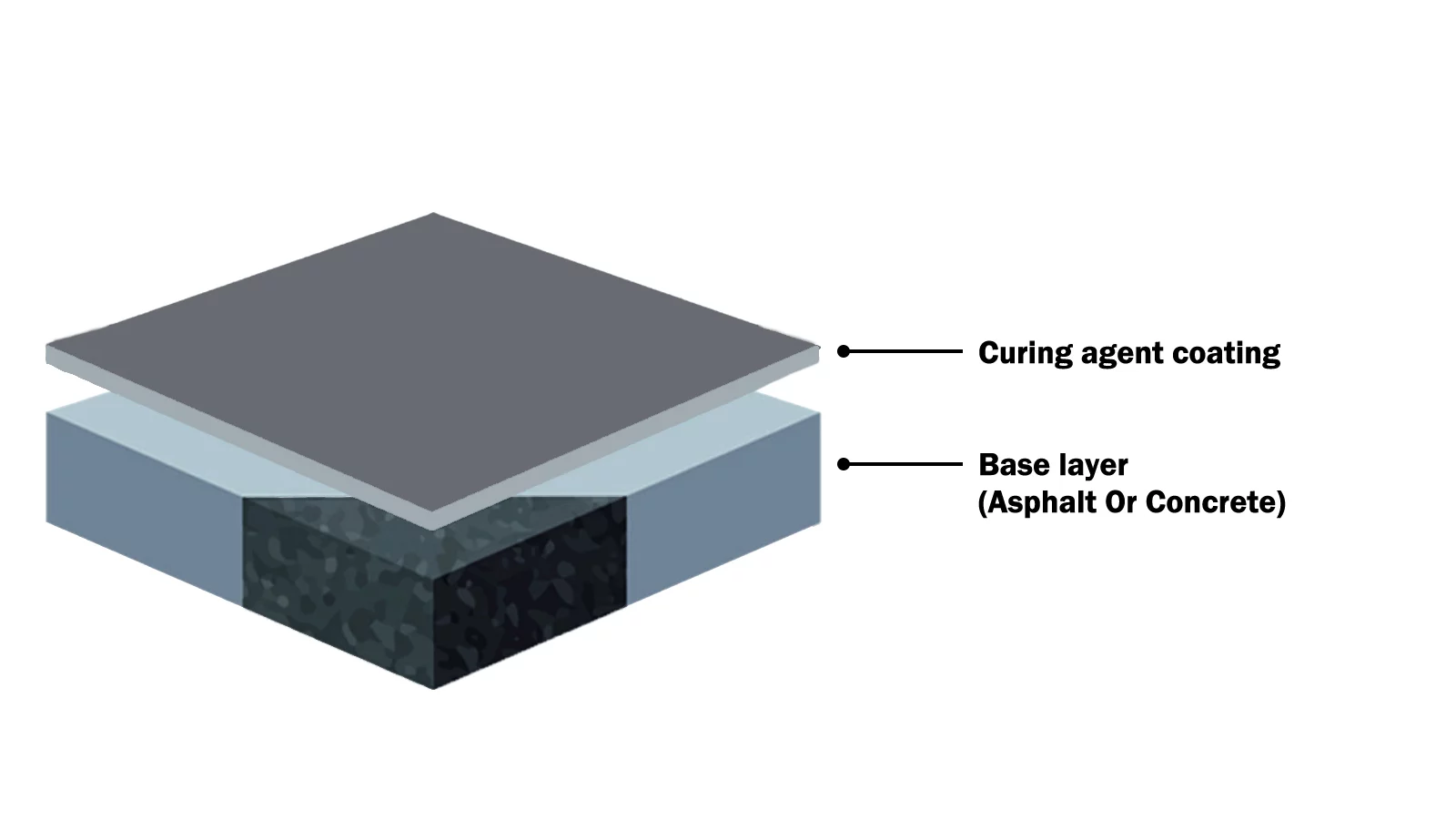

Description:Concrete hardener flooring systems achieve permanent enhancement of surface hardness, density and abrasion resistance through chemical reactions between permeable liquid hardeners and the concrete substrate.

Concrete curing agent flooring systems achieve permanent enhancement of surface hardness, density and abrasion resistance through chemical reactions between permeable liquid curing agents and concrete. Characterised by dust-free properties, wear resistance, impermeability and ease of cleaning, these systems require no coating maintenance and boast exceptionally long service lives. They represent an ideal, cost-effective solution for industrial warehouses, logistics centres, car parks and other applications demanding high floor strength.

| Classification | Parameter | Test Standard |

| Mohs hardness | Grade 3-4 | Industry-wide testing method |

| Abrasion resistance | Moderate, with some wear rate | GB/T 1768 |

| Compressive strength | Based on design strength grades such as C20, C30, etc. C20 concrete exhibits a 28-day compressive strength ≥20MPa, while C30 concrete achieves ≥30MPa | GB/T 50081 |

| Impermeability | Generally lower impermeability grade; meets standard waterproofing requirements unless otherwise specified | GB 50164 |

| Slip resistance | Dry surface slip resistance coefficient ≥0.5, wet state ≥0.4, moderate surface roughness | JT/T 733 |

| Dust resistance | Moderate, may exhibit slight dusting | GB 50209-2010 |

1. Substrate cleaning and grinding: Thoroughly clean the floor surface, using a grinder to remove laitance and open the pores.

2. Spraying the curing agent: Apply the material evenly across the floor, ensuring full saturation.

3. Penetration reaction: Allow the material to react fully with the concrete for approximately 2-4 hours.

4. Grinding and cleaning: Re-grind to promote further material penetration and clean the surface.

5. Initial polishing: Perform multiple cross-polishing passes using resin grinding discs.

6. Fine polishing: Achieve a marble-like lustre through final high-speed polishing.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000