Personalizado según la zona del emplazamiento

Cantidad mínima de pedido: 500 metros cuadrados

Escenarios de aplicación: Plantas farmacéuticas GMP, hospitales, instalaciones de hemoderivados y otras salas blancas; plantas de fabricación de maquinaria de precisión y microelectrónica; áreas con elevados requisitos de rendimiento mecánico y químico.

Descripción:

1. 2. Resistente al desgaste, resistente a la presión, resistente a los impactos, resistente al calor, impermeable y con cierto grado de elasticidad;

2. La capa superficial de revestimiento epoxi para suelos se aplica en un proceso de una sola pasada, lo que garantiza una instalación rápida y cómoda.

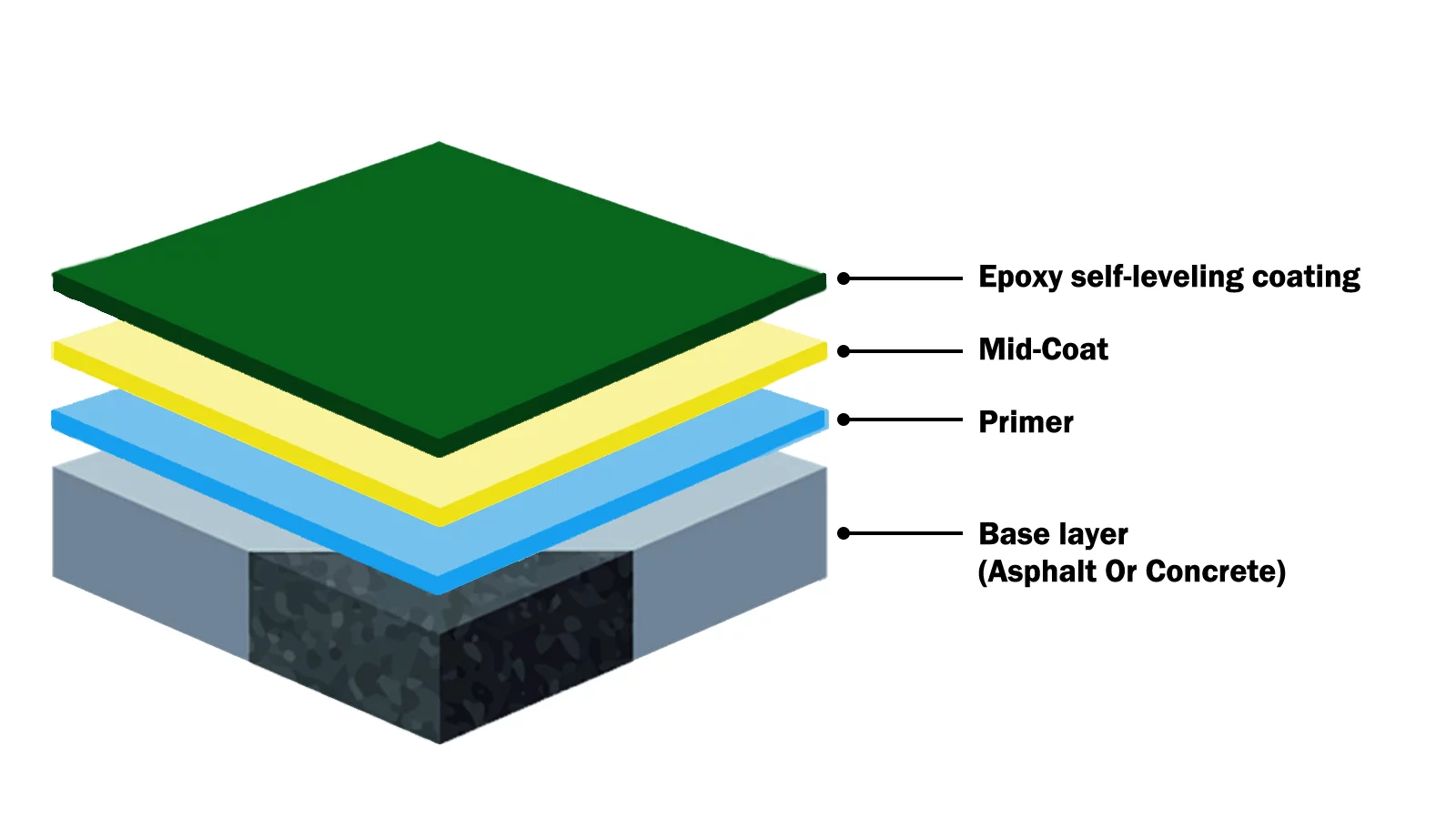

Los suelos autonivelantes epoxídicos constituyen un sistema de suelos industriales de primera calidad. Este revestimiento líquido depende de su propio peso y de sus propiedades de alta fluidez para autonivelarse, formando un acabado excepcionalmente liso, sin juntas y con aspecto de espejo. No sólo ofrece una resistencia al desgaste, a la corrosión y a los impactos muy superior a la de los suelos con revestimiento estándar, sino que también cumple los estrictos requisitos de los entornos muy limpios, sin polvo y estériles. Se utiliza ampliamente en talleres de las industrias farmacéutica, electrónica, alimentaria, de fabricación de precisión y en espacios comerciales de alta gama.

| Proyecto | Componente A | Componente B | ||

| Color | Personalizable | Amarillo pálido o transparente | ||

| Proporción | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Componente A/Componente A=3:1 | |||

| Tiempo de curado | Superficie-Seca | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Peatón | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Carga pesada | 7 días(10℃) | 4 días(25℃) | 2 días(30℃) | |

| Tiempo disponible | 0.5H (10℃) | 0.4H(25℃) | 0.25H(30℃) | |

| COV | ≤2%(Después de mezclar) | |||

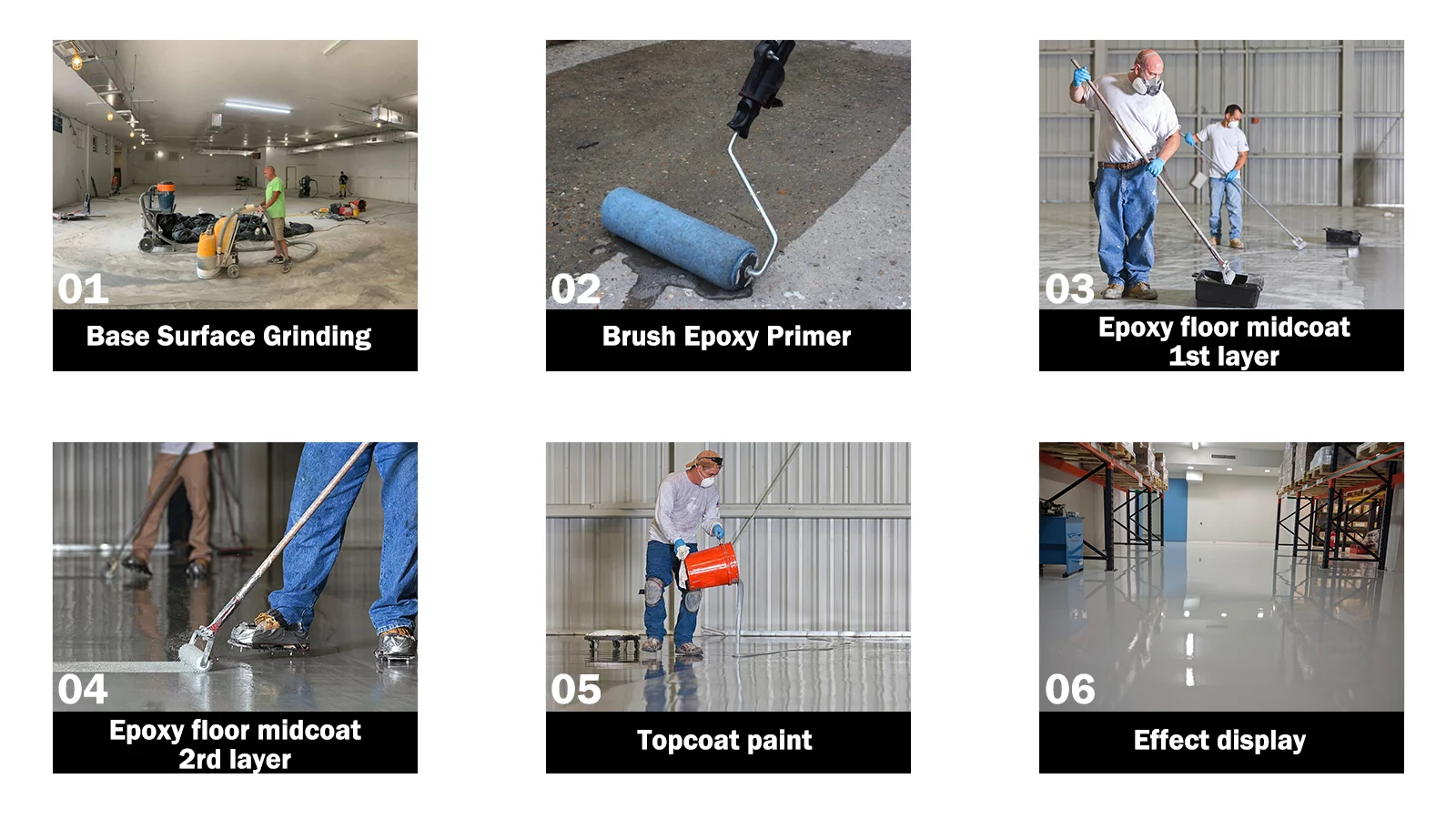

1. Preparación del sustrato: El sustrato de hormigón se somete a un esmerilado y limpieza meticulosos para eliminar a fondo la lechada y la contaminación por aceite. Las grietas y los agujeros se reparan para garantizar que la base sea robusta, nivelada y limpia, la base para lograr el acabado final.

2. Aplicación de imprimación: Una imprimación epoxídica de alto rendimiento se extiende sobre la superficie, permitiendo que penetre completamente en el sustrato. Esto desempeña un papel crucial a la hora de reforzar la base, sellar la superficie y adherir los revestimientos posteriores.

3. Aplicación de revestimiento autonivelante: Vierta el revestimiento autonivelante epoxi sin disolventes preparado sobre el suelo. Guíe el flujo utilizando una llana dentada especializada, permitiendo que la fluidez inherente del material cree una superficie excepcionalmente plana, lisa y sin juntas.

4. Curado: Tras la aplicación, deje que la superficie repose y se cure de forma natural. El área debe sellarse durante este período para evitar la interferencia de polvo y humedad hasta que el revestimiento alcance la resistencia suficiente para el tráfico peatonal y el uso.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegrama:+86 1375 1210 938

Telegrama:+86 1375 1210 938 Correo electrónico: ceo@dc-surface.com

Correo electrónico: ceo@dc-surface.com Dirección:No:332 Dalang Town Dongguan City China 523000

Dirección:No:332 Dalang Town Dongguan City China 523000