Personalizado según la zona del emplazamiento

Cantidad mínima de pedido: 500 metros cuadrados

Escenarios de aplicación: Fábricas de maquinaria, muebles, plásticos, etc.

Descripción: Resistente a la humedad, al polvo y al desgaste; instalación rápida, mantenimiento sencillo y bajo coste.

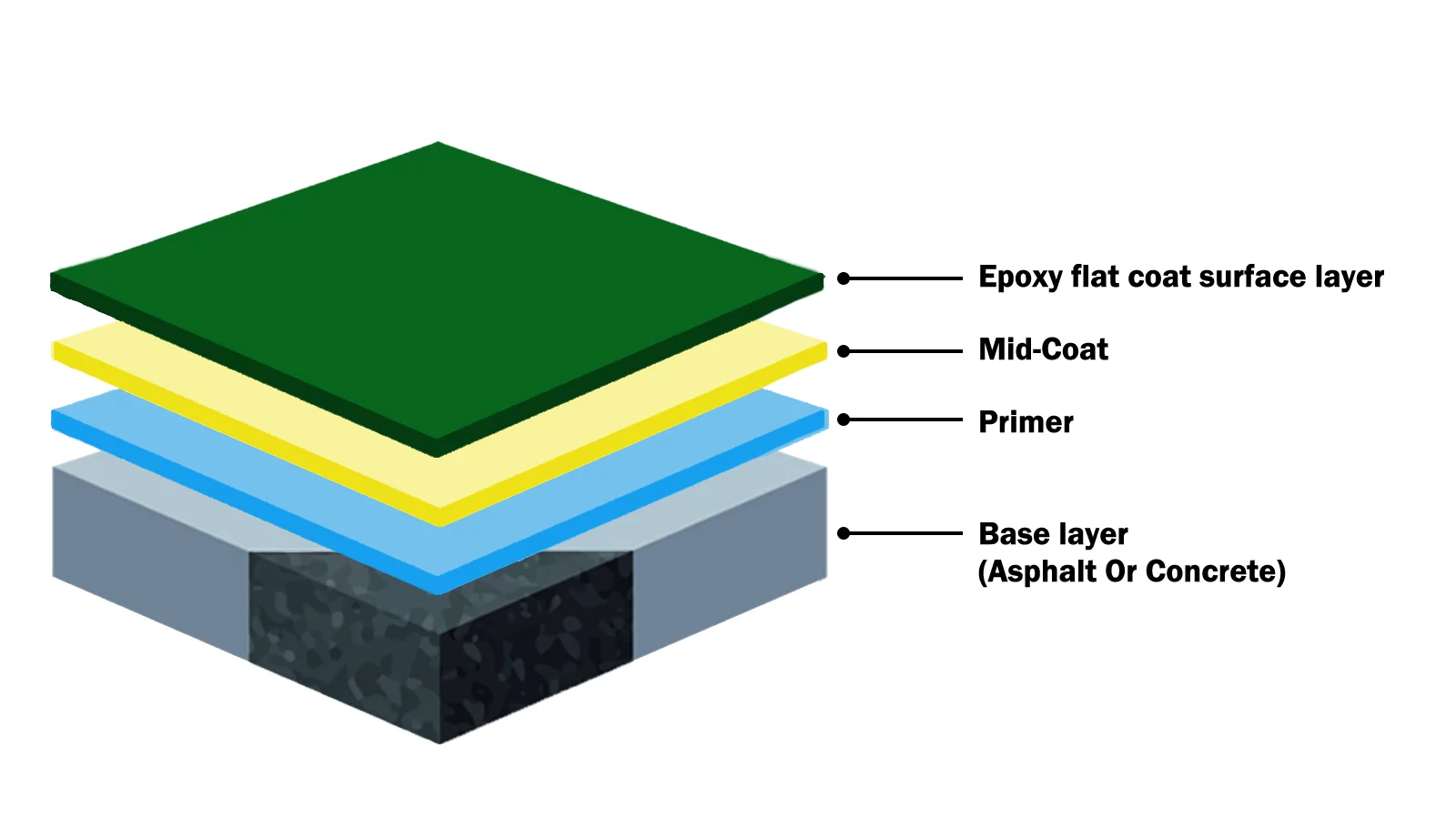

Los suelos autonivelantes epoxídicos ofrecen una solución económica y práctica para los suelos industriales. Su superficie sin juntas, lisa y brillante proporciona una excelente resistencia al desgaste, capacidad de carga, propiedades antipolvo y fácil mantenimiento. Ideal para entornos que exigen altos niveles de limpieza -como talleres de fábricas, garajes subterráneos, almacenes y espacios comerciales-, mejora eficazmente la estética ambiental y la experiencia del usuario. Con una instalación rápida y un mantenimiento sencillo, combina funcionalidad y atractivo visual.

| Proyecto | Componente A | Componente B | ||

| Color | Personalizable | Amarillo pálido o transparente | ||

| Proporción | 1.20±0.05 | 0..85~0.90 | ||

| Ratio | Componente A/Componente A=3:1 | |||

| Sólido | 98%以上 | |||

| Tiempo de curado | Superficie-Seca | 16H (10℃) | 10H(25℃) | 5H (30℃) |

| Peatón | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Carga pesada | 7 días(10℃) | 4 días(25℃) | 2 días(30℃) | |

| Tiempo disponible | 2.5H (10℃) | 30 Min(25℃) | 20 Min(30℃) | |

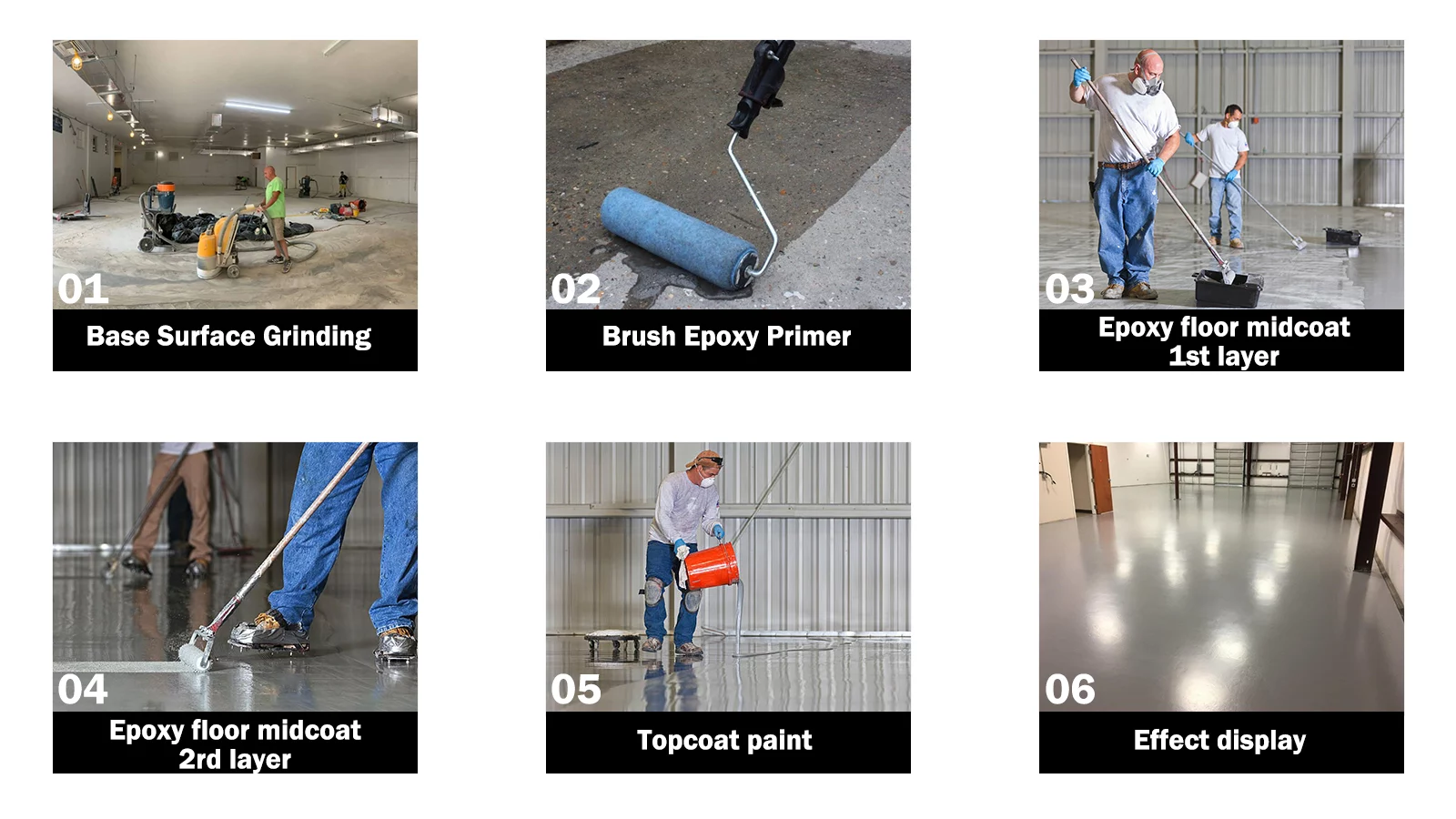

1.Preparación del sustrato y esmerilado: Limpie a fondo la superficie del suelo. Utilice esmeriladoras profesionales para esmerilar y granallar el sustrato, eliminando el mortero suelto, las manchas de aceite y las capas sueltas. Asegúrese de que el sustrato sea sólido, esté nivelado y limpio para proporcionar una adhesión excelente al revestimiento.

2.Aplicación de imprimación epoxi: Mezclar bien la imprimación epoxi sin disolventes según las proporciones especificadas y aplicar uniformemente con rodillo o llana. Esta capa penetra y refuerza el sustrato, sella la superficie y adhiere la capa base a los recubrimientos posteriores.

3.Alisado de la capa intermedia de mortero epoxi: Mezcle el revestimiento intermedio epoxi con la arena de cuarzo adecuada y, a continuación, aplíquelo con llana sobre la capa de imprimación curada. Este proceso nivela eficazmente el suelo, compensa las imperfecciones del sustrato y mejora significativamente la resistencia general a la compresión y a la abrasión del suelo.

4.Capa de masilla epoxi y aplicación de acabado: Aplique masilla epoxi para sellar y perfeccionar aún más la superficie. Por último, aplique uniformemente con rodillo la capa de acabado epoxi. La capa de acabado proporciona el acabado decorativo final (color, brillo) y ofrece excelentes propiedades de rendimiento, incluyendo resistencia a la abrasión, protección contra la corrosión y fácil limpieza.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegrama:+86 1375 1210 938

Telegrama:+86 1375 1210 938 Correo electrónico: ceo@dc-surface.com

Correo electrónico: ceo@dc-surface.com Dirección:No:332 Dalang Town Dongguan City China 523000

Dirección:No:332 Dalang Town Dongguan City China 523000