Personalizado según la zona del emplazamiento

Cantidad mínima de pedido: 500 metros cuadrados

Escenarios de aplicación:Adecuado para entornos que requieren protección contra descargas electrostáticas (ESD), como electrónica, telecomunicaciones, imprentas, salas de servidores, fábricas de maquinaria de precisión, procesamiento de polvos, plantas químicas, industrias de defensa, aeroespacial y áreas sensibles a ESD.

Descripción:

1. Disipa rápidamente la electricidad estática para evitar daños en los componentes electrónicos e incendios causados por la acumulación de electricidad estática.

2. La resistencia de la superficie permanece estable y duradera, sin verse afectada por la humedad o el desgaste de la superficie.

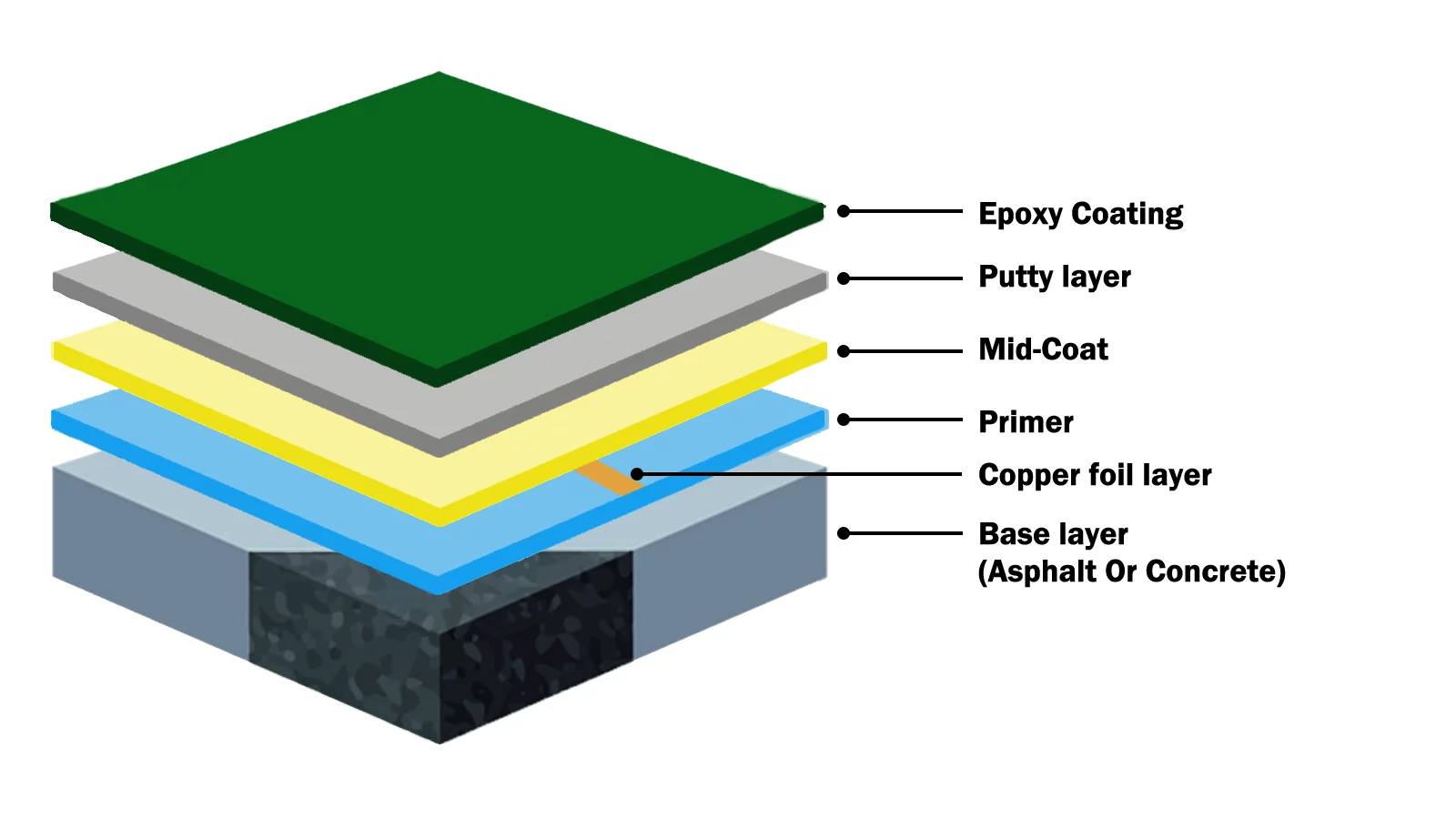

El pavimento autonivelante antiestático epoxi es un sistema de pavimentación de alto rendimiento diseñado específicamente para entornos sensibles a la estática. Al incorporar una lámina de cobre conductora y materiales conductores especiales, forma una capa de disipación de carga estable que elimina rápida y eficazmente la acumulación de estática durante la producción, evitando daños por descargas electrostáticas (ESD). Combinando las excepcionales propiedades de los suelos autonivelantes epoxídicos -última planitud, limpieza sin juntas y resistencia al desgaste y a la corrosión química- es la elección ideal para industrias que exigen entornos altamente antiestáticos y limpios, como la electrónica, los semiconductores, los instrumentos de precisión, la industria aeroespacial, la farmacéutica y la de defensa.

| Proyecto | Componente A | Componente B | ||

| Color | Personalizable | Amarillo pálido o transparente | ||

| Proporción | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Componente A/Componente A=4:1 | |||

| Tiempo de curado | Superficie-Seca | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Peatón | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Carga pesada | 7 días(10℃) | 4 días(25℃) | 2 días(30℃) | |

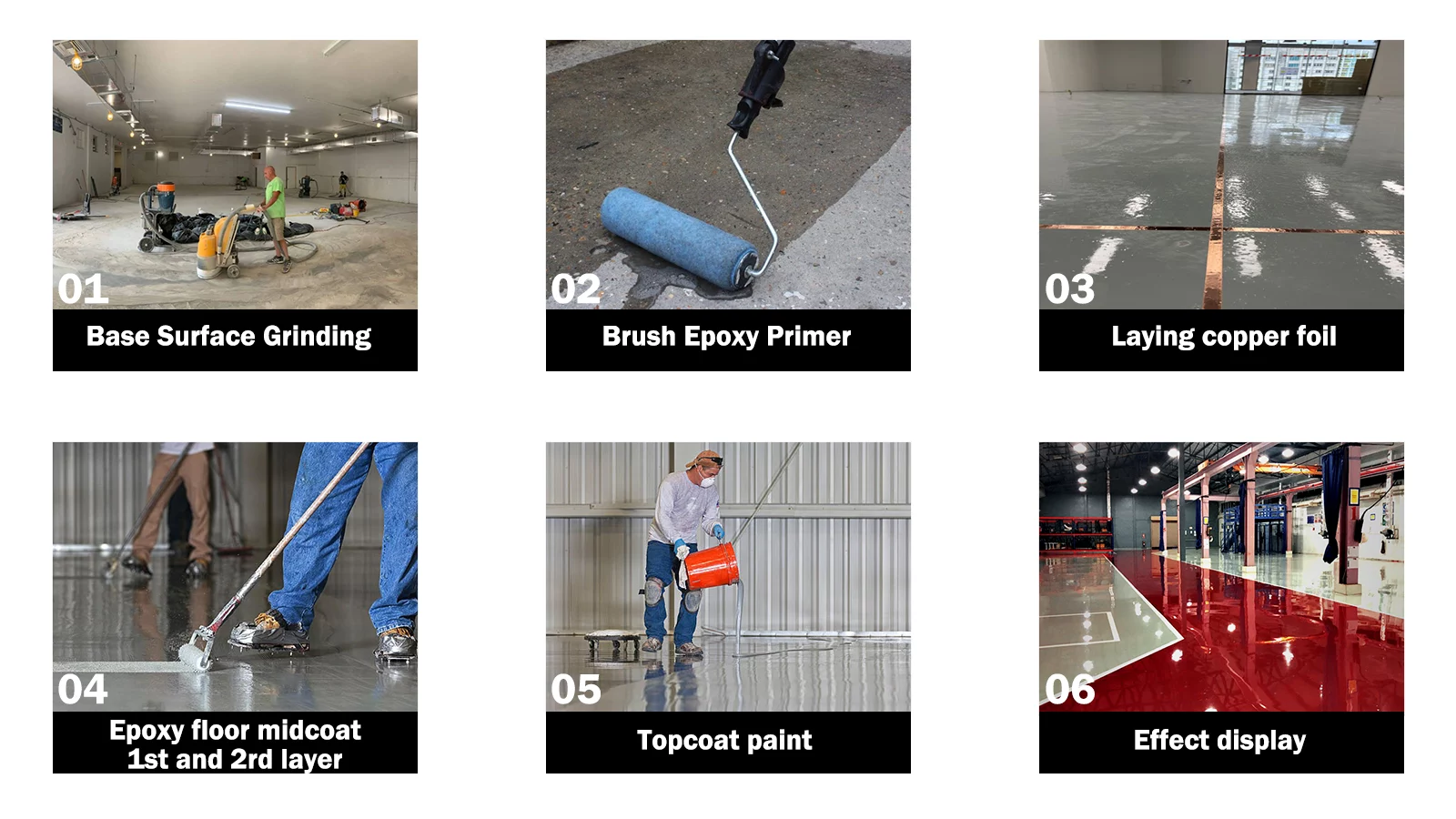

1. Preparación del sustrato: Desbastar mecánicamente el sustrato para conseguir una superficie nivelada. Eliminar las partículas sueltas, las manchas de aceite y el mortero flotante. Reparar grietas y hoyos para asegurar que la superficie esté seca y libre de zonas huecas.

2. Imprimación antiestática: Aplicar con rodillo o llana para mejorar la adherencia y el sellado del sustrato, proporcionando una sólida base de adherencia para los recubrimientos posteriores;

3. Instalación de láminas de cobre: Coloque láminas de cobre conductoras en forma de cuadrícula con una separación horizontal y vertical ≤3m (aumente a 2m×2m en zonas de alto riesgo);

4. Capa intermedia antiestática: Se aplica con llana o rasqueta para mejorar la resistencia al desgaste y a los impactos, rellenar los defectos del sustrato y mejorar la nivelación de la superficie;

5. Rectificado fino y eliminación de polvo: Lijar mecánicamente la capa intermedia para eliminar las partículas sueltas, los restos de arena y las imperfecciones, al tiempo que se alisan los arañazos y las irregularidades para mejorar la planitud del suelo;

6. Abrigo antiestático: Se aplica mediante fratasado para conseguir una nivelación precisa de la capa intermedia, eliminando eficazmente las irregularidades microscópicas de la superficie y sellando los poros finos;

7. Capa de acabado autonivelante antiestática: Se aplica mediante fratasado para formar una densa capa protectora con una estructura tridimensional reticulada, que garantiza las propiedades físicas y químicas del sistema material.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegrama:+86 1375 1210 938

Telegrama:+86 1375 1210 938 Correo electrónico: ceo@dc-surface.com

Correo electrónico: ceo@dc-surface.com Dirección:No:332 Dalang Town Dongguan City China 523000

Dirección:No:332 Dalang Town Dongguan City China 523000