Personalizado según la zona del emplazamiento

MOQ: 500 metros cuadrados

Aplicación: Ampliamente utilizado para canchas de baloncesto interiores y exteriores, pistas de tenis, pistas de bádminton, canchas de voleibol y mucho más. Su rendimiento constante en el rebote de la pelota, su excelente resistencia al deslizamiento y sus colores vivos y duraderos satisfacen las exigencias de las competiciones de alto nivel.

Descripción:El sistema de suelo acrílico elástico es un material para superficies deportivas versátil y de alto rendimiento. Gracias a su excepcional rendimiento atlético, su extraordinaria durabilidad y su rentabilidad, se ha convertido en la opción ideal para instalaciones deportivas profesionales y recreativas de todo tipo.

El suelo acrílico elástico equilibra a la perfección el rendimiento atlético profesional, la protección de la seguridad, la durabilidad a largo plazo y la rentabilidad, y constituye una solución integral para crear espacios deportivos modernos y de alta calidad. Tanto para instalaciones de competición profesional que buscan el máximo rendimiento atlético como para gimnasios públicos que dan prioridad a la seguridad y la salud, proporciona un apoyo sólido y fiable al suelo.

1.Sedes deportivas profesionales: Ampliamente utilizado en canchas de baloncesto cubiertas y al aire libre, pistas de tenis, pistas de bádminton, canchas de voleibol, etc. Su rendimiento estable en el rebote de la pelota, su excelente resistencia al deslizamiento y sus colores vivos y duraderos satisfacen las exigencias de las competiciones de alto nivel.

2.Espacios públicos de fitness: Una opción ideal para escuelas, gimnasios comunitarios y pabellones deportivos polivalentes. Sus superficies duraderas y resistentes al desgaste soportan un uso muy frecuente y la fricción de equipos pesados, al tiempo que son fáciles de limpiar y mantener con una larga vida útil.

3.Lugares de recreo: También se encuentran habitualmente en guarderías, centros de actividades infantiles y entornos similares. Su suave textura protege a los niños de golpes y magulladuras, mientras que sus vibrantes dibujos y colores estimulan la participación lúdica, creando un entorno animado y alegre.

| Indicador de resultados | Unidad | Valor estándar/Rango | Norma de ensayo |

| Espesor | mm | 3.0 – 5.0 | ASTM D813 |

| Dureza | Orilla A | 75 – 85 | ASTM D2240 |

| Absorción de impactos | % | 20 – 40 | ASTM F2772 |

| Deformación vertical | mm | 1.5 – 3.5 | ASTM F2772 |

| Rebote del balón | % | ≥ 90 | GB/T 14833 |

| Coeficiente de fricción por deslizamiento | – | 0.6 – 0.9 | ASTM E303 |

| Resistencia a la tracción | MPa | ≥ 1.8 | ASTM D2370 |

| Resistencia a la abrasión | g | ≤ 0.15 | ASTM D5963 |

| Resistencia a la intemperie | – | Sin ampollas, grietas ni caleo | ASTM G154 |

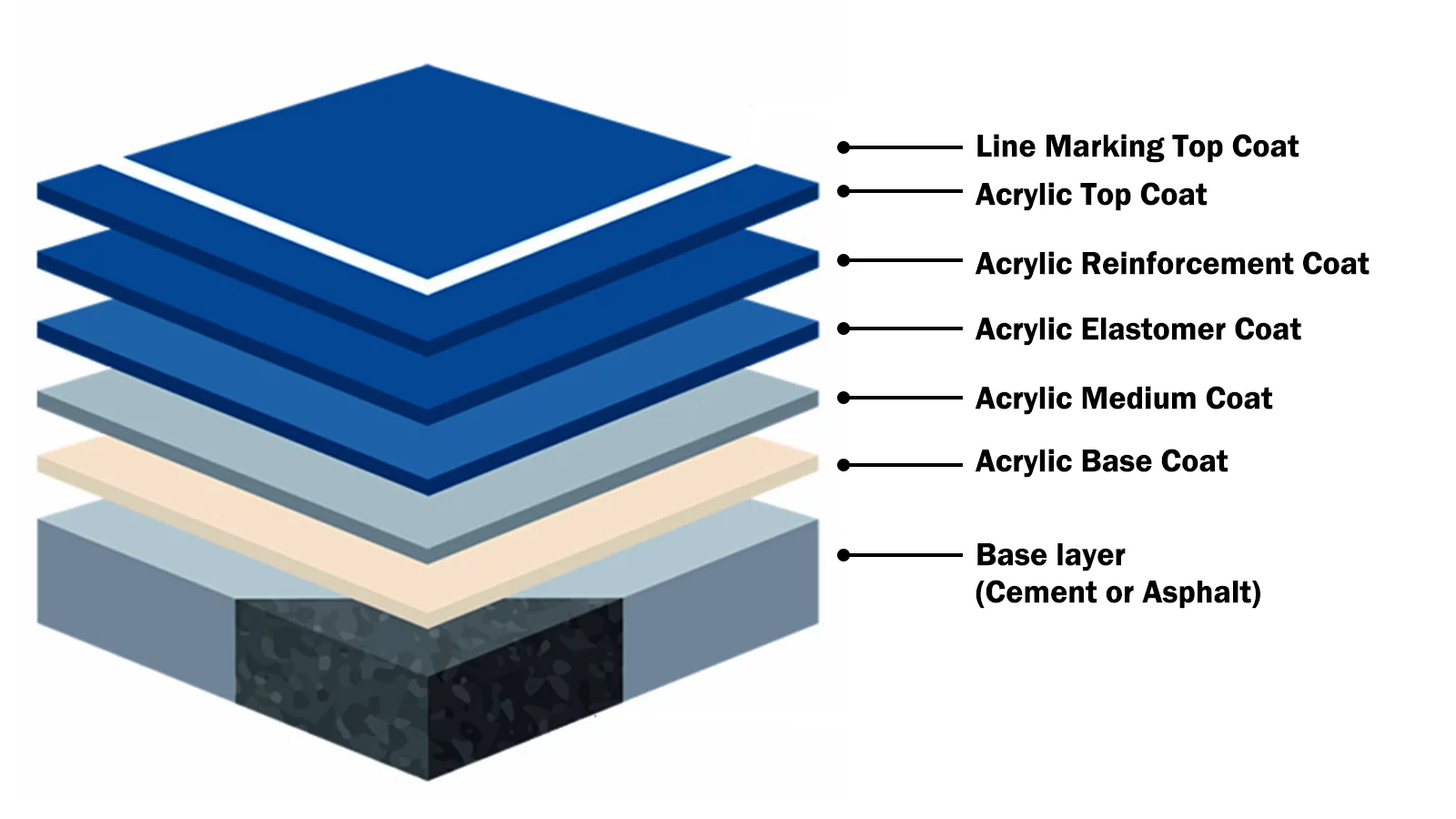

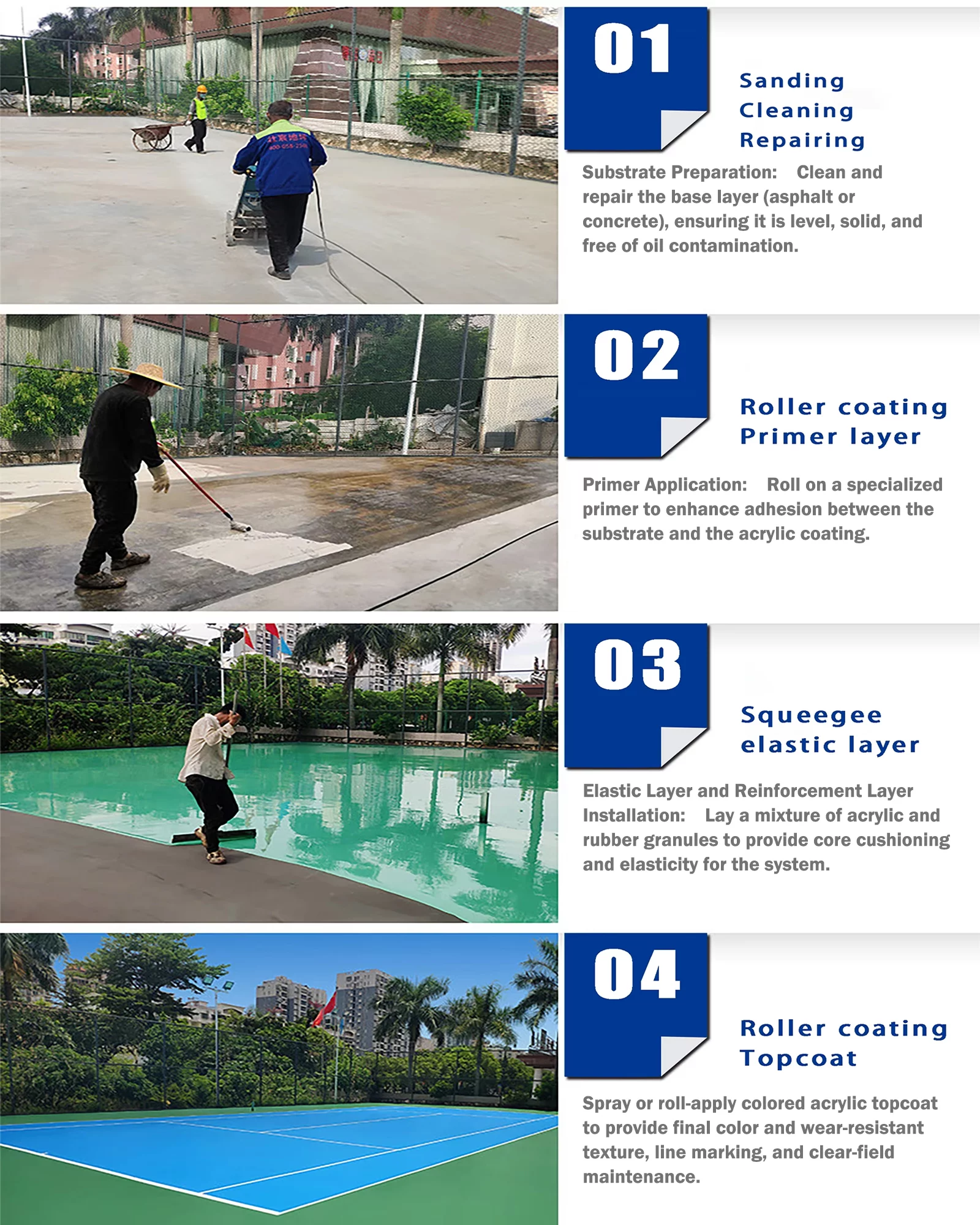

1. Preparación del sustrato: Limpiar y reparar la capa de base (asfalto u hormigón), asegurándose de que esté nivelada, sólida y libre de contaminación por aceite.

2. Aplicación de imprimación: Aplique con rodillo una imprimación especializada para mejorar la adherencia entre el sustrato y el revestimiento acrílico.

3. Instalación de la capa elástica: Coloca una mezcla de gránulos acrílicos y de caucho para proporcionar el núcleo de amortiguación y elasticidad del sistema.

4. Aplicación de la capa de refuerzo: Aplique una capa de árido fino para rellenar los huecos, creando una base lisa y sólida para la capa final.

5. Aplicación de capas de textura: Aplique con pistola o rodillo un acabado acrílico coloreado para dar el color final y una textura resistente al desgaste.

6. Marcado de líneas: Aplique cinta adhesiva a las dimensiones estándar y, a continuación, rocíe o aplique con rodillo pintura especializada para marcar líneas.

7. Desbroce y curado: Despeje la zona, instale barreras y permita el curado natural durante al menos 72 horas antes de su uso.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegrama:+86 1375 1210 938

Telegrama:+86 1375 1210 938 Correo electrónico: ceo@dc-surface.com

Correo electrónico: ceo@dc-surface.com Dirección:No:332 Dalang Town Dongguan City China 523000

Dirección:No:332 Dalang Town Dongguan City China 523000