مخصص حسب حجم الموقع

موك: من 500 متر مربع

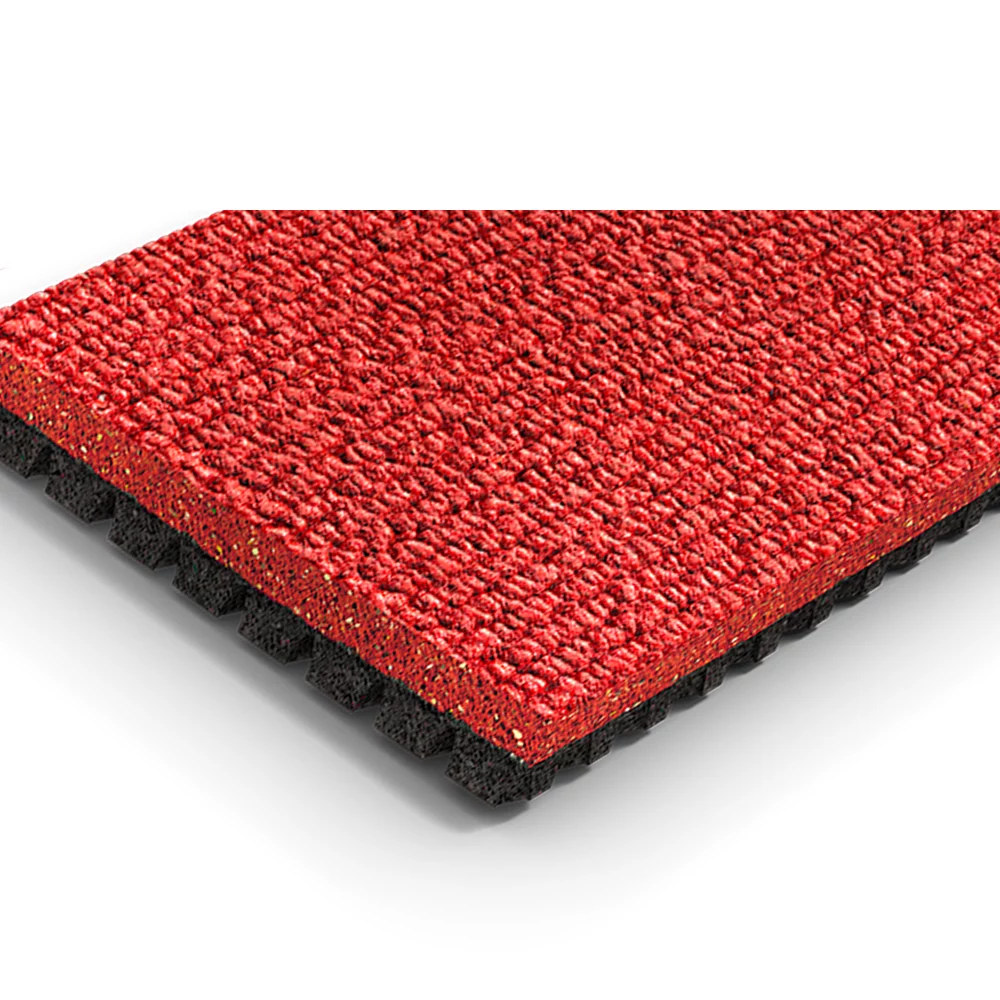

البند: مضمار جري مطاطي مسبق الصنع

المادة: المطاط الطبيعي

السُمك: 13 مم (4 + 9) أو حسب الطلب

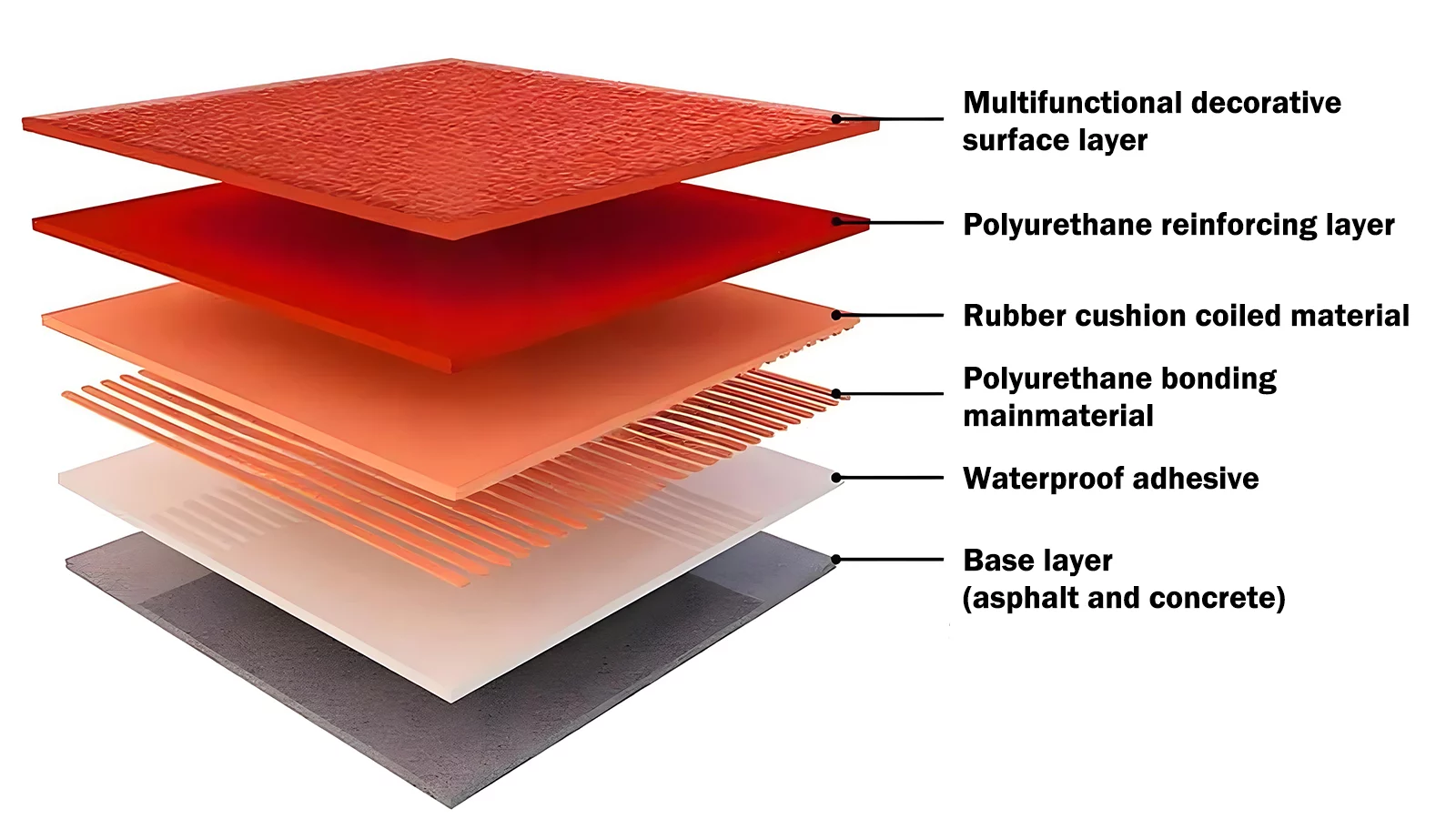

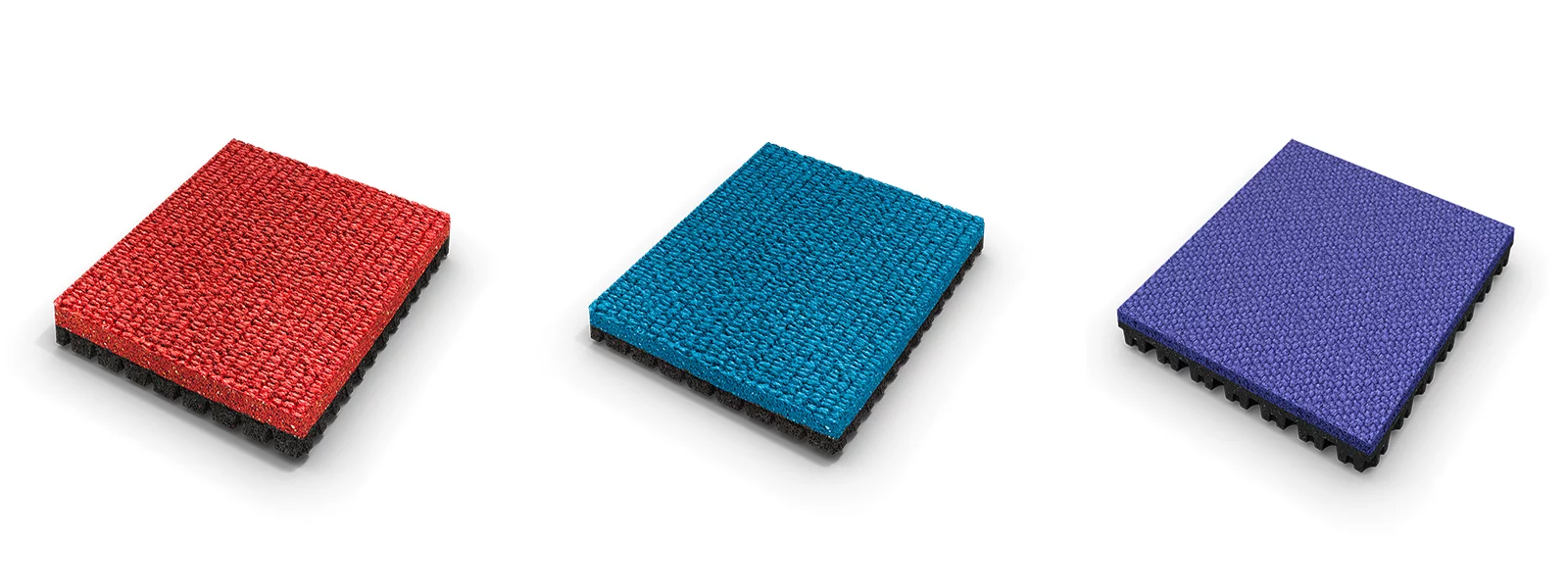

لون السطح: أحمر، أزرق، أخضر، أخضر، بنفسجي، رمادي

اللون السفلي: رمادي، بني، أسود

| اسم المنتج | مضمار تشغيل النظام الجاهز مسبق الصنع | محتوى المنتج من المطاط | علوي/60% (± 1%)، سفلي/55% (± 1 %) |

| الميزة | مسبقة الصنع لسهولة التركيب والأداء الرياضي الرائع والآمن والصديق للبيئة | امتصاص الصدمات (%) | 41% (± 1%) |

| القاعدة | الأسمنت أو الأسفلت | التشوه العمودي (مم) | 1.6 مم (± 1 مم) |

| اللون | الأحمر والأزرق والبنفسجي والأخضر والأزرق والأرجواني والمخصص | قوة الشد (ميجا باسكال) | 1.17 ميجا باسكال(±0.1 ميجا باسكال) |

| السُمك | 9-15.9 ملم (أو حسب الطلب) | استطالة الشد (%) | 235%(±20%) |

| الضمان | 2 سنة | صلابة الشاطئ(°) | 55° |

| الشهادة | الاتحاد الدولي لألعاب القوى | قيمة مضادة للانزلاق | ≥47 BPN20℃ |

| التطبيق | ملعب، وملعب رياضي، ومركز رياضي، ومركز رياضي، ومدارس، وحديقة للركض وما إلى ذلك. | مقاومة الحرائق | 1 درجة |

1. لا توجد جزيئات مطاطية، لا تحلل، مثالية للاستخدام المتكرر

2. امتصاص جيد للصدمات، وأداء ممتاز في الارتداد، والتصاق جيد، ومقاومة قوية للمسامير.

3. أداء مضاد للانزلاق ومقاوم للتآكل، حتى في الأيام الممطرة لا يتأثر الأداء

4. قدرة غير عادية على مقاومة الشيخوخة، ومضادة للأشعة فوق البنفسجية، واللون متين ومستقر غير لامع، ولا يوجد انعكاس للضوء، ولا شعور بالإبهار

5. قولبة مسبقة الصنع، سهلة التركيب

6. الاستخدام في جميع الأحوال الجوية، وعمر الخدمة الطويل، وسهولة الصيانة، وانخفاض تكاليف الصيانة.

7. مثبطات اللهب، والعزل، وأداء عزل الصوت، والوقاية من الحرائق، والأداء العالي للسلامة

8. غير سامة، غير ضارة، تتماشى مع المتطلبات البيئية

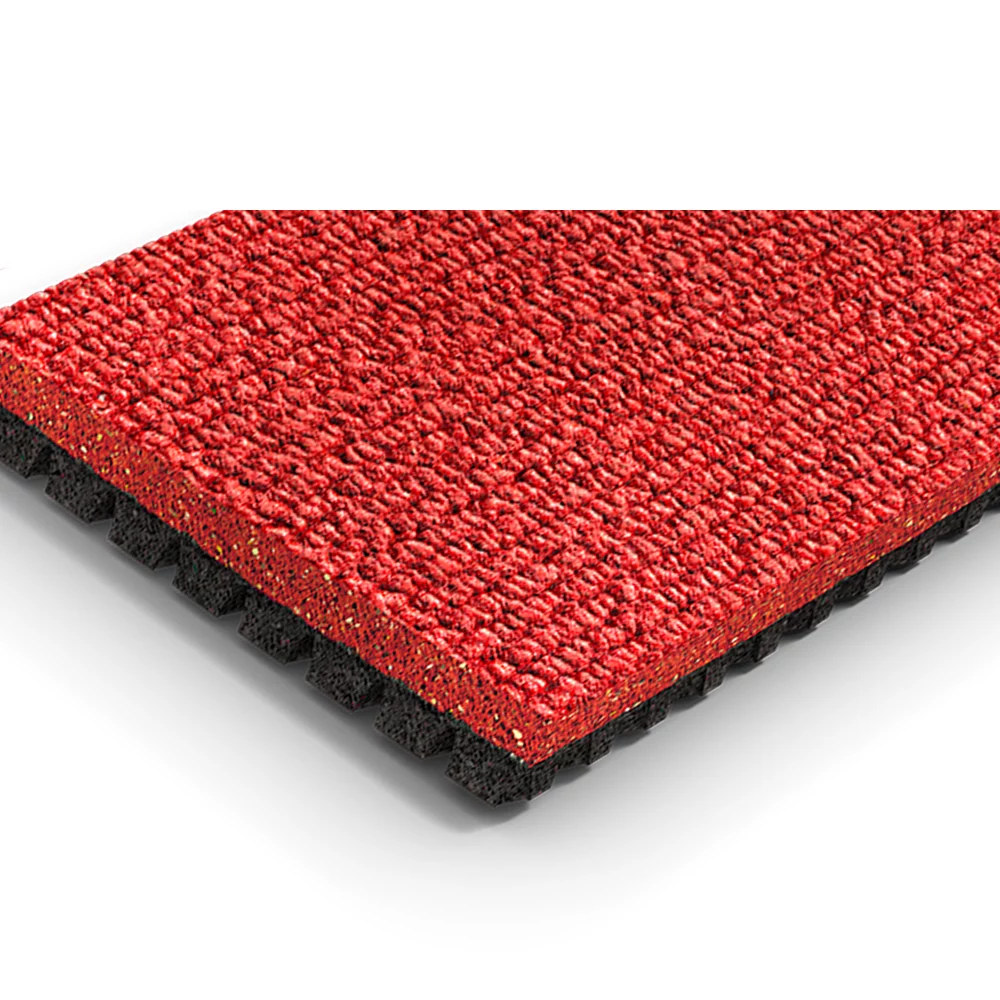

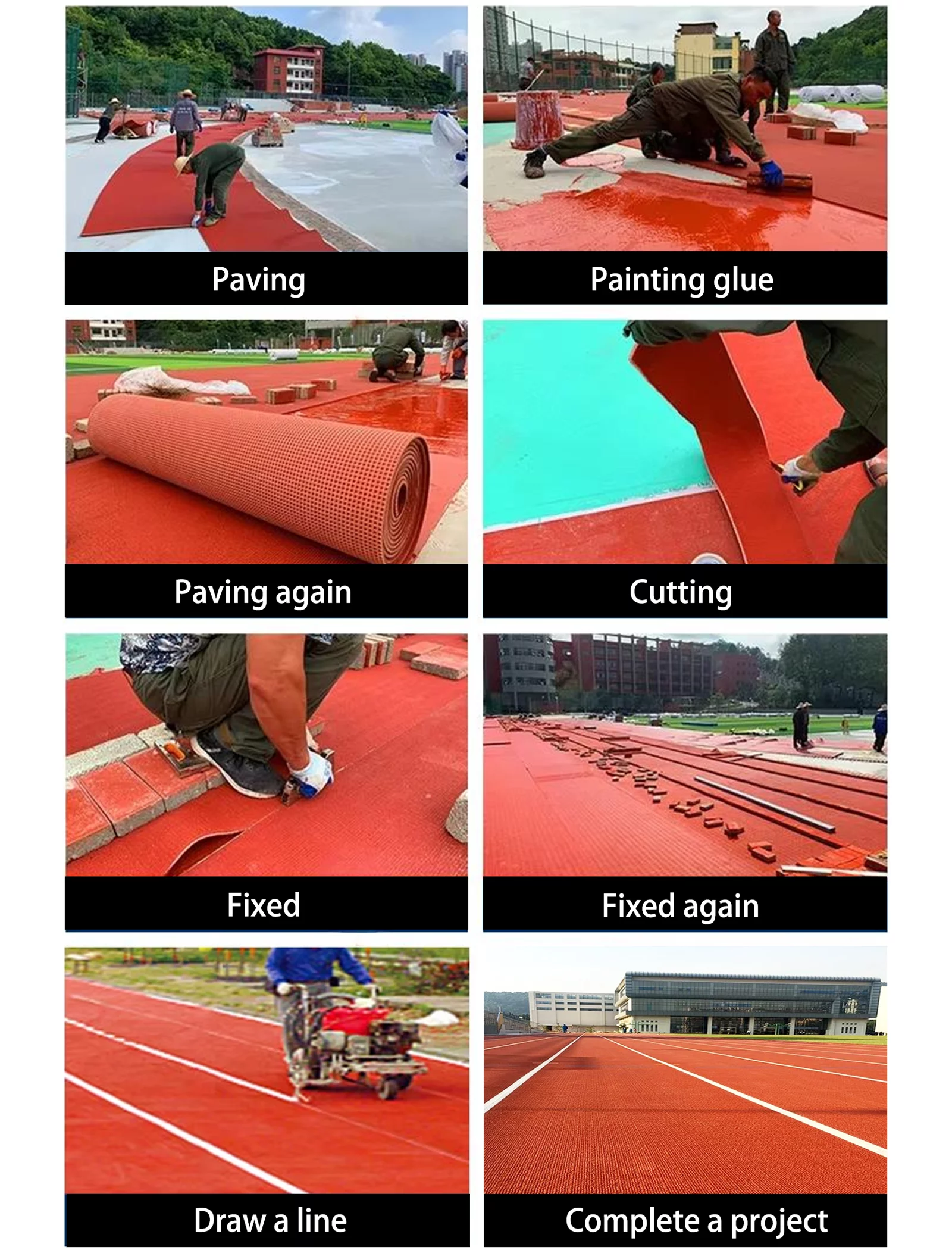

1. نظف الموقع وتأكد من أن القاعدة (خرسانية أو أسفلتية) مستوية وصلبة وخالية من الزيوت والأوساخ.

2. إصلاح الشقوق والحفر وتلميع الأجزاء المرتفعة.

1. تحقق من التسطيح (خطأ 3 أمتار مستقيم ≤ 3 مم)، والانحدار (0.5% ~ 1%)، والقوة (الخرسانة ≥ C25، كثافة الأسفلت).

2. نسبة الرطوبة ≤8% (تحتاج إلى تجفيف).

قم بلفّ مادة البولي يوريثين الخاصة وتطبيقها بشكل موحد على جذور العشب النظيفة (وفقًا لنسبة الشركة المصنعة).

1. قم بمحاذاة الخطوط ووضع الملف من داخل المدرج إلى خارجه.

2. قم بضغط اللفائف أثناء الرصف (استخدم أسطوانة شديدة التحمل للتخلص من الهواء) لضمان عدم وجود فقاعات أو تجاعيد.

3. حجز فواصل التمدد الحراري 1 ~ 3 مم عند ربط مواد اللفائف المتجاورة.

1. استخدم مادة لاصقة من البولي يوريثين المكونة من عنصرين لملء الفجوة وكشطها وإغلاقها.

2. التركيز على ضغط حواف التماس (عملية اللحام الساخن أو عملية الربط على البارد وفقاً لمتطلبات الشركة المصنعة).

1. ضع الخط وفقًا لرسومات التصميم عن طريق لصق الورق المنقوش ورش طلاء رسم الخط من البولي يوريثين الأبيض/الملون.

2. يُزال الورق بعد المعالجة.

قم بإزالة الأنقاض وأغلق الموقع للصيانة لمدة ≥48 ساعة (تجنب الدوس والغطس).

تليفون+86 1375 1210 938

تليفون+86 1375 1210 938 واتساب:+86 1375 1210 938

واتساب:+86 1375 1210 938 برقية+86 1375 1210 938

برقية+86 1375 1210 938 البريد الإلكتروني ceo@dc-surface.com

البريد الإلكتروني ceo@dc-surface.com إضافة:رقم:332 مدينة دالانج بلدة دونجوان مدينة دونجوان الصين 523000

إضافة:رقم:332 مدينة دالانج بلدة دونجوان مدينة دونجوان الصين 523000