مخصص لحجم الموقع

موك: من 500 متر مربع

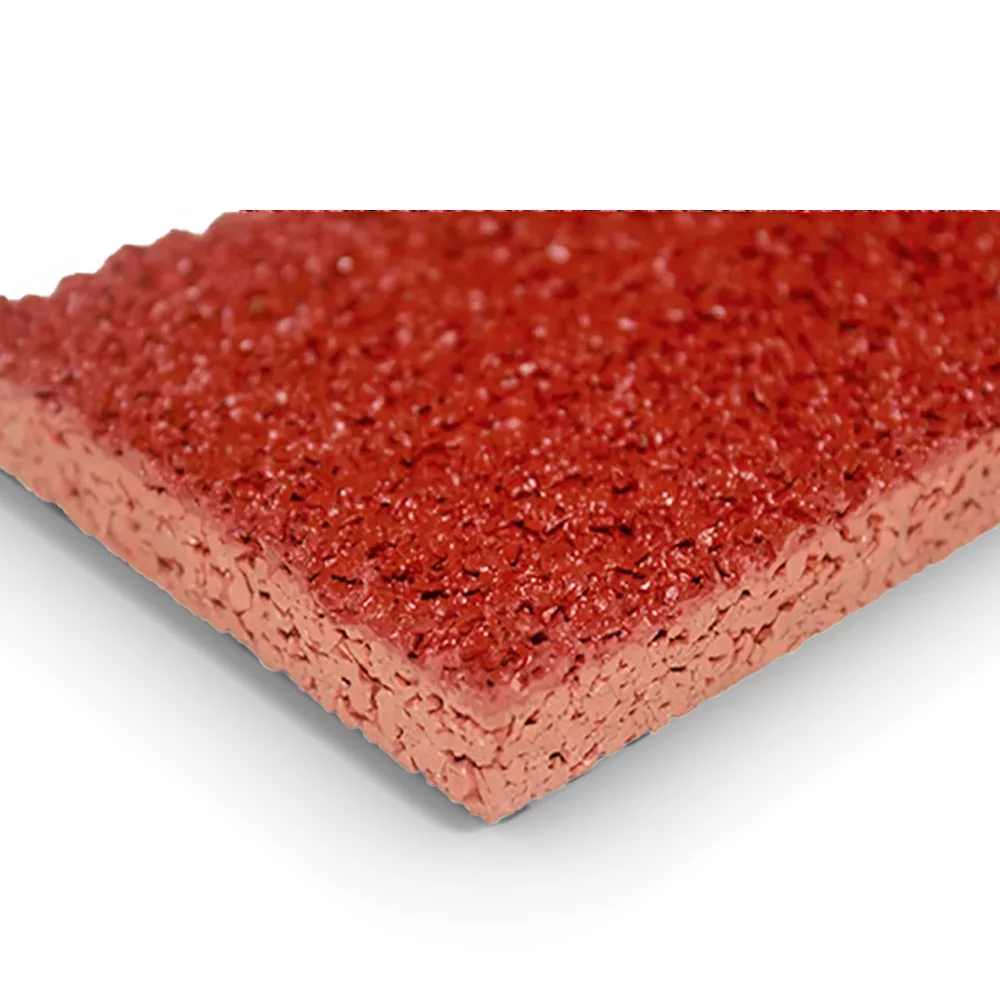

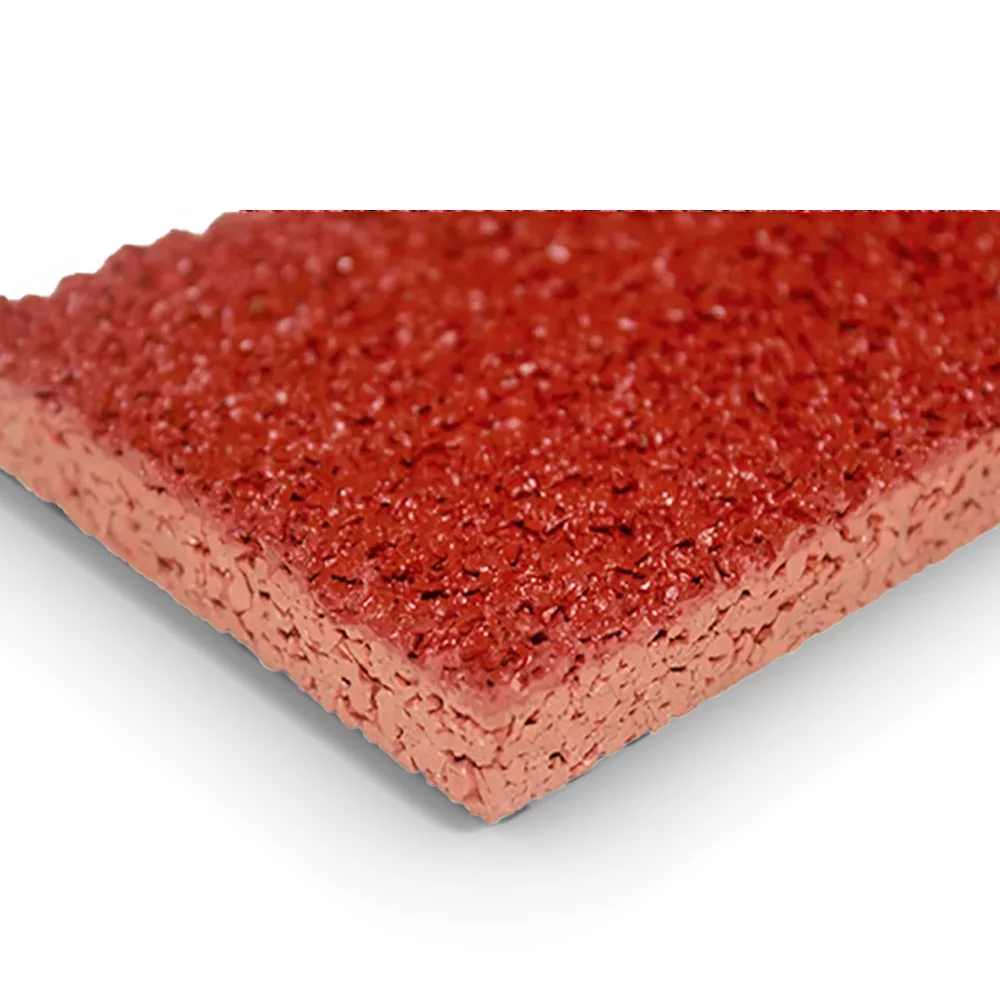

النوع: مضمار جري قابل للتنفس (13-15 مم)

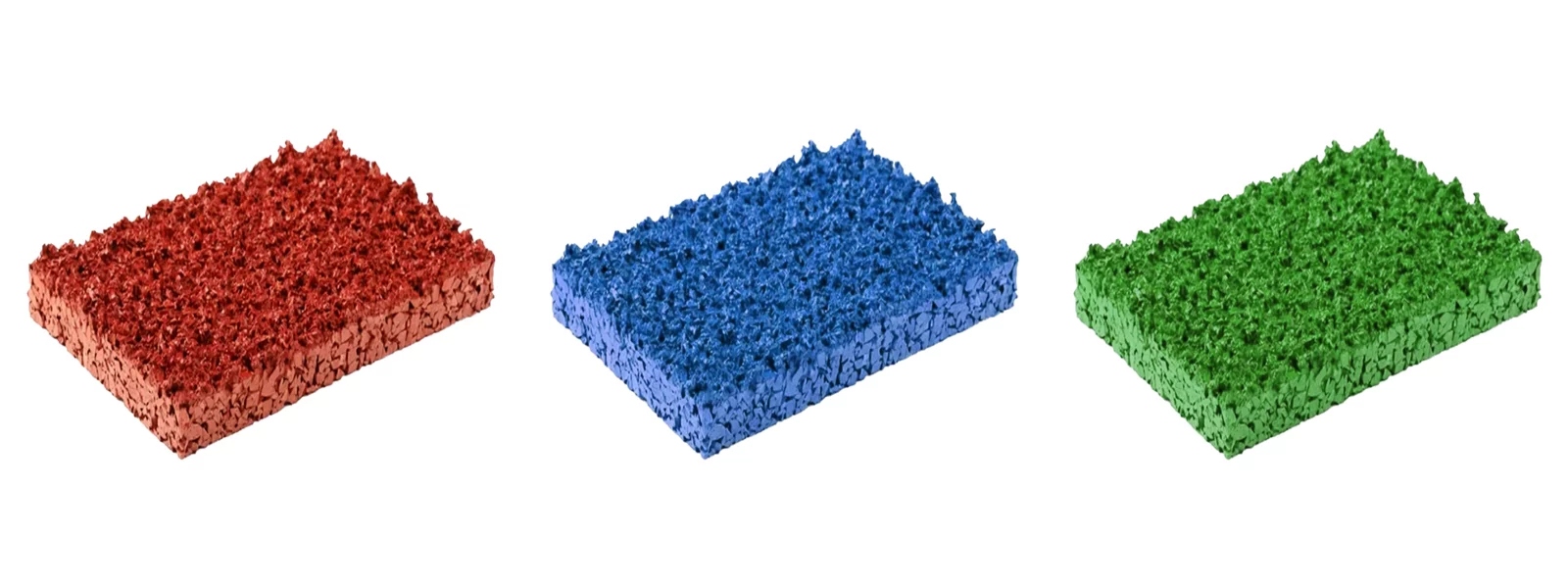

اللون: أحمر، أزرق، أزرق، ألوان أخرى

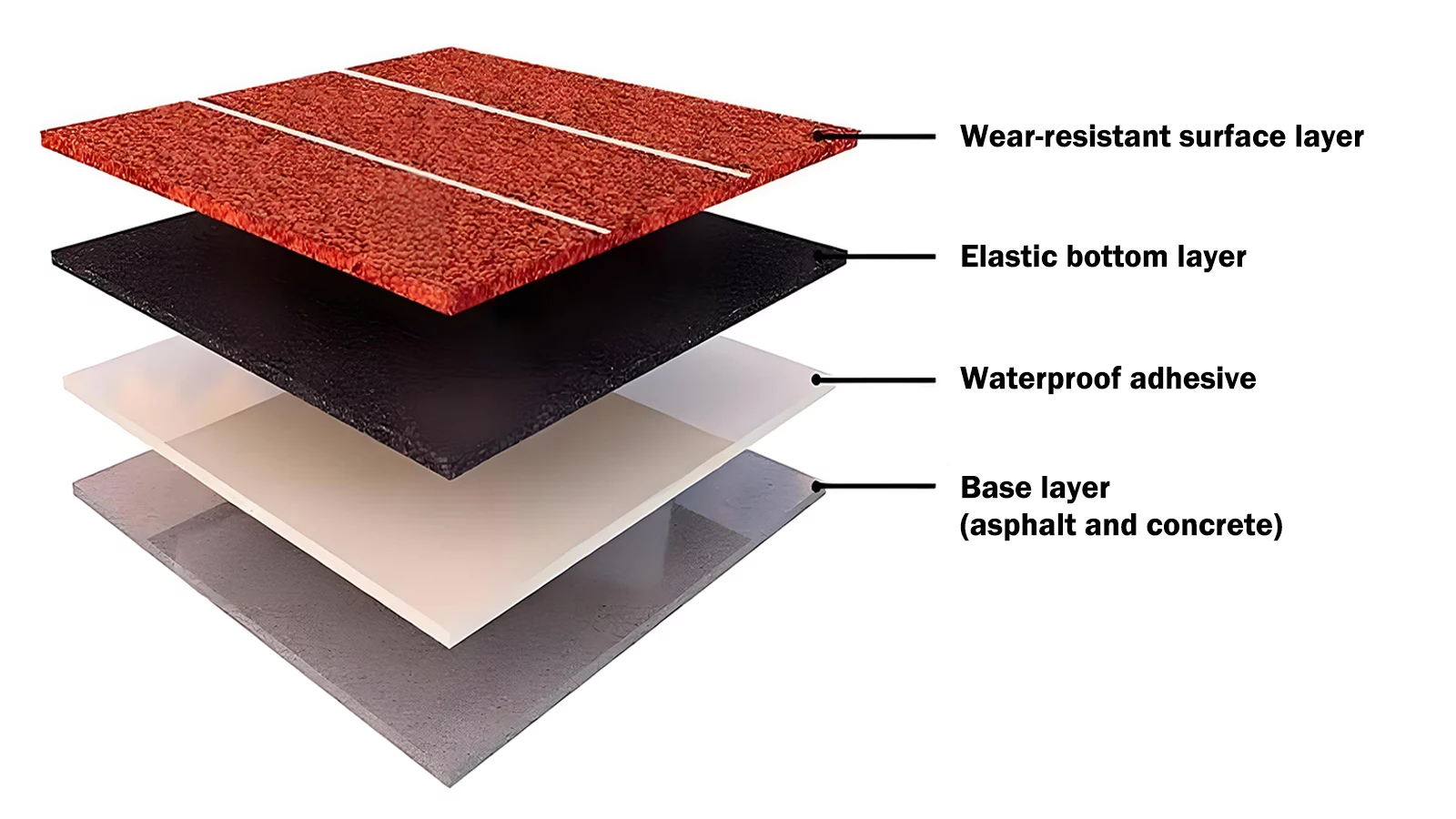

الوصف: 10 مم قاعدة/بطانة SBR سوداء من مادة SBR، وبولي يوريثان 2:1، وسطح مرش بحبيبات EPDM 0.5-1.5

يمكن إضافة طبقة حماية سطحية من البولي يوريثان Si-PU.

| اسم المنتج | مضمار جري بنظام التنفس | محتوى المنتج من المطاط | العلوي/25% (±1%)، السفلي/20% (±1 %) |

| الميزة | الاختيار الأول لجميع المدارس والمناطق الممطرة، بدون فقاعات، اقتصادي | امتصاص الصدمات (%) | 40% (± 1%) |

| القاعدة | الأسمنت أو الأسفلت | التشوه العمودي (مم) | 1.6 مم (± 0.1 مم) |

| اللون | الأحمر والأزرق والبنفسجي والأخضر والأزرق والأرجواني والمخصص | قوة الشد (ميجا باسكال) | 0.7 ميجا باسكال(±0.1 ميجا باسكال) |

| السُمك | 9-15.9 ملم (أو حسب الطلب) | استطالة الشد (%) | 91%(±5%) |

| الضمان | 2 سنة | صلابة الشاطئ(°) | 55° |

| الشهادة | الاتحاد الدولي لألعاب القوى | قيمة مضادة للانزلاق | ≥47 BPN20℃ |

| التطبيق | ملعب، وملعب رياضي، ومركز رياضي، ومركز رياضي، ومدارس، وحديقة للركض وما إلى ذلك. | مقاومة الحرائق | 1 درجة |

مسار الجري القابل للتنفس بواسطة جزيئات حماية البيئة من نفايات المطاط البلاستيكية المستعبدين من البلاستيك لحماية البيئة للطبقة السفلية، والطبقة السطحية مع جزيئات البولي يوريثين ورش مزيج الطين البلاستيكي وتصبح. بالإضافة إلى مزايا الأشكال الأخرى من نفاذية المياه، والنوع القابل للتنفس، ولكن يمكن استخدامه أيضًا في جميع الأحوال الجوية، فهو الأكثر اقتصادية، والأكثر فعالية من حيث التكلفة، ولن تحدث ظاهرة الانتفاخ، ولكنه يقلل أيضًا من استثمار رأس المال الأساسي، وهو مناسب جدًا للاستخدام التدريبي لوضع المجال الرياضي.

1. التجفيف السريع بعد المطر: الهيكل قابل للتنفس ونفاذية المياه، ويمكن لمياه الأمطار أن تتسرب بسرعة إلى الطبقة السفلية وتصرف بعيدًا، ويمكن استخدامها مرة أخرى في وقت قصير بعد المطر.

2. آمن وغير قابل للانزلاق: يوفر نسيج جسيمات السطح احتكاكًا جيدًا وفعالاً مانعًا للانزلاق، مما يقلل من خطر الإصابات الرياضية.

3. صديقة للبيئة وصحية: تفي المادة بمعايير حماية البيئة، ولا تنبعث منها رائحة مزعجة، لحماية صحة المستخدم وصديقة للبيئة.

4. متينة وسهلة الصيانة: هيكل مستقر، ومقاومة قوية للطقس (الشمس والصقيع)، وصيانة روتينية بسيطة (سهلة التنظيف والإصلاح).

5. اقتصادية وعملية: بالمقارنة مع المدرج البلاستيكي الكامل، فإن كمية المواد أقل، وتكلفة البناء منخفضة نسبيًا، وأداء التكلفة أعلى.

6. البناء السريع: باعتماد عملية الرصف، تكون دورة البناء قصيرة نسبياً، ويمكن استخدامها بسرعة.

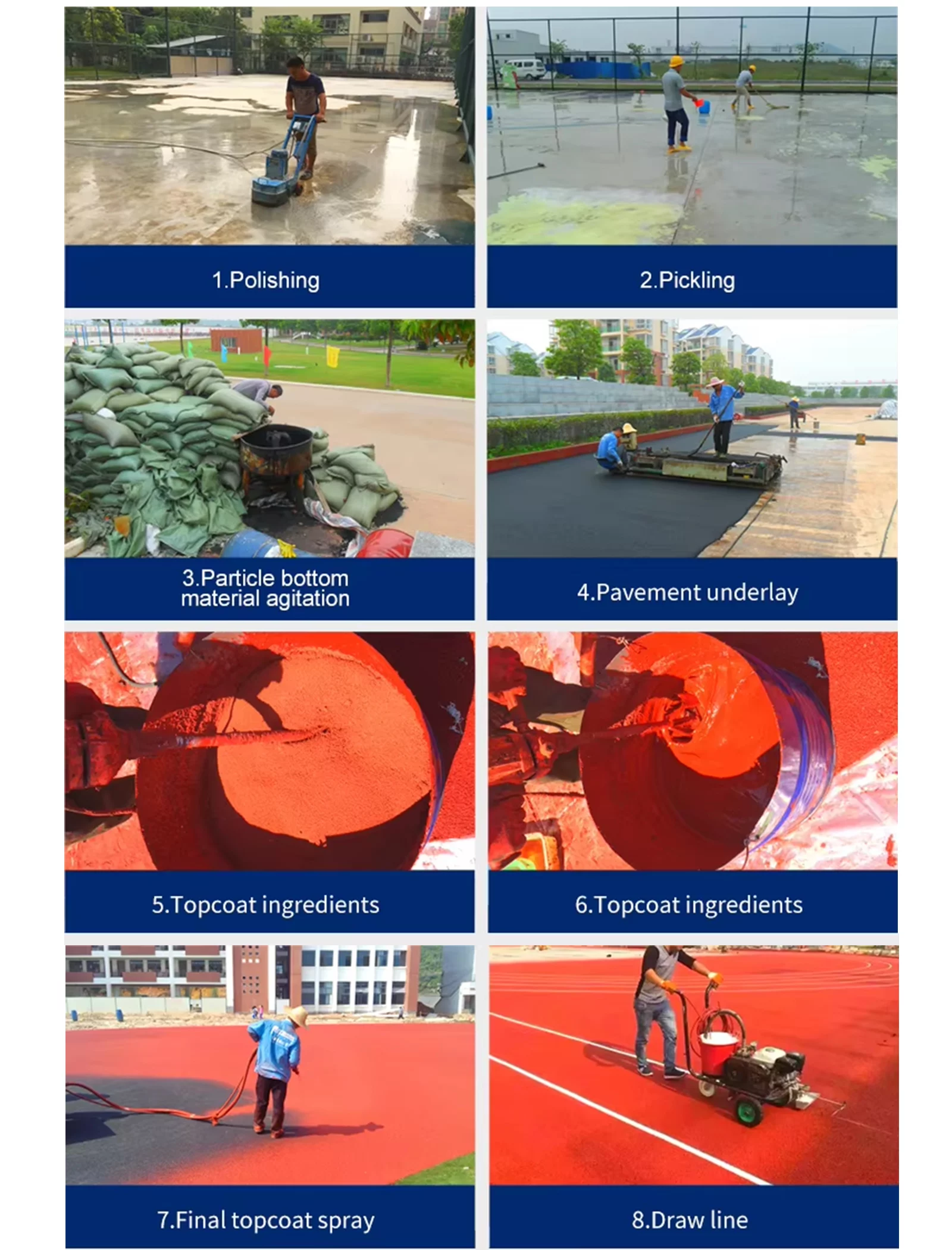

1. نظف الأساس (الخرسانة أو الأسفلت) للتأكد من أنه نظيف وجاف وخالٍ من الشحوم ومفكك.

2. تحقق من أن استواء الأساس وانحداره وقوته تفي بالمتطلبات (عدم وجود ماء، عدم وجود تشققات، عدم وجود رمل).

3. إصلاح العيوب (إن وجدت).

1. ضع غراء خاص مكون من مكون واحد (برايمر) لتعزيز الالتصاق بين الطبقة السطحية وطبقة الأساس.

1. تُخلط حبيبات EPDM + غراء أحادي المكون بنسبة محددة (على سبيل المثال 6:1 أو 7:1) في خلاط جيد.

2. نقل الخليط إلى الموقع ونشره بالتساوي (يدوياً أو ميكانيكياً).

3. استخدم رصفاً خاصاً أو مكشطة خاصة لتسوية والتحكم في السماكة (عادةً 10-13 مم).

1. امزج حبيبات EPDM + غراء مكون واحد + معجون ملون بالتساوي وفقًا للنسبة (عادةً ما تكون نسبة الحبيبات أعلى).

2. استخدم بخاخًا احترافيًا لرش 2-3 مرات بالتساوي وبالعرض.

1. بعد الرش، المعالجة بالحفظ الطبيعي لمدة 24-48 ساعة على الأقل (حسب الطقس ومتطلبات الغراء).

2. وخلال هذه الفترة، يُمنع منعاً باتاً الوطء عليه وصب الماء عليه وتلويثه.

1. قم بقياس الخط ووضعه بدقة وفقًا لرسومات التصميم.

2. استخدم طلاء تعليم خاص لرش أو طلاء خطوط تعليم باللون الأبيض/ألوان أخرى.

1. نظف الموقع تمامًا من الحطام.

تليفون+86 1375 1210 938

تليفون+86 1375 1210 938 واتساب:+86 1375 1210 938

واتساب:+86 1375 1210 938 برقية+86 1375 1210 938

برقية+86 1375 1210 938 البريد الإلكتروني ceo@dc-surface.com

البريد الإلكتروني ceo@dc-surface.com إضافة:رقم:332 مدينة دالانج بلدة دونجوان مدينة دونجوان الصين 523000

إضافة:رقم:332 مدينة دالانج بلدة دونجوان مدينة دونجوان الصين 523000