Customised according to site area

Minimum order quantity: 500 square metres

Application scenarios:Suitable for flooring applications in large shopping malls, mid-to-high-end commercial buildings, luxury clubs, exhibition halls, hotel lobbies, residences, and villas.

Description:Possesses all the outstanding properties of epoxy resin flooring; can be designed into various patterns, offering design flexibility.

Epoxy terrazzo flooring is a premium seamless artistic flooring system. It is created by mixing colored epoxy resin with selected aggregates (such as glass, quartz, shells, etc.), followed by on-site application, curing, and multiple rounds of precision grinding and polishing. Its surface achieves ultimate flatness and mirror-like gloss, with unlimited customization options for patterns and colors, delivering stunning visual cohesion and artistic decorative effects. Simultaneously, it inherits the superior properties of epoxy materials: exceptional wear resistance, high compressive strength, seamless dustproofing, and easy maintenance. As the premier choice for those seeking both aesthetics and functionality, it is widely used in high-end commercial spaces, airports, hotels, exhibition halls, medical facilities, and similar venues.

| Project | Component A | Component B | ||

| Color | Customisable | Pale yellow or transparent | ||

| Proportion | 1.55±0.05 | 0.95±0.02 | ||

| Ratio | Component A/Component A=3:1 | |||

| Curing time | Surface-Dry | 12H (10℃) | 10H(25℃) | 5H (30℃) |

| Pedestrian | 48H (10℃) | 36H(25℃) | 24H(30℃) | |

| Heavy Load | 7 Days(10℃) | 4 Days(25℃) | 2 Days(30℃) | |

| Available Time | 0.5H (10℃) | 0.4H(25℃) | 0.25H(30℃) | |

| VOC | ≤2%(After mixing) | |||

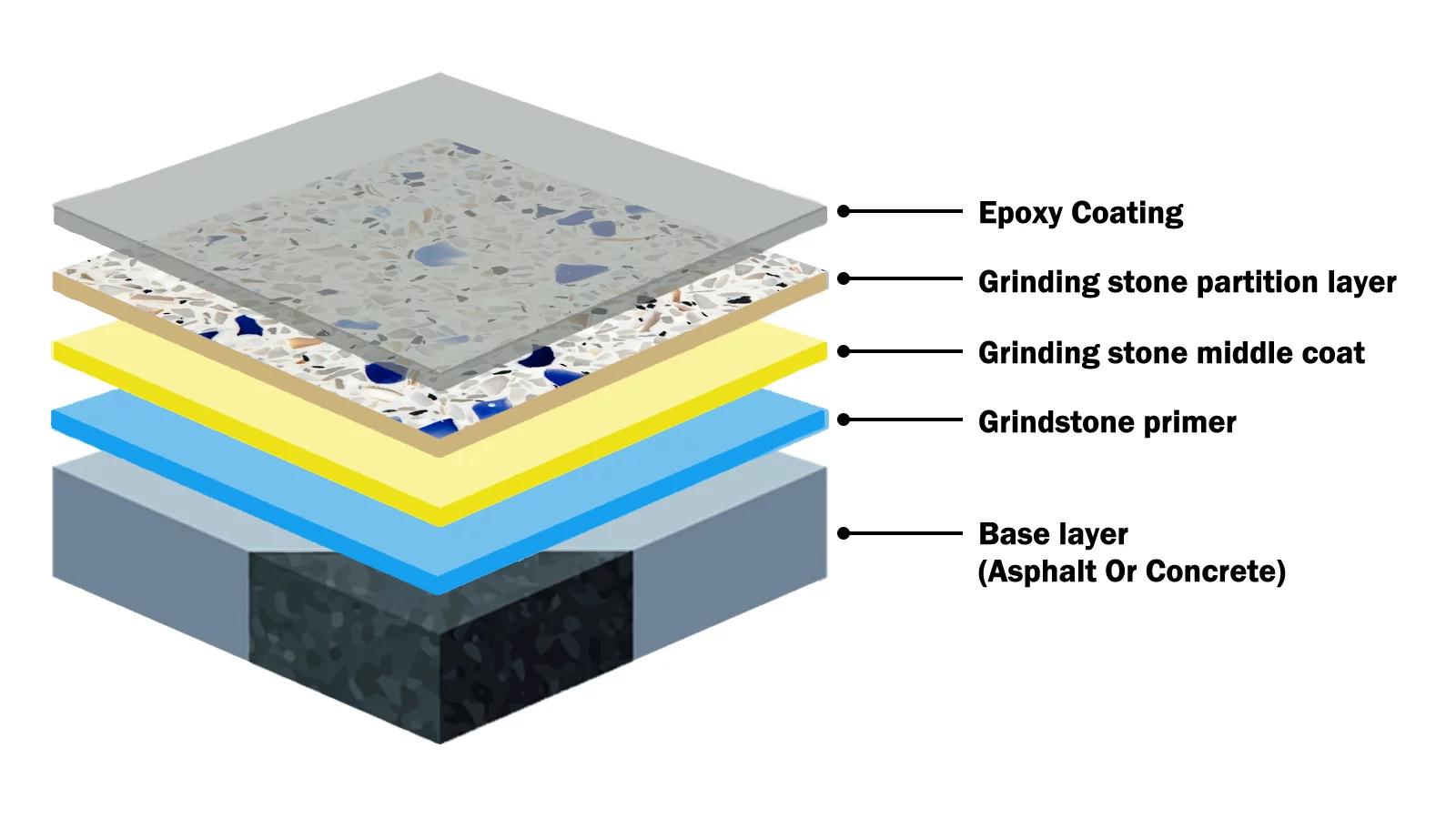

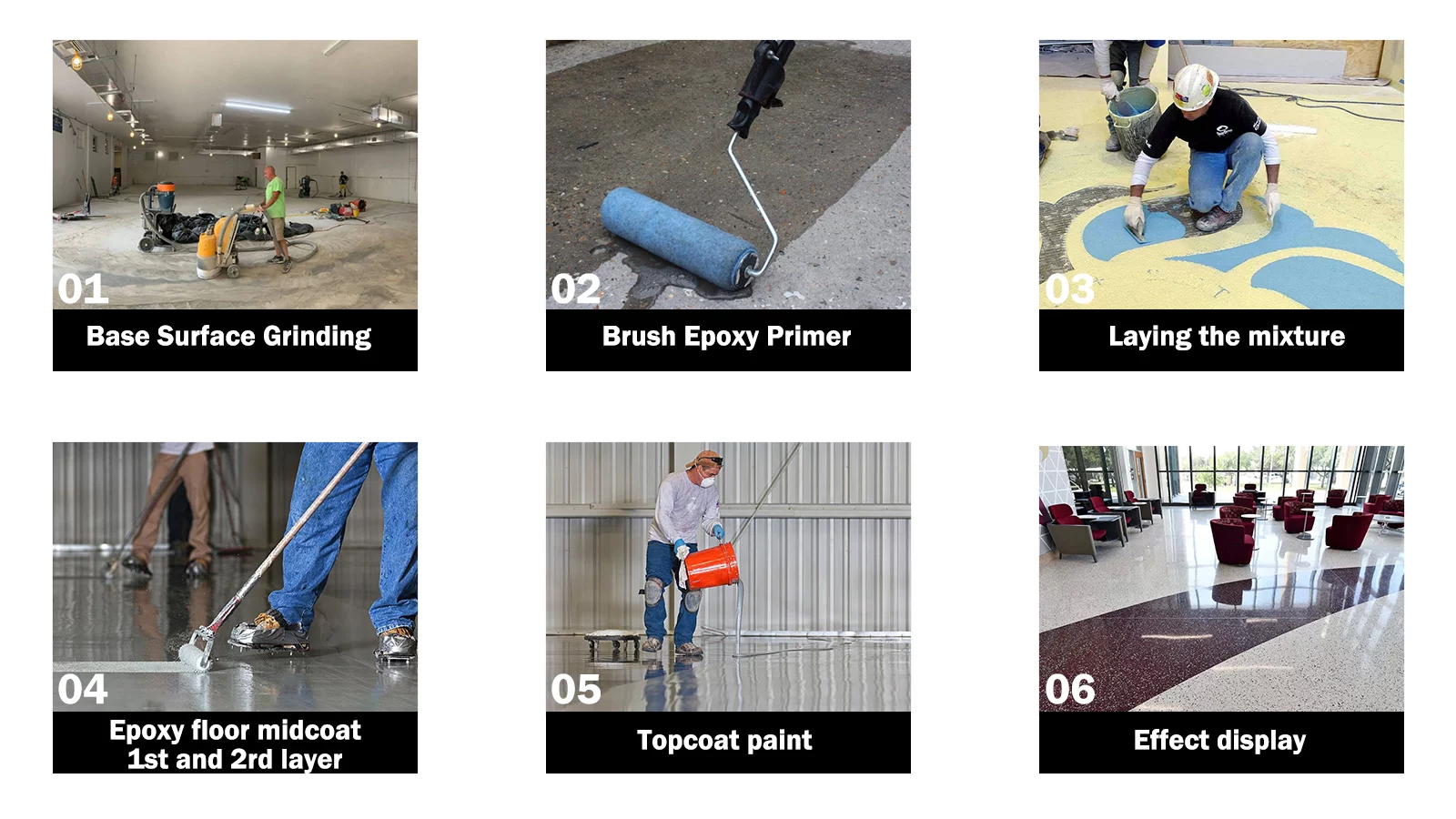

1. Substrate Preparation and Grinding: Perform high-precision milling or grinding on concrete substrates to achieve exceptional flatness and a solid surface. Thoroughly remove all contaminants to establish a flawless foundation for subsequent processes.

2. Epoxy Primer Application: Roll-apply high-performance epoxy primer to fully penetrate and seal the substrate. This step reinforces the base layer, prevents blistering, and ensures robust adhesion to the intermediate layer.

3. Epoxy Terrazzo Mix Installation: On-site blending of custom-formulated colored epoxy resin with selected aggregates (e.g., glass flakes, quartz particles, shells) is thoroughly mixed. The mixture is then spread, compacted, and leveled according to the design pattern.

4. Fine Grinding and Polishing: After complete curing, use large grinding machines with progressively finer grit discs for multi-stage cross-grinding (coarse, medium, fine) until uniform aggregate layers are exposed, achieving optimal flatness and smoothness.

5. Sealing Protective Layer Application: Apply a transparent epoxy or polyurethane topcoat to the ground and cleaned surface. This seals surface micro-pores, enhances the floor’s abrasion resistance and stain resistance, and highlights the aggregate’s crystalline clarity and mirror-like gloss.

6. Final Curing and Finished Product Protection: Allow sufficient time for thorough curing after completion. Strictly seal off the site during this period to prevent scratches or contamination. The floor may only be put into use once it has achieved its final strength.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000