Customized by Site Size

MOQ:From 500 square metres

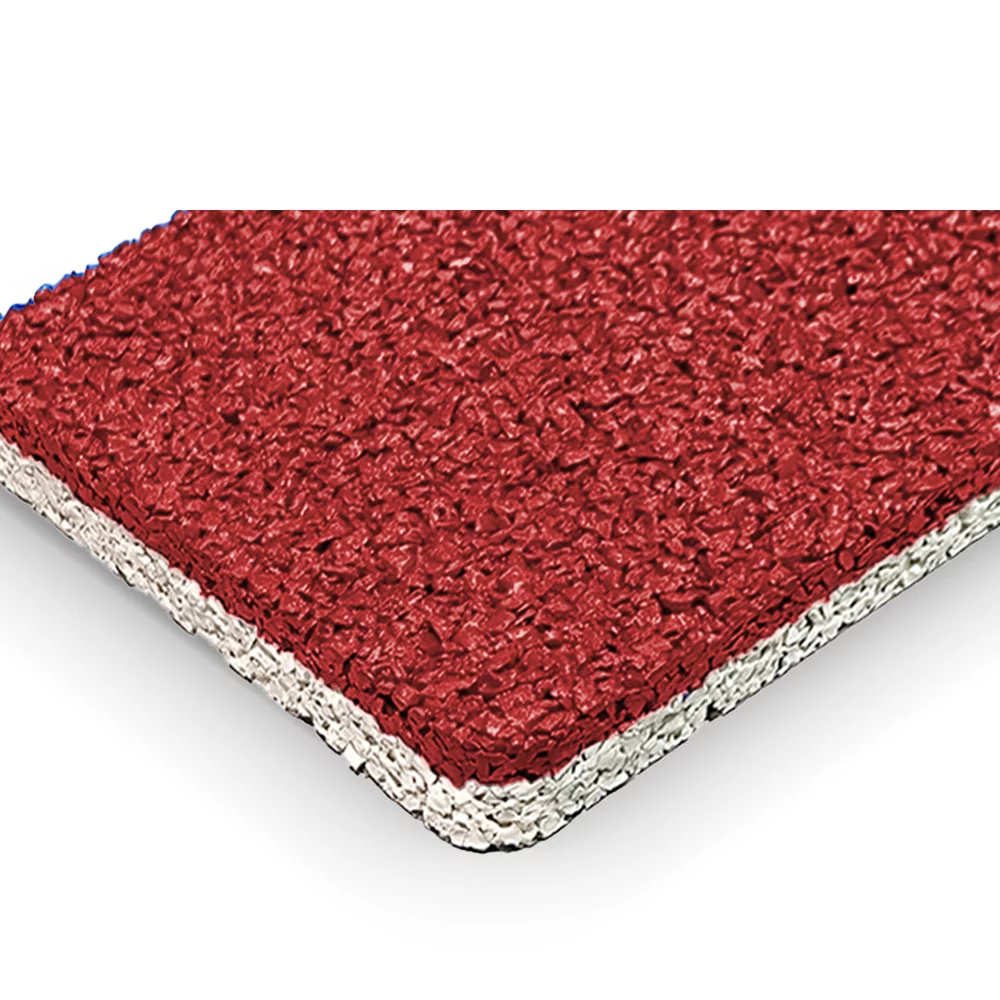

Type: EPDM rubber track

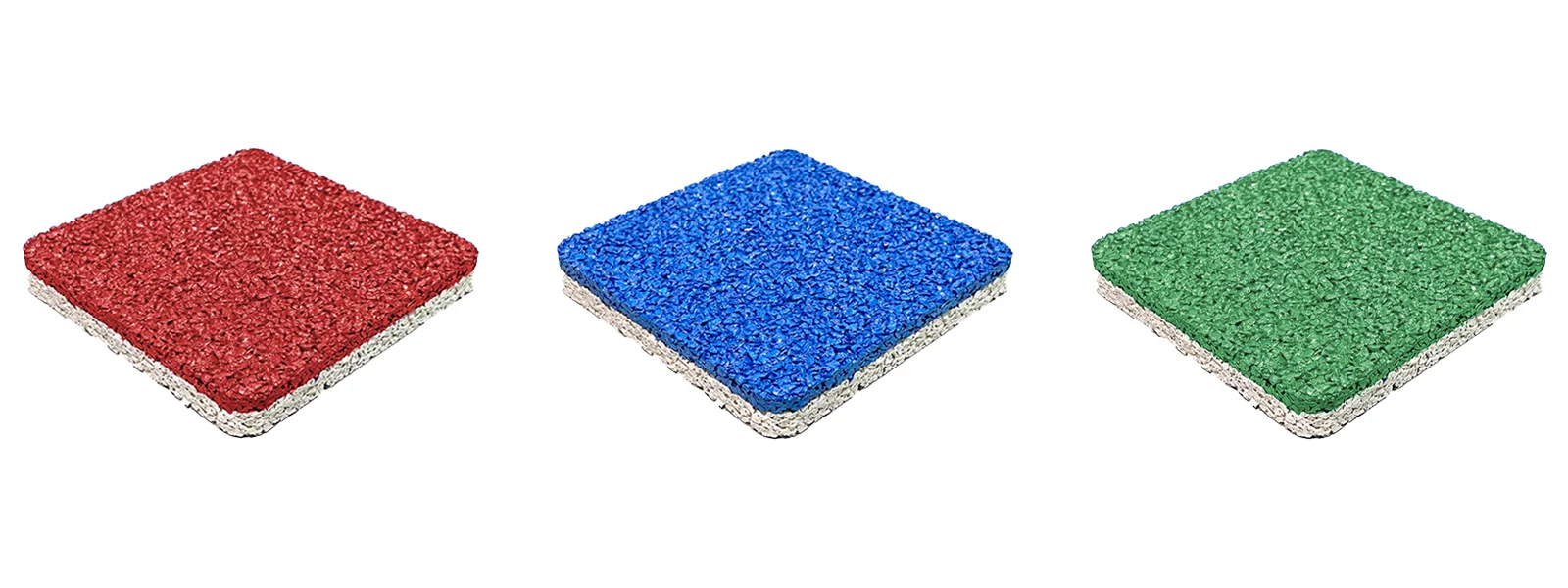

Color: Colorful

Description: puncture-resistant, water-permeable, durable

For institutional and recreational facilities

| Product Name | EPDM Rubber Running Track | Product rubber content | 20%(±1 %) |

| Feature | High elasticity, good weather resistance, rich colors, high safety, and easy maintenance. | Impact absorption(%) | 60%(±1%) |

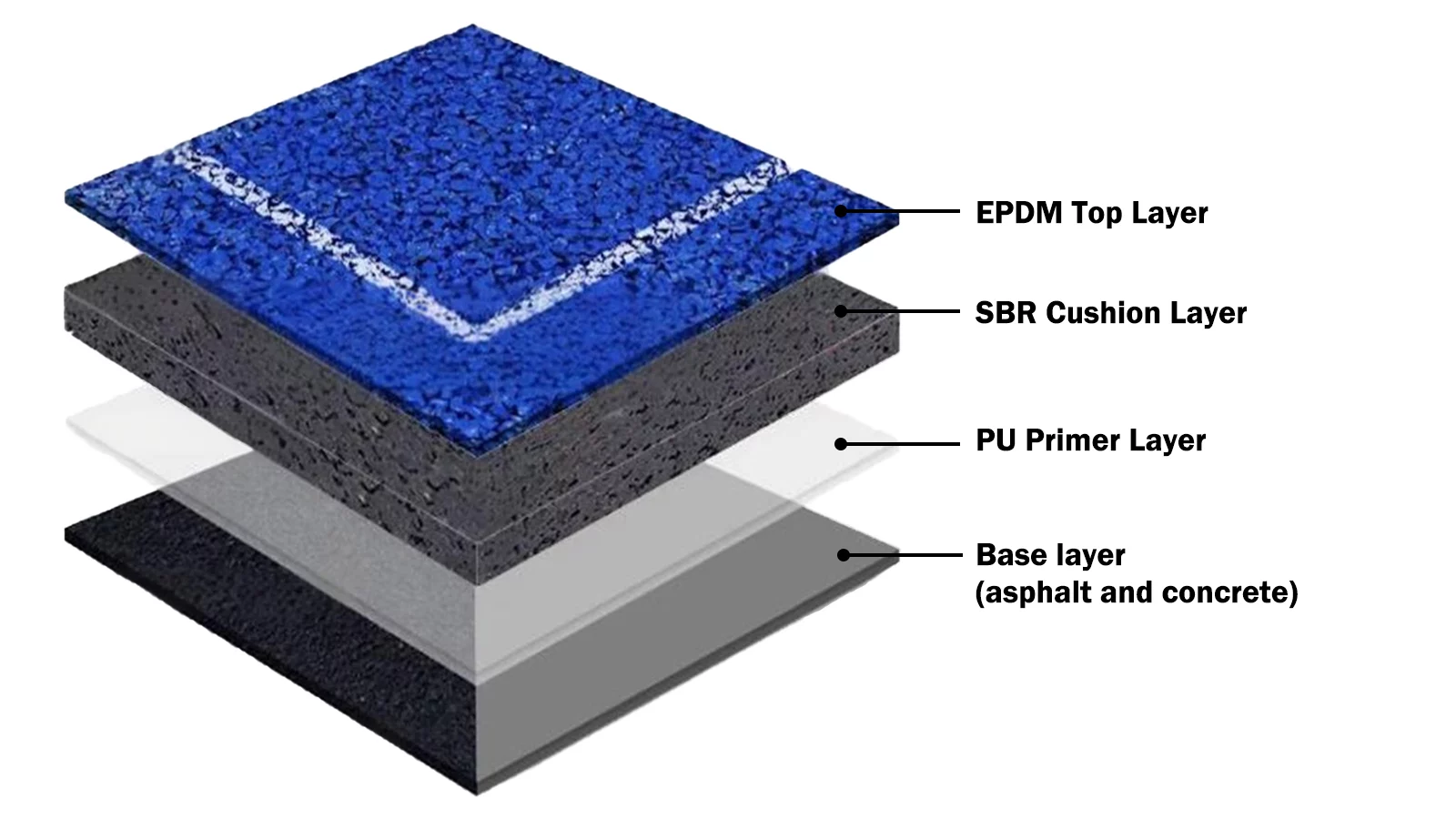

| Base | Cement or asphalt | Vertical deformation(mm) | 1.6mm(±0.1mm) |

| Color | Red, Blue, Purple, Green and customized | Tensile strength(Mpa) | 1.1Mpa(±0.1Mpa) |

| Thickness | 9-13MM(or customized) | Tensile elongation(%) | 90%(±5%) |

| Warranty | 2 Years | Shore hardness(°) | 57° |

| Certificate | ISO,CE,ROHS | Anti-slip value | ≥70 BPN20℃ |

| Application | Children’s playgrounds, jogging parks, leisure parks, etc. | Fire resistance | 1 Grade |

EPDM tracks are a type of high-performance synthetic track widely used in kindergartens, recreational parks, children’s playgrounds, and other similar venues. The core material of these tracks is EPDM (ethylene propylene diene monomer) rubber particles, which are renowned for their exceptional weather resistance, abrasion resistance, and color stability.

This track is typically constructed by mixing high-strength, high-elasticity EPDM particles with polyurethane adhesive, followed by professional installation. Its surface can be designed with anti-slip granular texture, providing excellent shock absorption and energy return functionality. This effectively reduces the risk of sports injuries while enhancing athletic performance and comfort.

1. Excellent weather resistance: UV and ozone resistant, highly resistant to high and low temperatures, does not fade or age.

2. Excellent safety protection: Good elasticity, absorbs impact force, effectively reduces sports injuries.

3. Aesthetic appeal: Rich and durable colours, aesthetically pleasing and conducive to area division.

4. Durable and wear-resistant: Stable physical properties, resistant to compression and wear, with a long service life.

5. Environmentally friendly and non-toxic: Made from non-toxic, odourless materials, recyclable, and compliant with environmental standards.

6. Easy maintenance: Excellent drainage, easy to clean, and low maintenance costs.

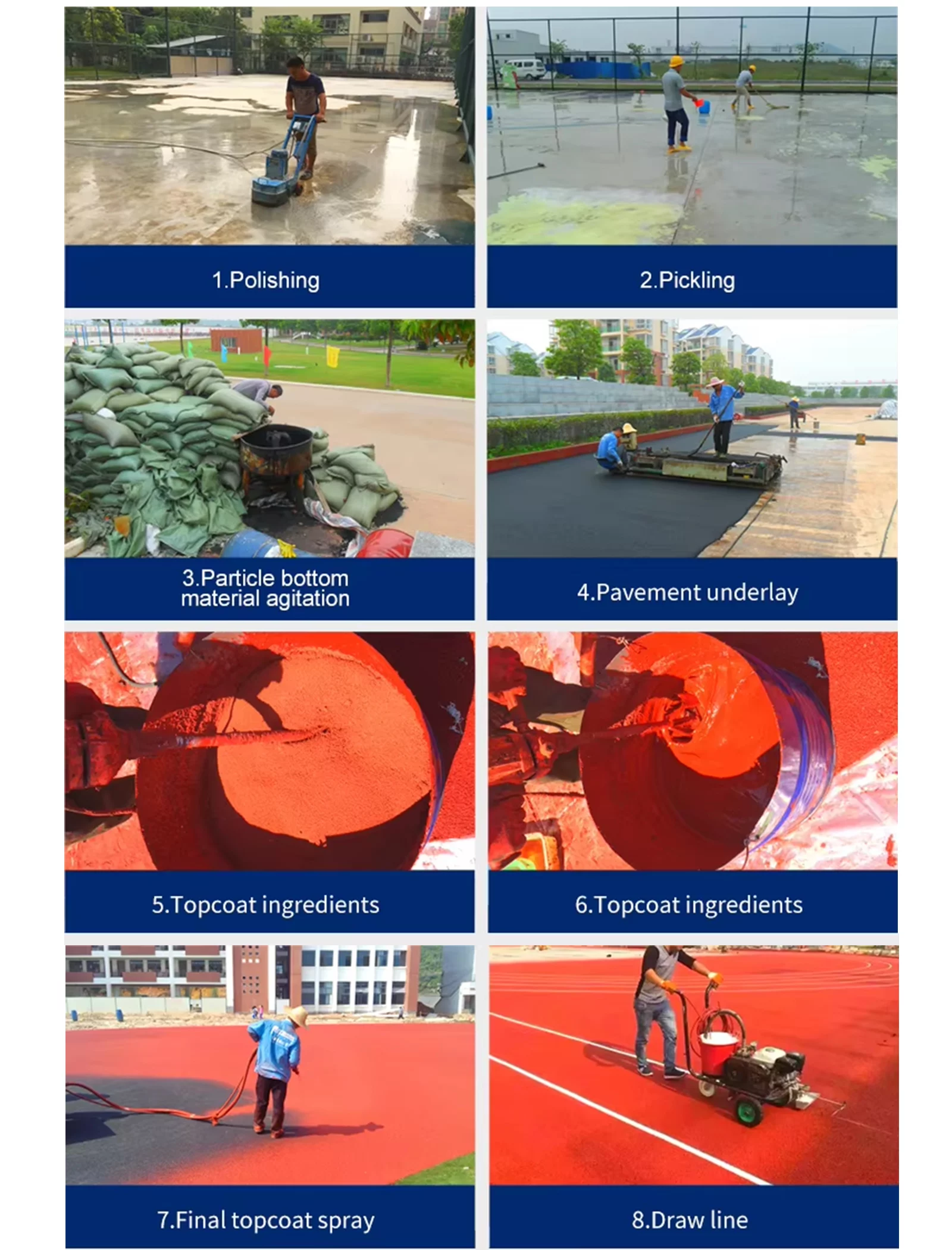

Clean the cement or asphalt base surface, ensuring it is sturdy, level, and free of oil stains, and perform necessary waterproofing or repair treatments.

Apply a specialized adhesive (primer) to the prepared base using a roller to enhance adhesion between the base and the elastic layer.

Mix EPDM granules with specialized polyurethane adhesive in precise proportions using a dedicated mixer, ensuring thorough blending.

Transport the mixed material to the site, spread it out, and use a professional scraper tool to level it, strictly controlling the paving thickness and slope.

Use a specialized compactor to roll the paved elastic layer, ensuring the material is dense, flat, and free of loose particles.

If a more uniform and aesthetically pleasing color is desired, mix EPDM particles with adhesive and apply using a specialized spray machine.

After the elastic layer has fully cured (approximately 24–48 hours), measure and mark the positions according to the design drawings, apply specialized track marking paint, and allow the surface to cure for 5–7 days before use.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000