Customised to site size

MOQ: From 500 square metres

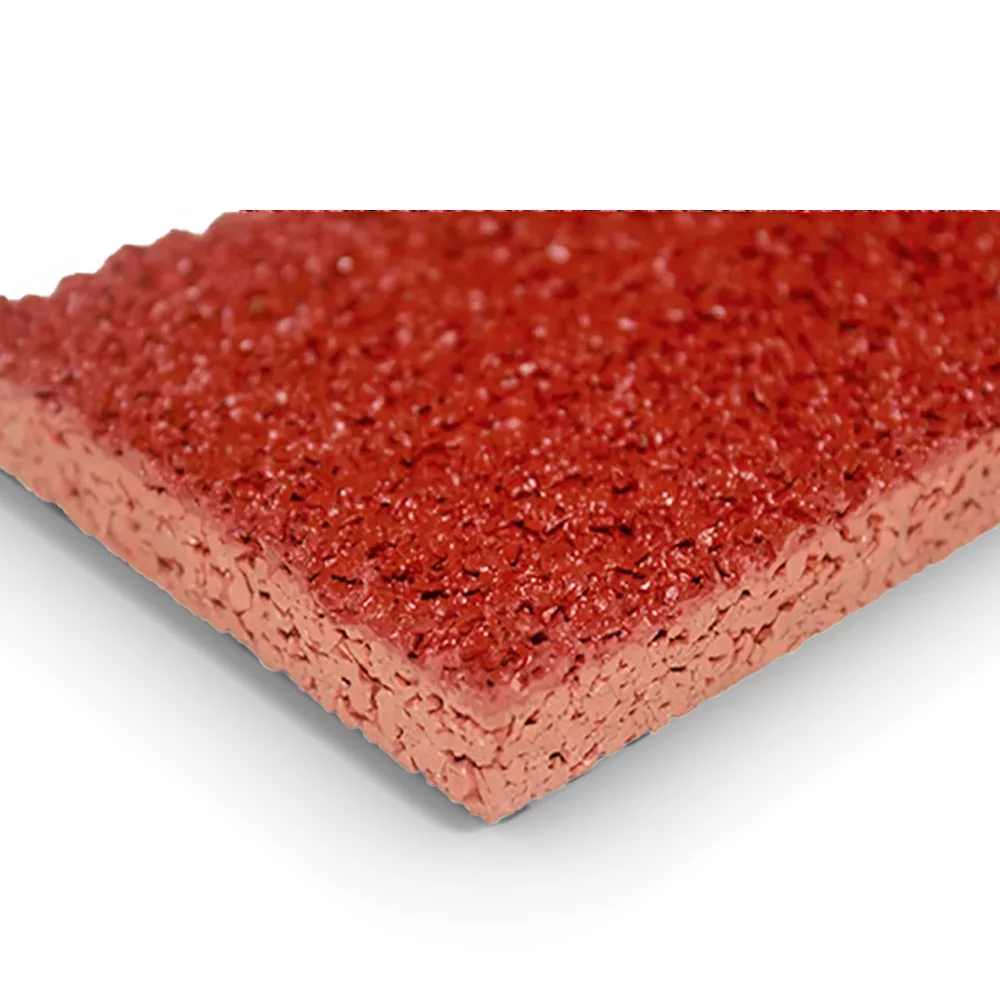

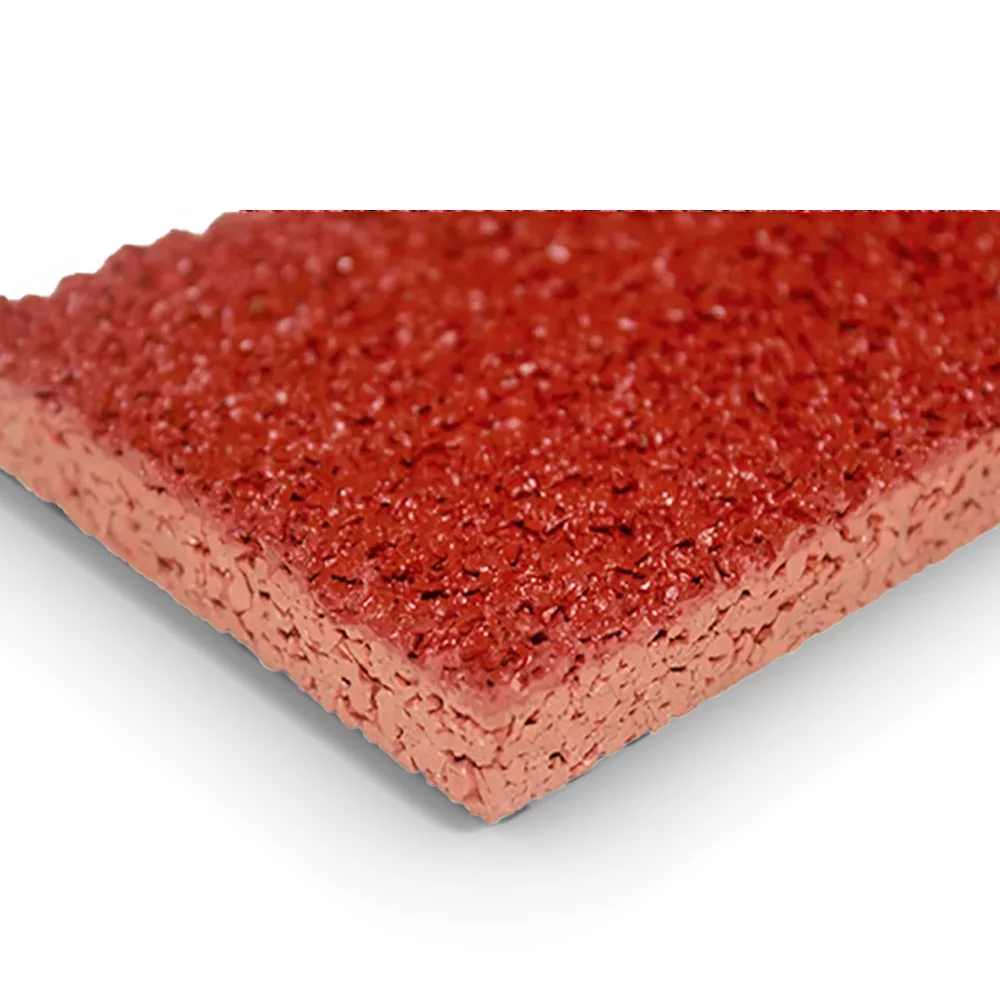

Type: Breathable running track (13-15 mm)

Color: Red, Blue, Other colors

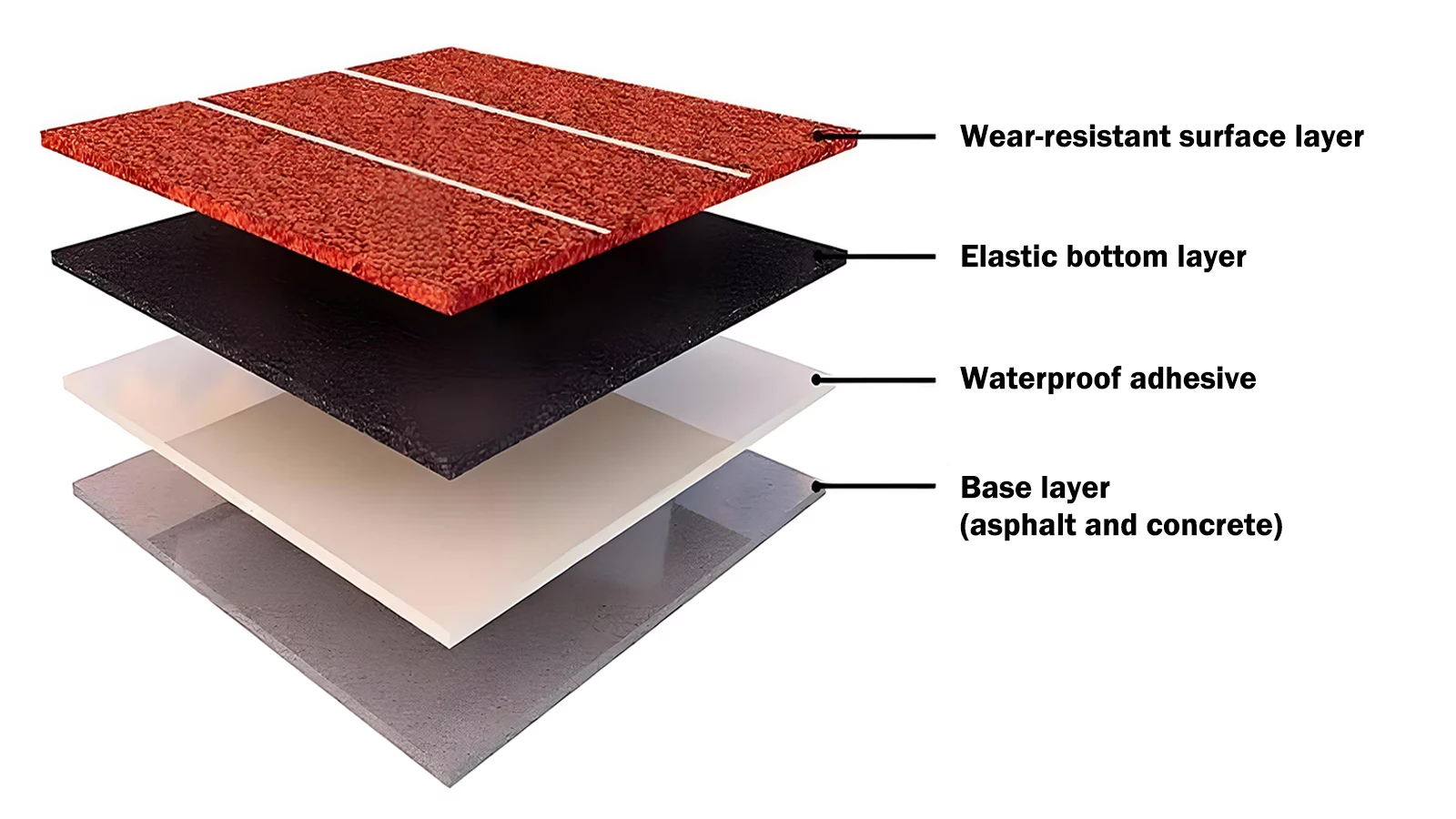

Description: 10 mm black SBR base/matting, PU 2:1 and 0.5-1.5 EPDM granule sprayed surface

Si-PU surface topcoat protection can be added.

| Product Name | Breathable System Running Track | Product rubber content | Top/25% (±1%), Bottom/20% (±1 %) |

| Feature | First choice for all schools and rainy areas, no bubbling, Economical | Impact absorption(%) | 40%(±1%) |

| Base | Cement or asphalt | Vertical deformation(mm) | 1.6mm(±0.1mm) |

| Color | Red, Blue, Purple, Green and customized | Tensile strength(Mpa) | 0.7Mpa(±0.1Mpa) |

| Thickness | 9-15.9MM(or customized) | Tensile elongation(%) | 91%(±5%) |

| Warranty | 2 Years | Shore hardness(°) | 55° |

| Certificate | IAAF | Anti-slip value | ≥47 BPN20℃ |

| Application | Stadium, sports ground, sport center, schools, jogging park and so on. | Fire resistance | 1 Grade |

Breathable running track by plastic bonded waste rubber environmental protection particles for the bottom layer, the surface layer with polyurethane particles and plastic slurry mix spraying and become. In addition to the advantages of other forms of water permeability, breathable type, but also can be used all-weather, it is the most economic, the most cost-effective, and there will be no bulging phenomenon occurs, but also reduces the basic capital investment, very suitable for training use of the athletic field laying.

1. Quick drying after rain: the structure is breathable and water permeable, rainwater can quickly seep into the bottom layer and drain away, and can be used again in a short time after the rain.

2. Safe and non-slip: the surface particle texture provides good friction, effective non-slip, reducing the risk of sports injuries.

3. Environmentally friendly and healthy: the material meets the environmental protection standards, no irritating odour, to protect the user’s health and environmental friendliness.

4. Durable and easy to maintain: stable structure, strong weather resistance (sun, frost), simple routine maintenance (easy to clean, repair).

5. Economical and practical: Compared with the full plastic runway, the amount of material is less, the construction cost is relatively low, and the cost performance is higher.

6. Quick construction: adopting paving process, the construction cycle is relatively short, and it can be put into use quickly.

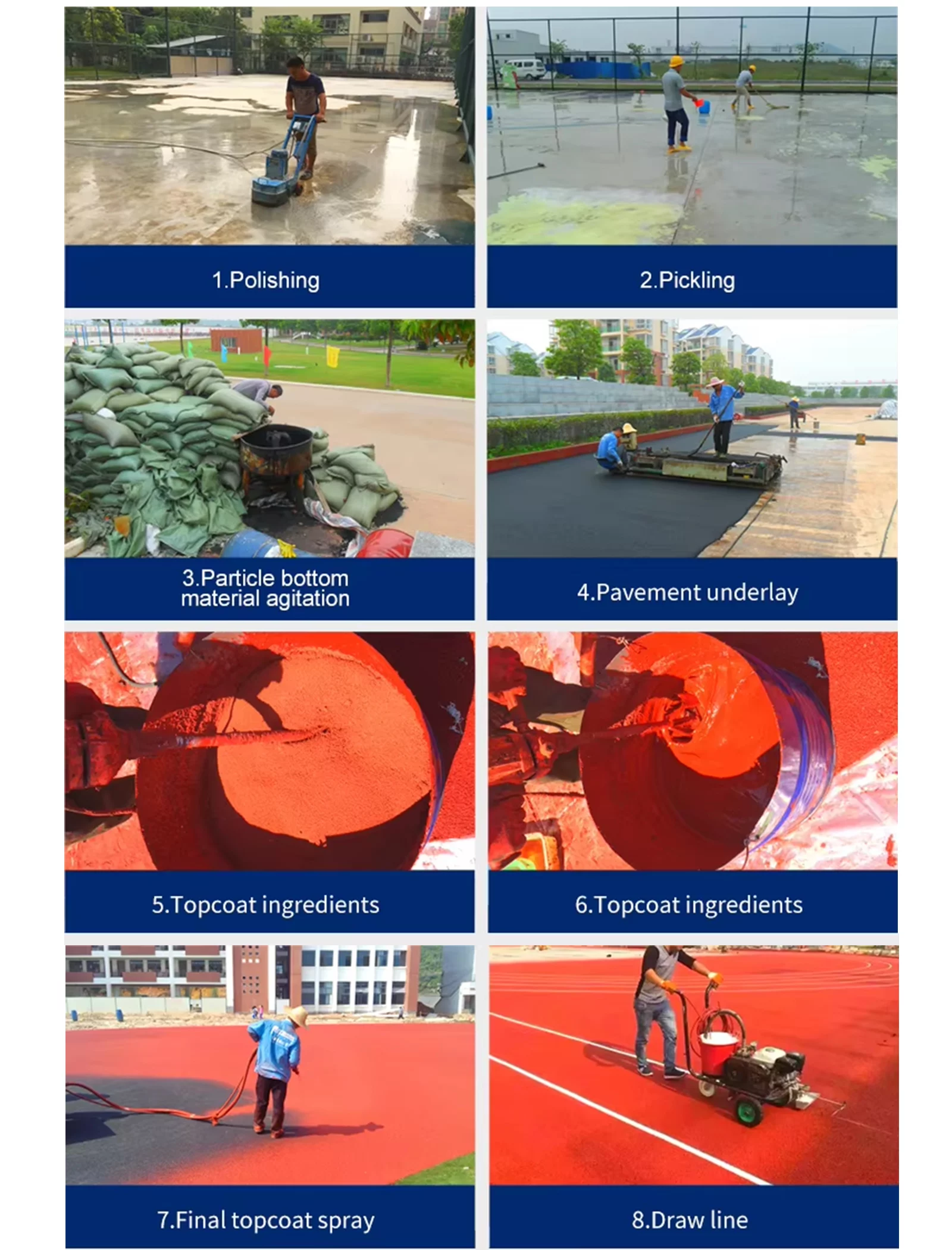

1. Clean the foundation (concrete or asphalt) to ensure that it is clean, dry, free of grease and loose.

2. Check that the foundation levelness, slope and strength meet the requirements (no water, no cracks, no sanding).

3. Repair defects (if any).

1. Apply special one-component glue (primer) to enhance the adhesion between the surface layer and the foundation.

1. Mix EPDM granules + one-component glue in specific ratio (e.g. 6:1 or 7:1) in a mixer well.

2. Transport the mixture to the site and spread it evenly (manually or mechanically).

3. Use special paver or scraper to level and control the thickness (usually 10-13mm).

1. Mix EPDM granules + one-component glue + color paste evenly according to the proportion (usually the proportion of granules is higher).

2. Use professional sprayer to spray 2-3 times evenly and crosswise.

1. After spraying, natural conservation curing at least 24-48 hours (depending on the weather and glue requirements).

2. During this period, it is strictly prohibited to step on it, pour water on it and pollute it.

1. Measure and place the line accurately according to the design drawings.

2. Use special marking paint to spray or paint white/other color marking lines.

1. Thoroughly clean the site of debris.

Tel:+86 1375 1210 938

Tel:+86 1375 1210 938 Whatsapp:+86 1375 1210 938

Whatsapp:+86 1375 1210 938 Telegram:+86 1375 1210 938

Telegram:+86 1375 1210 938 E-mail: ceo@dc-surface.com

E-mail: ceo@dc-surface.com Add:No:332 Dalang Town Dongguan City China 523000

Add:No:332 Dalang Town Dongguan City China 523000